DL06K Interim Tire-4 Diesel Engine Disassembly and Reassembly of Major Components

81

3.2.6. Crankshaft .

1) Inspection of crankshaft

a) Defect check

z Check the scratch or crack of the crankshaft journal and crank pin with naked

eyes.

z Check crack of the crankshaft through the magnetic particle inspection test and

crack detection by penetration of penetrant (color check). If any crack is found,

replace the crankshaft.

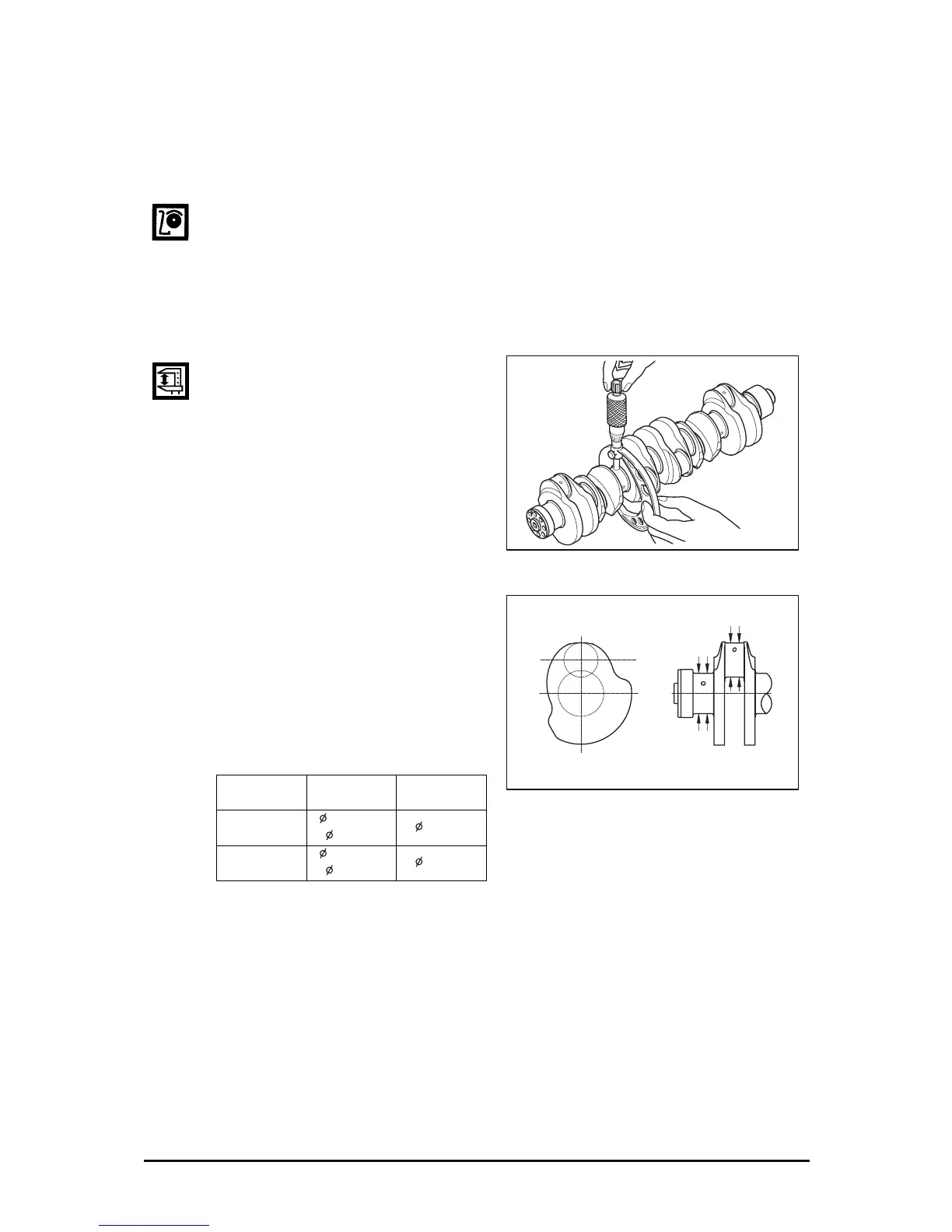

b) Wear measuring

z With an outside micrometer measure

the diameter of the crankshaft journals

and pins in the directions as shown,

and compare the measured values to

determine the amount of wear.

z If the amount of wear is beyond the

limit, have the crankshaft ground and

install undersize bearings.

z However, if the amount of wear is

within the limit, you can correct the

wear using an oil stone or oiled

grinding paper of fine grain size. (Be

sure to use grinding paper which has

been immersed in oil.)

(mm)

Standard Limit

Journal

diameter

79.905 ~

79.925

78.905

Pin

diameter

68.924 ~

68.944

67.924

EH6OM026

A

A

B

B

B

B

EH6OM033

Loading...

Loading...