DL06K Interim Tire-4 Diesel Engine Disassembly and Reassembly of Major Components

69

3.2. Inspection and Measurement on Major Parts

3.2.1. Cylinder block

z Clean the cylinder block thoroughly, and check for any crack or damage.

z If there is any crack or severe damage, replace it and if there is minor one,

correct it.

z Check for any clogging or corrosion in the oil passage and water passage.

z Carry out a leakage test for any crack or air leaking. (Hydraulic test)

z Plug each cylinder block’s water and oil discharge ports, and apply the air

pressure of about 4 kg/cm2 to intake port and soak it in water for about 1 minute

to check if there is any leakage. (Water temperature : 70 °C)

3.2.2. Cylinder head

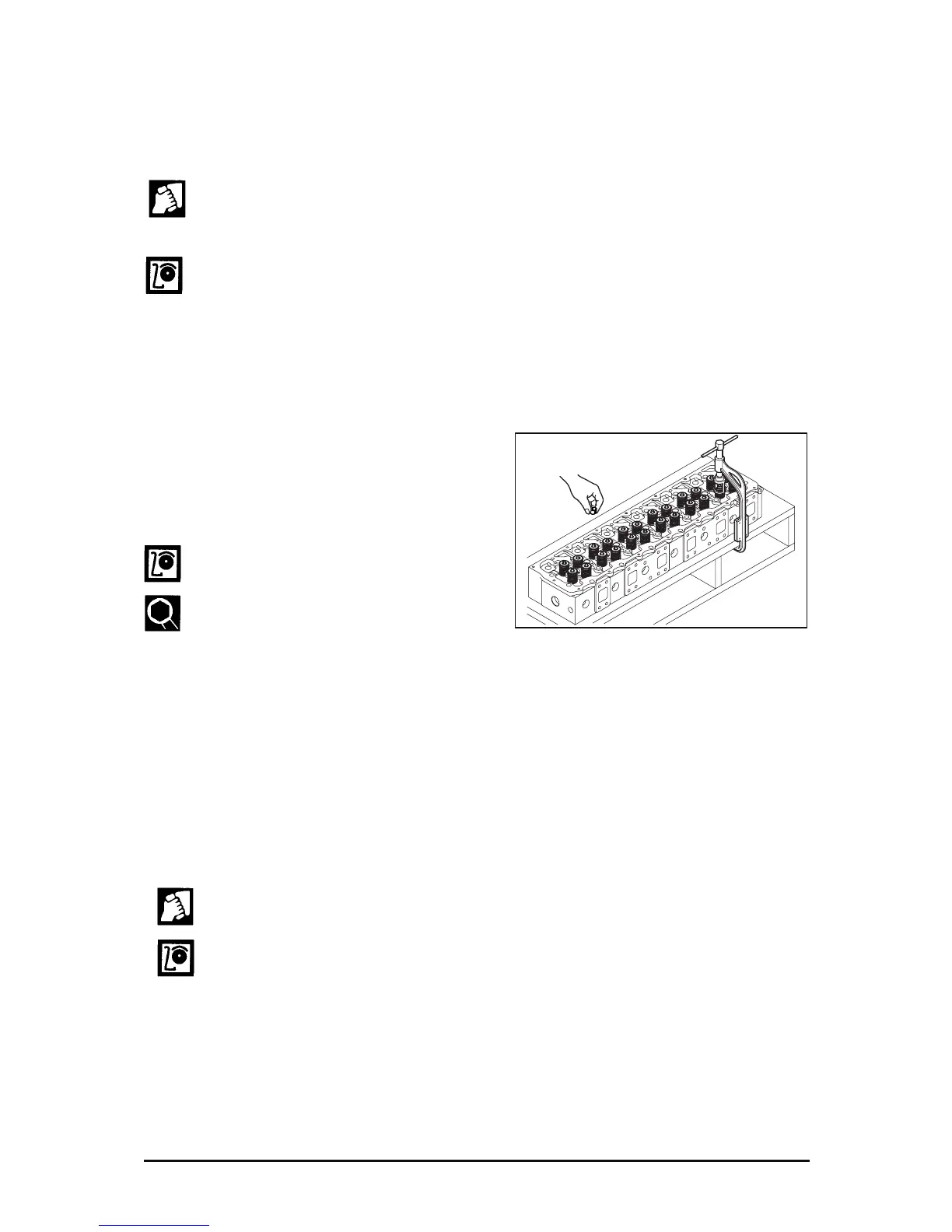

1) Disassembly

z Disassemble the cylinder assembly,

and put it on the shelf for assembly or

clean lathe.

z Prevent any damage to gasket’s

contact surface of the cylinder head.

z Disassemble the cotter pin, spring,

spring seat pushing valve spring by a

special tool.

Assembly tool item number :

EF.123-065A

z Pull out the intake and exhaust valves.

z The disassembled parts are kept laid in turn.

z Disassemble the valve stem seal.

2) Inspection of cylinder head

a) Check for the cylinder head.

z Remove carbon from the cylinder head lower surface, and then should be careful

not to scratch the surface.

z Check any crack or damage that can not found by naked eyes through the

hydraulic or magnetic particle test.

EJ9OM080

Loading...

Loading...