4. Regular inspection

61

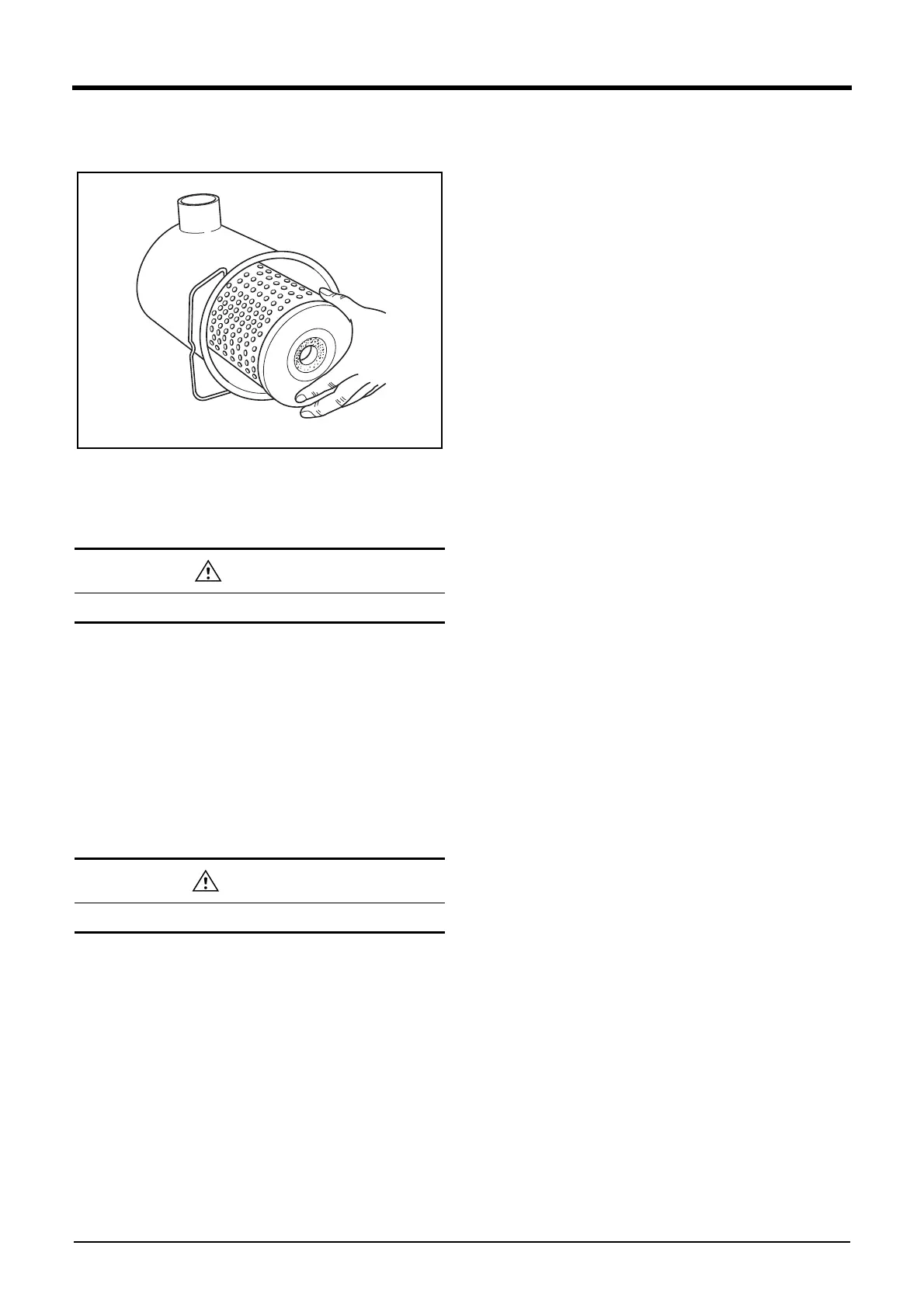

Changing the air filter element

1. Remove the hex nut, remove the dirty element.

DV2213030A

2. Replace with a new one or wash it.

3. Using a wet rag, wipe the inside of the filter housing.

4. The sealing contact of element.

Turbocharger

The Turbocharger does not need a specific maintenance.

Whenever replacing the engine oil, check oil pipe for leakage

or clogging.

• You should handle the air filter with special care to

prevent foreign substance from getting in.

• The turbocharged compressed air and exhaust gas pipe

should be checked periodically. Air leakage causes

engine overheat, so repair is required.

• If the impeller is severely contaminated, soak only the

wheel in a solvent and clean it with a rigid brush thor-

oughly. Here, be sure to soak only impeller, and the

turbocharger should be supported by a bearing housing,

not by an impeller.

Routine check and serving the turbocharger

The turbocharger performance is determined by mainte-

nance state of the engine. So you should regularly perform

inspection and check as specified.

1. Intake system

For the intake system, the air filter should be carefully

managed. For a wet type air filter, the intake resistance

should be small as possible.

2. Exhaust system

For the exhaust system, when exhaust gas leaks from

the exhaust pipe or turbocharger joint, supercharging effi-

ciency is lowered. So you need to pay attention to

prevent gas leakage and burn. Heat resistant nuts are

used for parts which are highly heated during operation,

such as the turbine seal, and the nuts should not be

mixed with other nuts. The screw burn prevention paint

should be applied to the assembly nuts of the specified

positions.

3. Fuel system

If the spray status of the fuel injection nozzle is not good,

or the injection timing is not correct, the exhaust gas

temperature increases to give a negative impact on the

turbocharger. So, the nozzle should be tested.

4. Lubrication system

For the lubrication system, pay attention with the oil

quality and the replacement time of the cartridge of the oil

filter. Degradation of engine oil has bad effect on the

turbocharger, as well as the engine body.

Disassembly and cleaning a turbocharger

You can disassemble the turbocharger from the engine to

clean or inspect it. Here, be sure to seal the oil inlet and oulet

with a tape, etc.

Do not let dust come into the end of air filter.

Be careful not to bend it.

Loading...

Loading...