Maintenance of Major Components

- 118 -

2) P180LE series engine

(1) Injection pump : 65.11101-7302 (0 402 619 802 BOSCH)

–

Model : PE10P120A500LS7936 (0 412 629 815)

–

Governor : Ghana Control (DWA-2000)

–

Plunger & barrel : 2 418 455 545

–

Delivery valve : 2 418 559 045

–

Feed pump : FP/KD22P80-1 (0 440 008 090)

FP/KD22P78-2 (0 440 008 152)

–

Prestroke : 4.5

±

0.05 mm at 13

±

1.5 mm

(2) Nozzle holder assembly : 65.10101-7051 (0 432 131 667)/65.10101-7053(0 432 131 669)

(3) Nozzle : 65.10102-6047 (0 433 171 174)/65.10102-6070(0 433 171 169)

(4) Injection pipe : 65.10301-6055B, 65.10301-6056B

(5) Injection order : 1 – 6 – 5 – 10 – 2 – 7 – 3 – 8 – 4 – 9

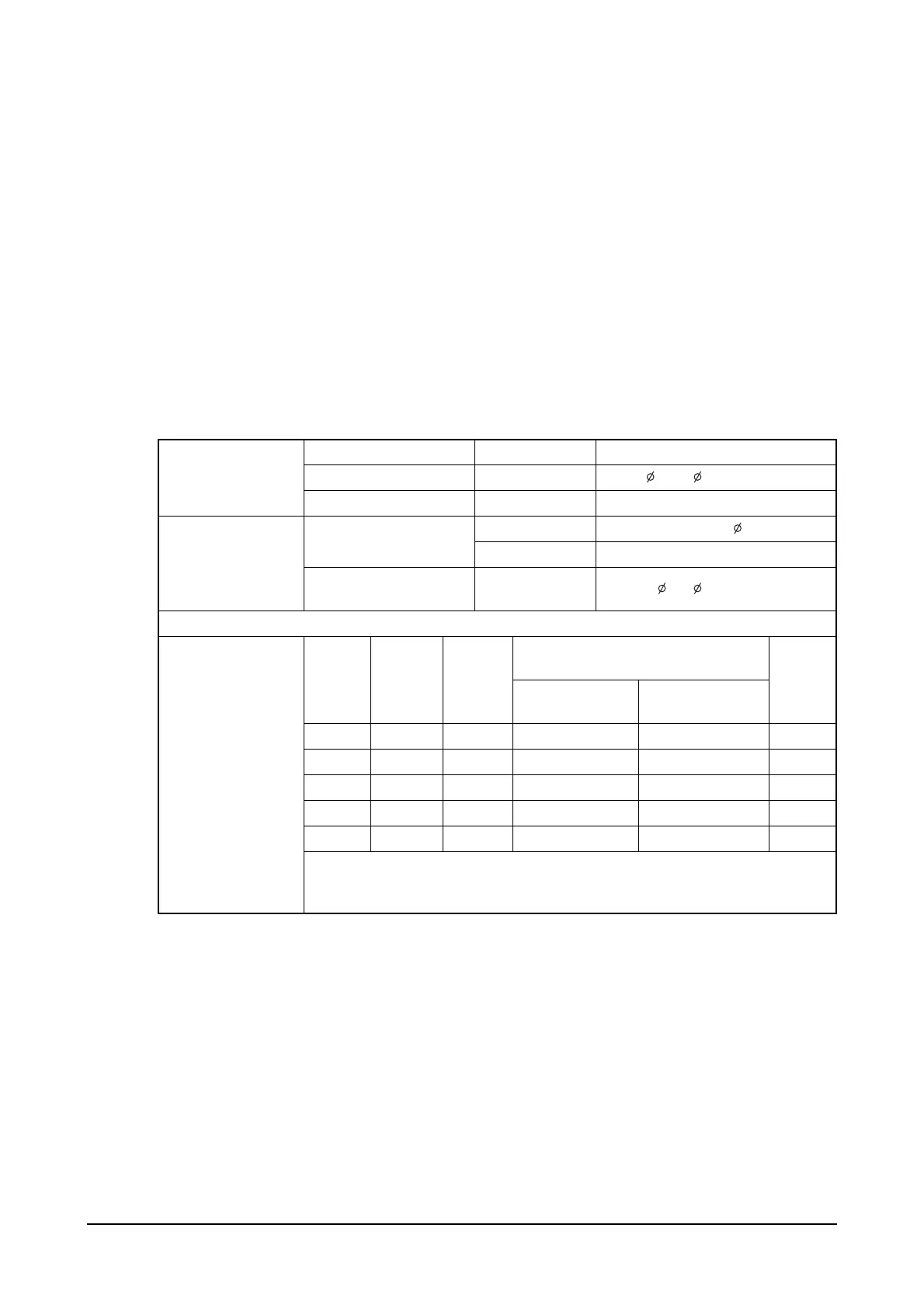

(A) Test condition for

injection pump

Nozzle & holder ass’y 1 688 901 105 Opening pressure : 208.5

±

1.5 bar

Injection pipe (ID ,OD ,L)

–

3.0 × 8.0 – 600 mm

Test oil ISO4113 Temperature : 40

±

5

°

C

(B) Engine standard

parts

Nozzle & holder ass’y

65.10101-7051 Nozzle (4 × 0.40)

285 kg/cm

2

Injection pipe(ID, OD ,L)

65.10301-6055

65.10301-6056

2 × 6 – 750 mm

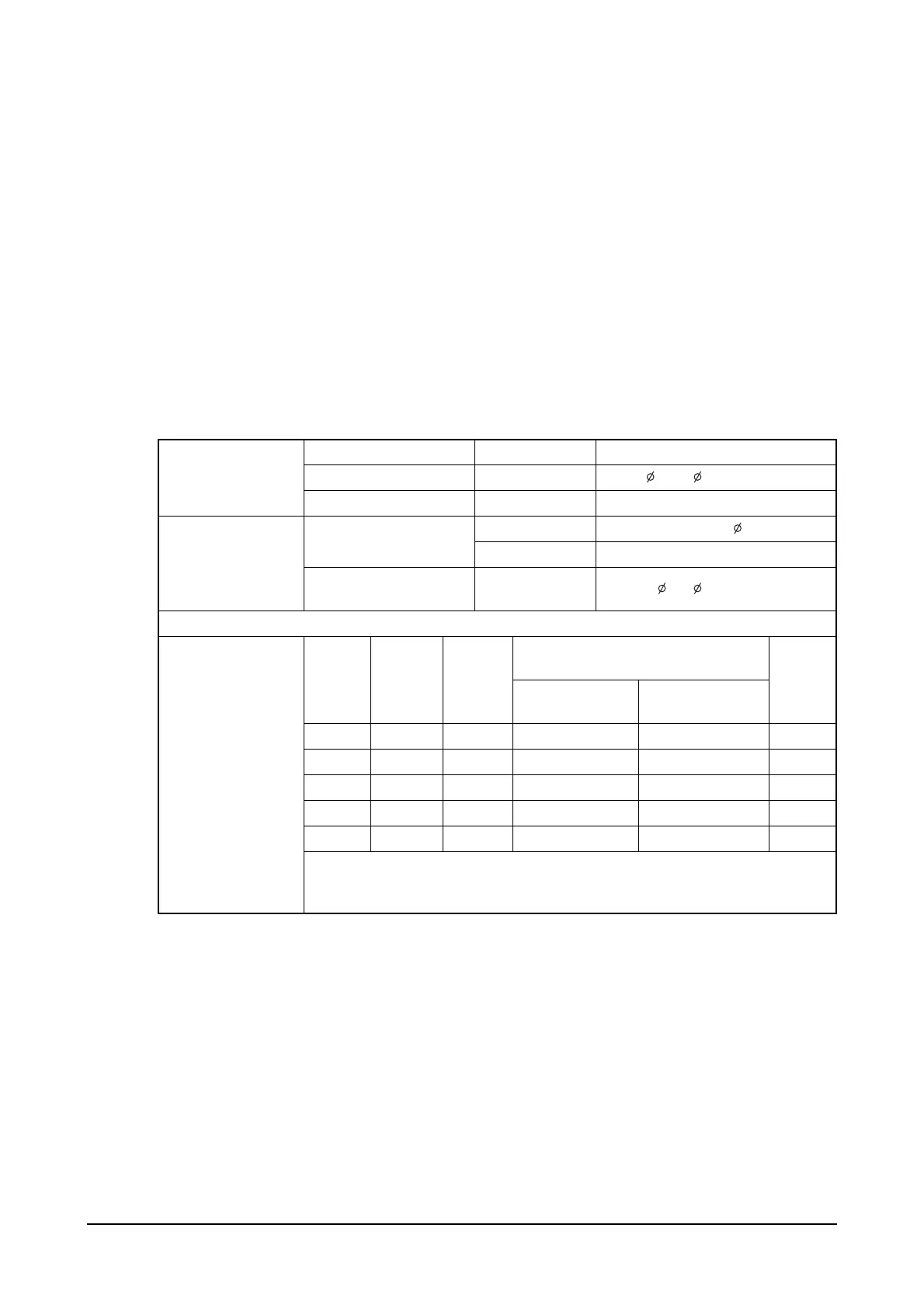

Rack diagram and setting valve at each point

Standby power

Check

point

Rack

position

(mm)

Pump

speed

(rpm)

Injection Q’ty on RIG

(mm

3

/ 1,000 st)

Press.

(mmHg)

(A) Test condition

for inj. pump

(B) Engine

standard parts

A 12.6 700 304

±

3

––

––– – – –

––– – – –

––– – – –

––– – – –

Boost pressure : zero boost

Loading...

Loading...