3360562 (A3-D-P)

3360562

© Dräger Safety UK Limited

Edition 05 – January 2019 (Edition 01 – June 2012)

Subject to alteration

Draeger Safety UK Limited

Ullswater Close Tel +44 1670 352 891

Blyth, NE24 4RG Fax +44 1670 356 266

United Kingdom www.draeger.com

5.2 Cleaning

CAUTION

Do not exceed 60 °C for drying, and remove components

from the drying facility immediately when dry. Drying time

in a heated dryer must not exceed 30 minutes.

Do not immerse pneumatic or electronic components in

cleaning solutions or water unless following the internal

cleaning procedure in Section 5.2.2.

Thoroughly dry the lung demand valve after cleaning and

disinfecting.

For information about suitable cleaning and disinfecting

agents and their specifications refer to document 9100081

on www.draeger.com/IFU.

Refer also to the instructions for use for the face mask and other

associated equipment.

● Use only clean lint-free cloths

5.2.1 External cleaning

1. Clean the lung demand valve manually using a cloth

moistened with cleaning solution to remove excess dirt.

2. Rinse all components thoroughly with a cloth moistened with

clean water to remove all cleaning and disinfecting agents.

3. Dry all components using a dry cloth, in a heated dryer or in air.

4. Contact service personnel or Dräger if disassembly of the lung

demand valve is required.

5.2.2 Internal cleaning and disinfecting

CAUTION

Internal cleaning and disinfecting may only be carried out

by properly trained personnel. Disassembly of the lung

demand valve by untrained personnel is not permitted and

may damage the equipment.

Ultrasonic cleaning will damage the diaphragm. Dräger

recommend that ultrasonic cleaning methods are not used

for any part of the lung demand valve.

Cleaning solutions will eventually remove lubricants from moving

parts. Carry out functional tests following cleaning, disinfecting

and drying. Re-lubricate moving parts as required.

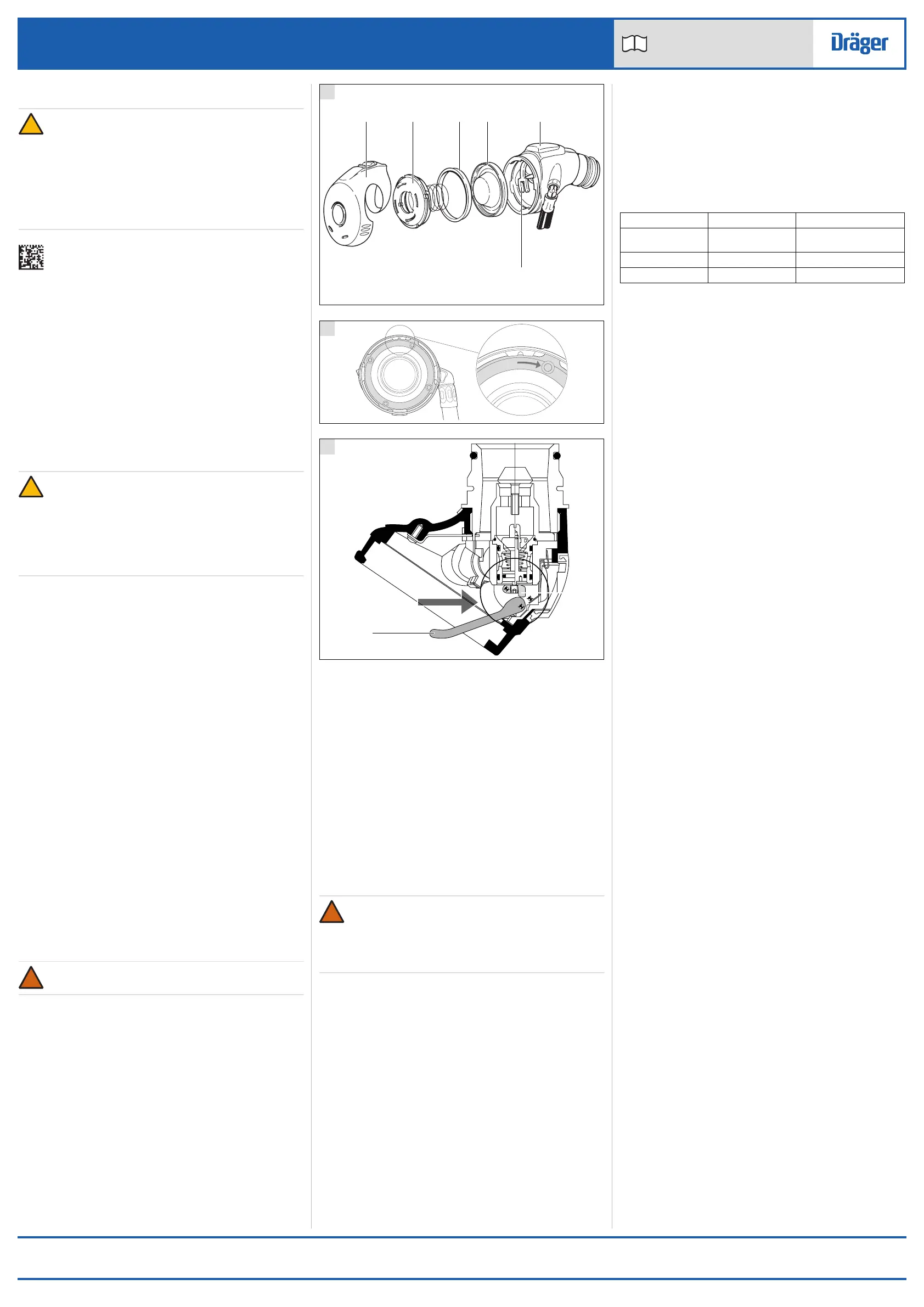

1. Disassemble the lung demand valve as follows:

a. Remove the rubber cover (Fig H, Item 1) from the front of

the lung demand valve housing. Twist the bayonet cap (2)

anticlockwise to remove it (a plate spanner is available

from Dräger for this task – see Section 9). Do not attempt

to remove the spring from the bayonet cap, and do not

stretch, compress or damage the spring during cleaning

and disinfecting (note that the spring is not fitted on

negative-pressure (N-type) lung demand valves).

b. Carefully grip the slip ring (Fig H, Item 3). If required, rotate

the slip ring until the external lugs are free from the

retaining lugs of the housing (Fig I). Remove the slip ring

from the housing.

c. Carefully grip the centre of the diaphragm (Fig H, Item 4)

between the thumb and forefinger. Tilt and remove the

diaphragm from the housing.

d. Replace the rubber cover on the front of the lung demand

valve to protect the balanced piston lever (6).

2. Immerse and manually agitate the lung demand valve,

diaphragm, slip ring and bayonet cap in a cleaning solution.

3. Rinse all parts in clean water.

4. Immerse and manually agitate all parts in a disinfecting

solution.

5. Remove the rubber cover from the front of the lung demand

valve and rinse all parts in clean water, taking care not to

damage the balanced piston lever.

6. Press the reset button (5) to switch off the lung demand valve

and then connect the demand valve hose to a medium-

pressure breathing air supply (minimum of 4 bar).

WARNING

Do not direct the airflow on to the face, eyes or skin.

7. Lightly press the balanced piston lever to blow away any

moisture.

8. Disconnect the air supply and dry all parts using a clean lint-

free cloth or a dedicated drying facility.

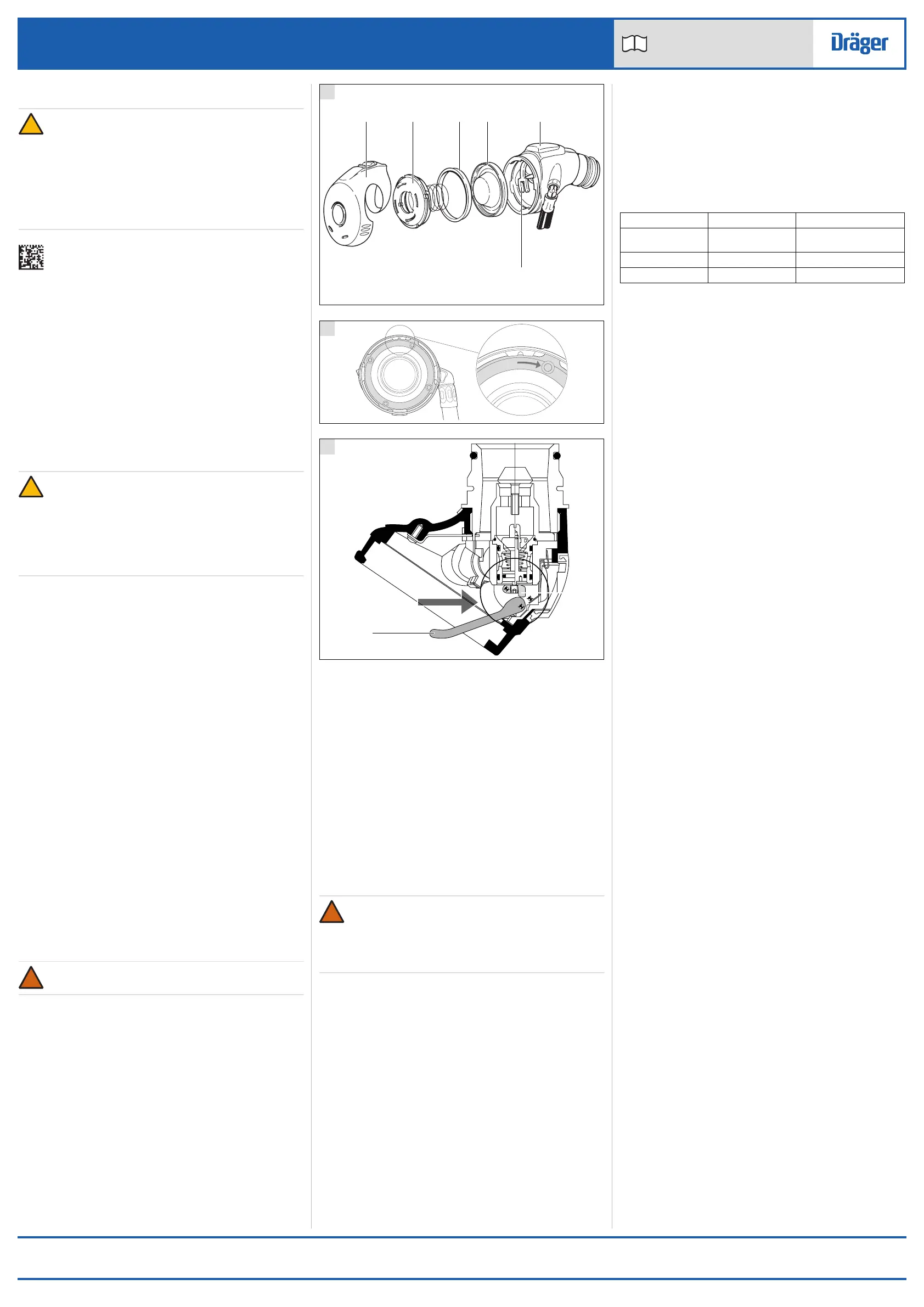

9. If re-lubrication of the moving parts is required, position the

main lever (Fig J, Item 1) and secondary lever (2) as shown.

Apply two short squirts of lubricant (Silkospray silicone

lubricant) to the circled area in the direction indicated by the

arrow.

10. Reassemble the lung demand valve as follows:

a. Carefully install the diaphragm into the lung demand valve

housing.

b. Carefully insert the profiled side of the slip ring into the

housing, ensuring that it sits inside the exterior bead of the

diaphragm.

c. Position the bayonet cap spring in the middle of the

diaphragm. Twist the bayonet cap clockwise to fit it to the

lung demand valve housing.

d. Replace the rubber cover on the front of the lung demand

valve.

11. Press the reset button to switch off the valve.

12. Carry out a full functional test of the lung demand valve (see

Section 5.4).

5.3 Visual inspection

Check that the lung demand valve is clean and undamaged. Pay

particular attention to levers, diaphragm, spring, hoses and

connectors. Typical signs of damage that may affect the operation

of the lung demand valve include impact, abrasion, cutting and

discolouration.

Report damage to trained service personnel or Dräger. Do not use

the lung demand valve until the faults are rectified.

5.4 Functional test

Test the lung demand valve as described in the functional and leak

test procedure in the breathing apparatus Instructions for Use.

WARNING

Failure of the breathing apparatus to meet any of the

standards or parameters described in the functional tests

indicates a system fault. Report the fault to trained service

personnel or contact Dräger. Do not use the breathing

apparatus until the fault condition is rectified.

5.5 Replacing the diaphragm

1. Remove the defective diaphragm and install the replacement.

Instructions for replacing the diaphragm are contained in the

internal cleaning procedure (see Section 5.2.2).

2. Carry out a full functional test of the lung demand valve (see

Section 5.4).

6 Storage

Store the equipment between -15 °C and +25 °C. Ensure that the

environment is dry, free from dust and dirt, and does not subject

the equipment to wear or damage due to abrasion. Do not store

the equipment in direct sunlight.

Route the medium-pressure hose in such a way that the bend

radius is not too small and the hose is not stretched, compressed

or twisted.

7 Disposal

When required, dispose of the lung demand valve in accordance

with national or local regulations for waste disposal.

8 Technical data

Technical data is available from Dräger.

9 Order list

Loading...

Loading...