Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:9

5.6 Replacing Medium Pressure Hose

5.6.1 Removing Medium Pressure Hose

Tools required

Screwdriver 3336222

Plate Spanner R26817

Retractor Tool 3310663

1 Disconnect demand valve from female quick release coupling of

equipment.

Note:

Fixed variants of the lung demand valves incorporate a medium pressure

hose fitted directly to the medium pressure outlet port of the pressure

reducer. These demand valves should be removed from the reducer.

For details of removal of hose from the reducer refer to the appropriate

section of the relevant C.A.B.E. Training Manual.

2

3

4

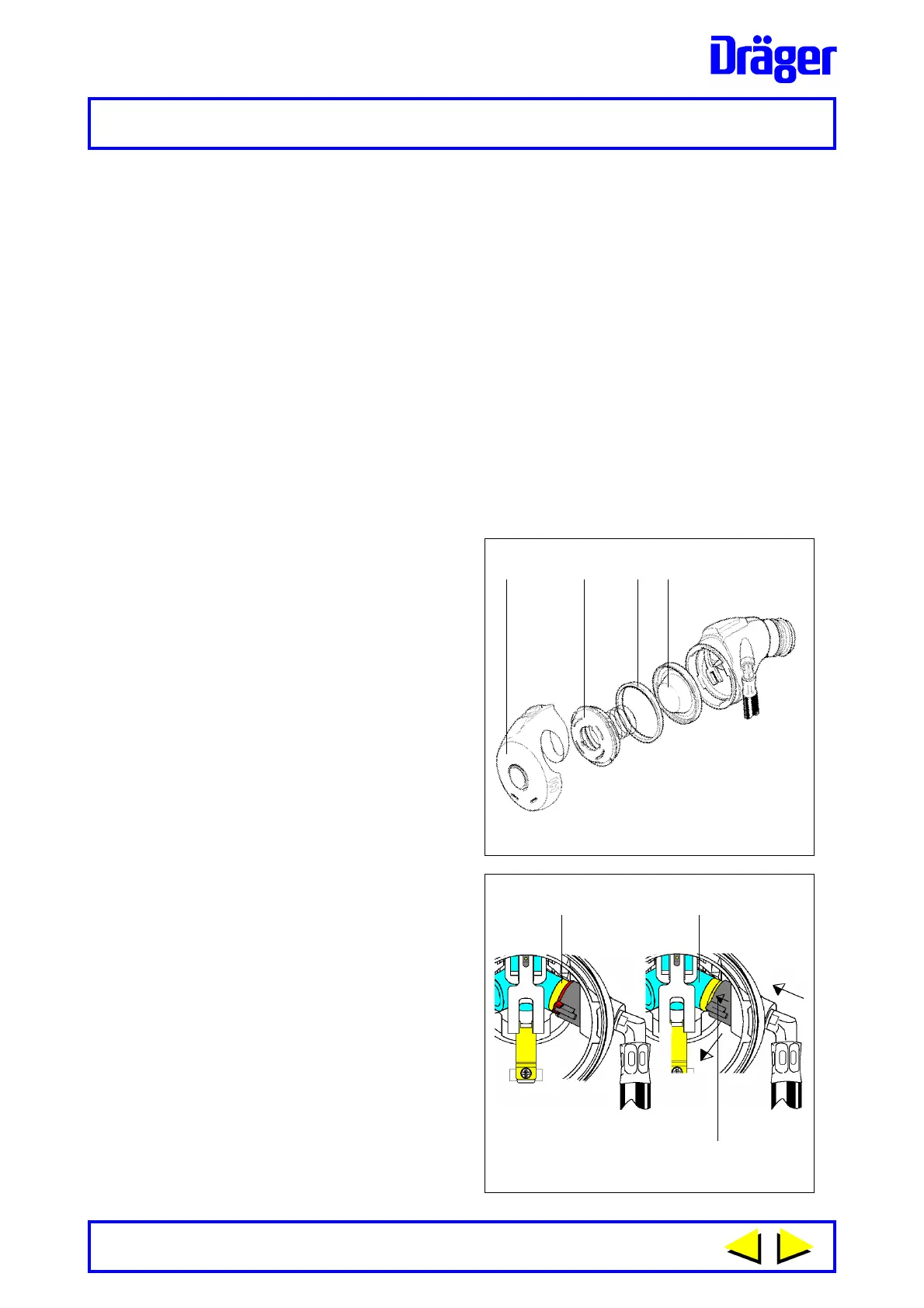

Fig. 5

0584

1

Refer to Figure 5.

(Type A illustrated)

2 Fold the rubber cover (1) from

front of lung demand valve.

Using plate spanner inserted into

radial slots of bayonet cap, turn

bayonet cap (2) counter-

clockwise and remove from

body of demand valve.

Note:

The positive pressure spring

remains attached to the

bayonet cap.

Do Not

remove

spring. Take care not to stretch

or distort the spring.

3 Using the thumb and forefinger

carefully grip the centre plate of

the diaphragm (3), tilt centre

plate and lift the diaphragm from

the body of the lung demand

valve. Remove slip ring (4).

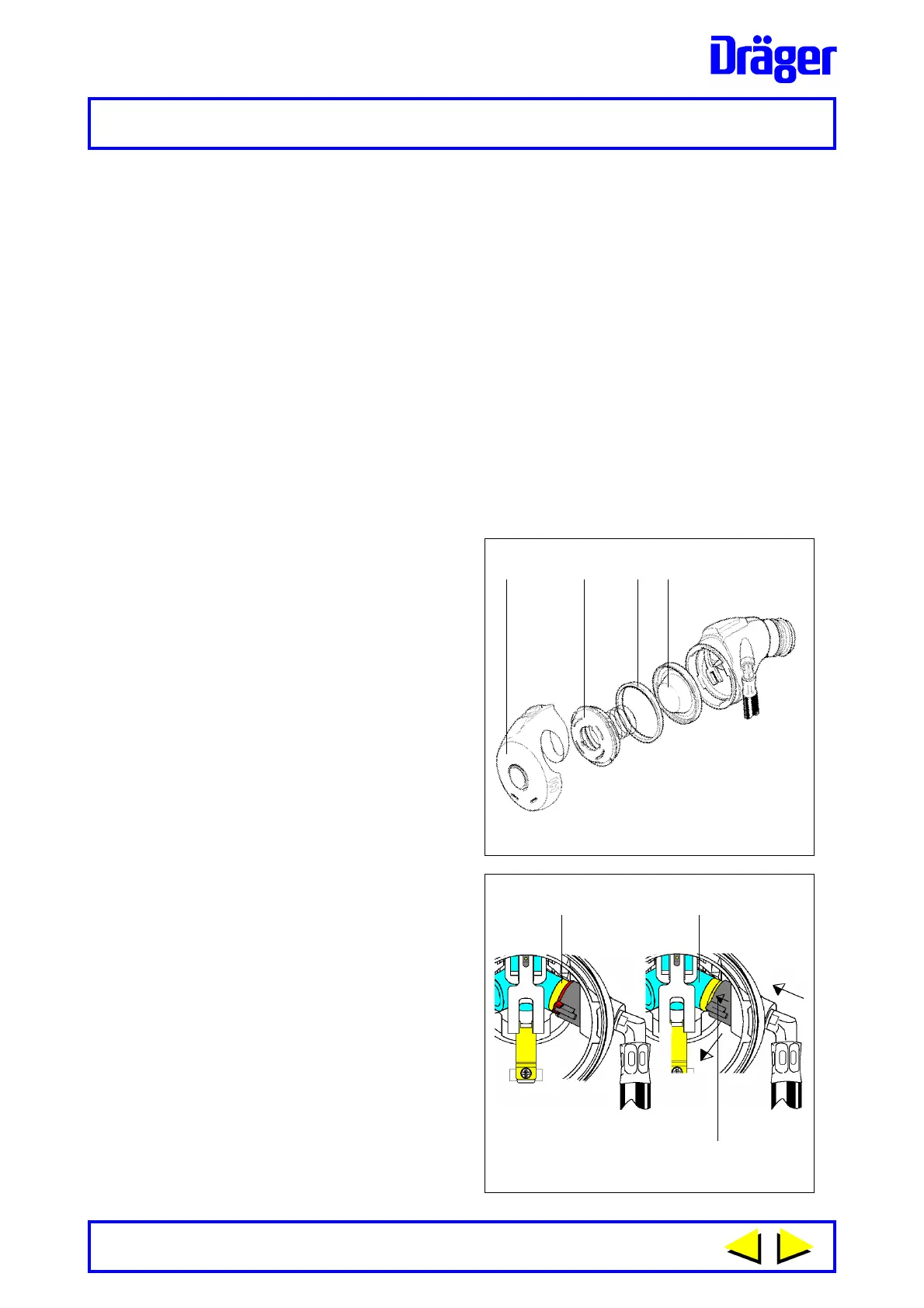

Refer to Figure 6.

Important Note: Spacer (1) must be

removed before attempting to

remove Clip (2).

Fig. 6

1134

1

2

3

Loading...

Loading...