Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:8

5.5 Replacing Positive Pressure Spring - Types A and AE

Tools Required

Plate Spanner

R26817

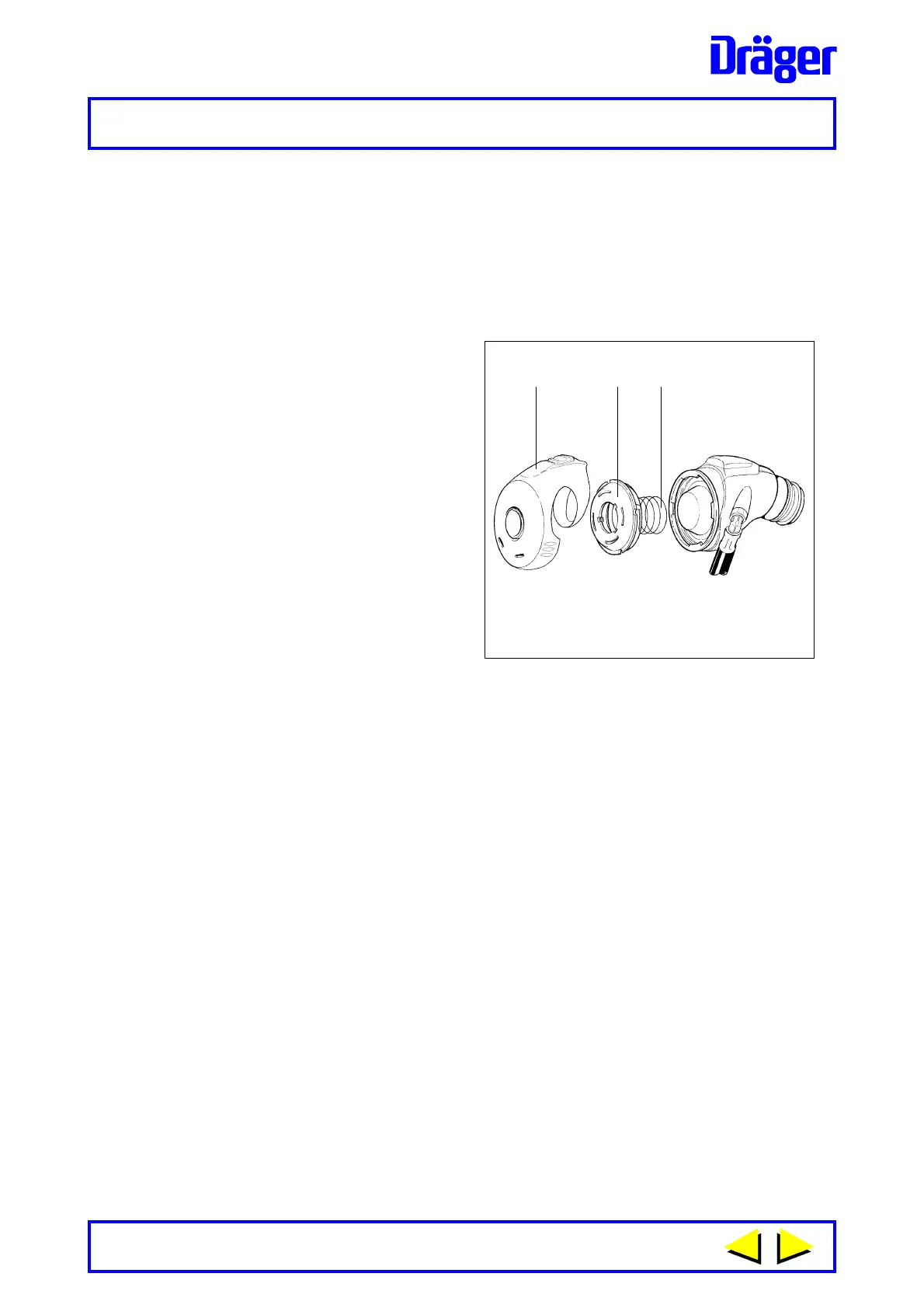

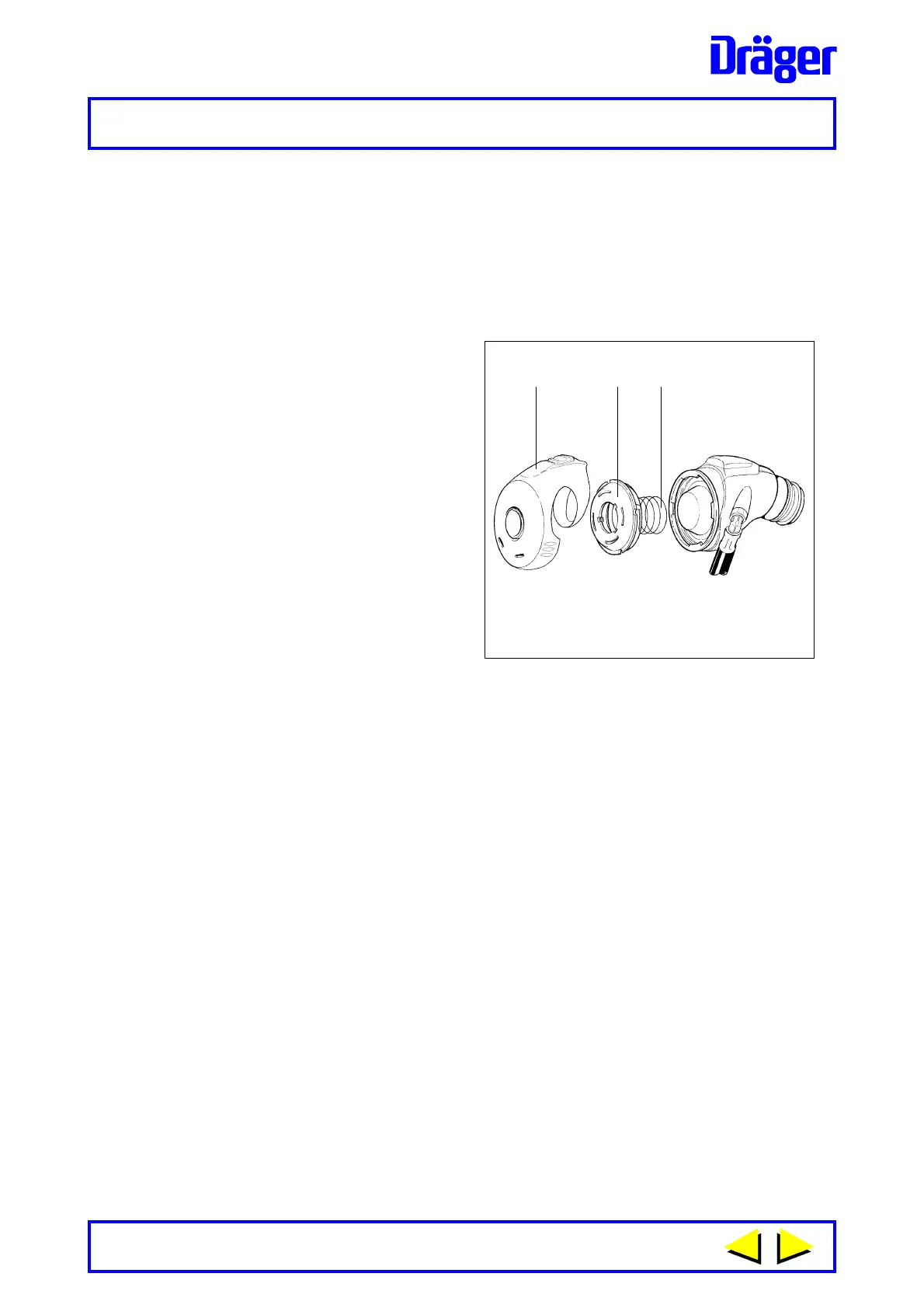

Refer to Figure 4 - Type A Demand Valve Illustrated.

1 Fold rubber cover (1) from front

of lung demand valve. Using

plate spanner, inserted into

radial slots of bayonet cap, turn

bayonet cap (2) counter-

clockwise and remove from

body of demand valve.

Note:

The positive pressure spring (3)

remains attached to the

bayonet cap.

2 When looking inside the

bayonet cap and with the axial

retaining leg of the spring at the

11 o’clock position, unhook the

first coil of the spring from the

retaining lug at the 2 o’clock position, then from the retaining lug at the

6 o’clock position. Turning the spring slightly anti-clockwise removes the

coil from the final retaining lug (10 o’clock) allowing the axial retaining

leg of the spring to be removed from the hole in the bayonet cap. Discard

the defective spring.

3 Fit new spring as follows. When looking inside the bayonet cap and with

the retention hole for the axial retaining leg of the spring at the 11 o’clock

position, insert the axial retaining leg of the spring into the retention hole

in the bayonet cap. Hook the first coil of the spring under the retaining

lug at the 10 o’clock position - then under the retaining lug at the 6

o’clock position - then under the retaining lug at the 2 o’clock position.

Note:

Ensure only one coil diameter of the spring is located under each of the

three retaining lugs.

4 Check that the diaphragm and slip ring are still correctly located in the

body of the lung demand valve then locate positive pressure spring of

bayonet cap into the recess in centre plate of diaphragm. Using plate

spanner, inserted into radial slots of the bayonet cap, lock bayonet cap

to body then fold rubber cover back over the front of the demand valve.

5 Press re-set button and then connect demand valve to equipment and

carry out Leak Test and Functional Test.

Fig. 4

1133

32

1

Loading...

Loading...