Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:7

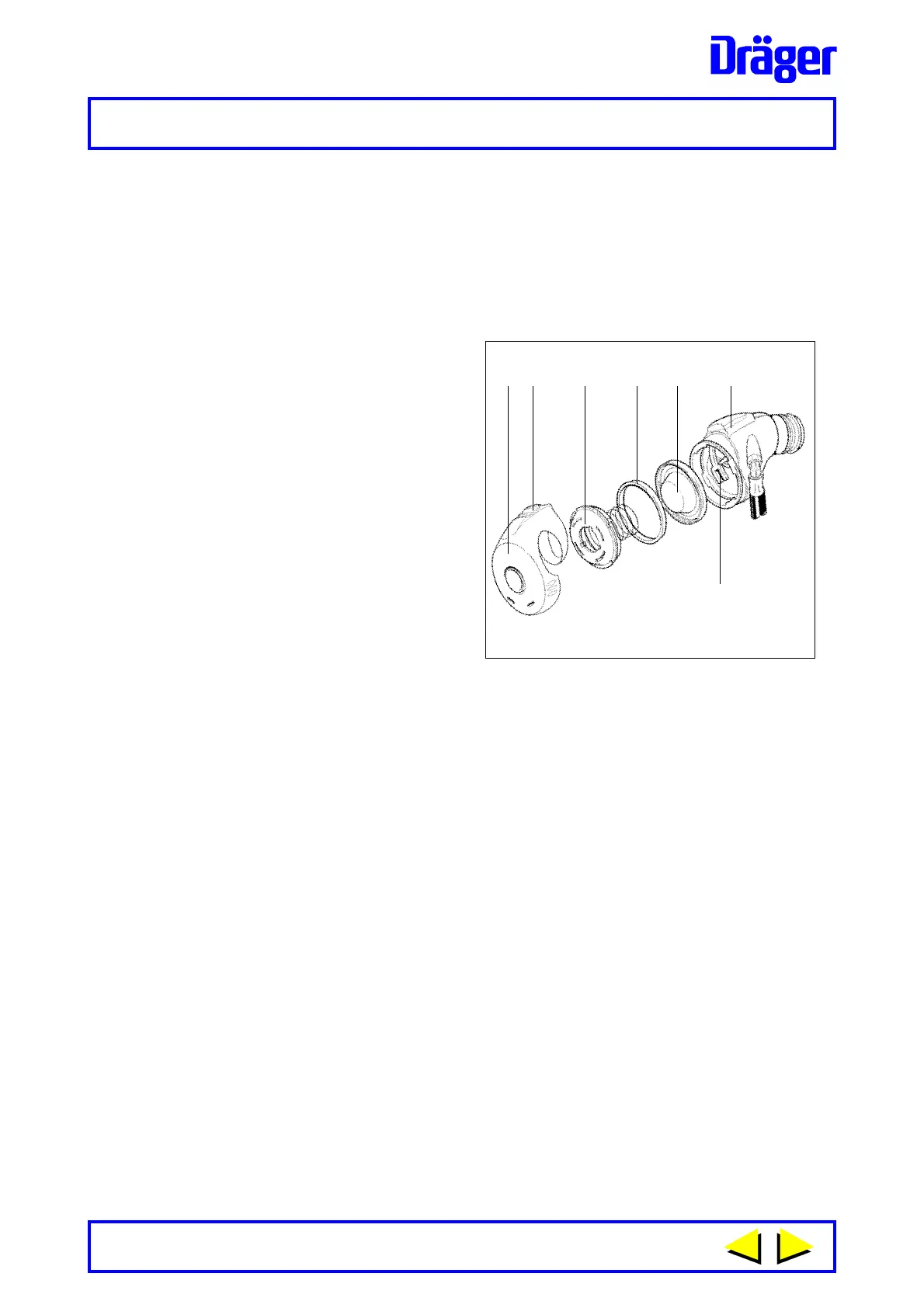

1

2

3

4

5

6

Fig. 3

0584

6

5.4 Replacing Diaphragm

Tools Required

Plate Spanner

R26817

Refer to Figure 3 - Type A Demand Valve Illustrated.

1 Fold rubber cover (1) from front

of lung demand valve. Using

plate spanner, inserted into

radial slots of bayonet cap, turn

bayonet cap (2) counter-

clockwise and remove from

body of demand valve.

Note:

Types A and AE - the positive

pressure spring remains

attached to the bayonet cap.

Do Not

remove spring. Take care

not to stretch or distort the

spring.

2 Using the thumb and forefinger

carefully grip the centre plate of

the diaphragm (3), tilt centre

plate and lift the diaphragm from

the body of the lung demand

valve. Remove slip ring (4).

Discard defective diaphragm.

3 Carefully locate outer bead of new diaphragm into groove in the body of

the demand valve. Locate tapered side of slip ring into recess in bead of

diaphragm.

Types A and AE - Locate positive pressure spring of bayonet cap into the

recess in centre plate of diaphragm.

Using plate spanner, inserted into radial slots of the bayonet cap, lock

bayonet cap to body then fold rubber cover back over the front of the

demand valve.

4 Press re-set button of type A and AE demand valves. Connect demand

valve to equipment and carry out Leak Test and Functional Test.

Loading...

Loading...