Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:22

5.9 Lubrication of Connector Assemblies - M40 and M45

Important Note: Immersing of components will eventually remove lubricants.

Following cleaning, disinfecting and drying it is recommended that

functional tests be carried out. Re-lubricate as required. Refer to Page 5:3.

Tools required

Plate Spanner R26817

No. 2 Posi-Driv Screwdriver 3331245

Connector Tool 3310679

5.9.1 Removing Connector Assemblies from LDV- M40 and M45

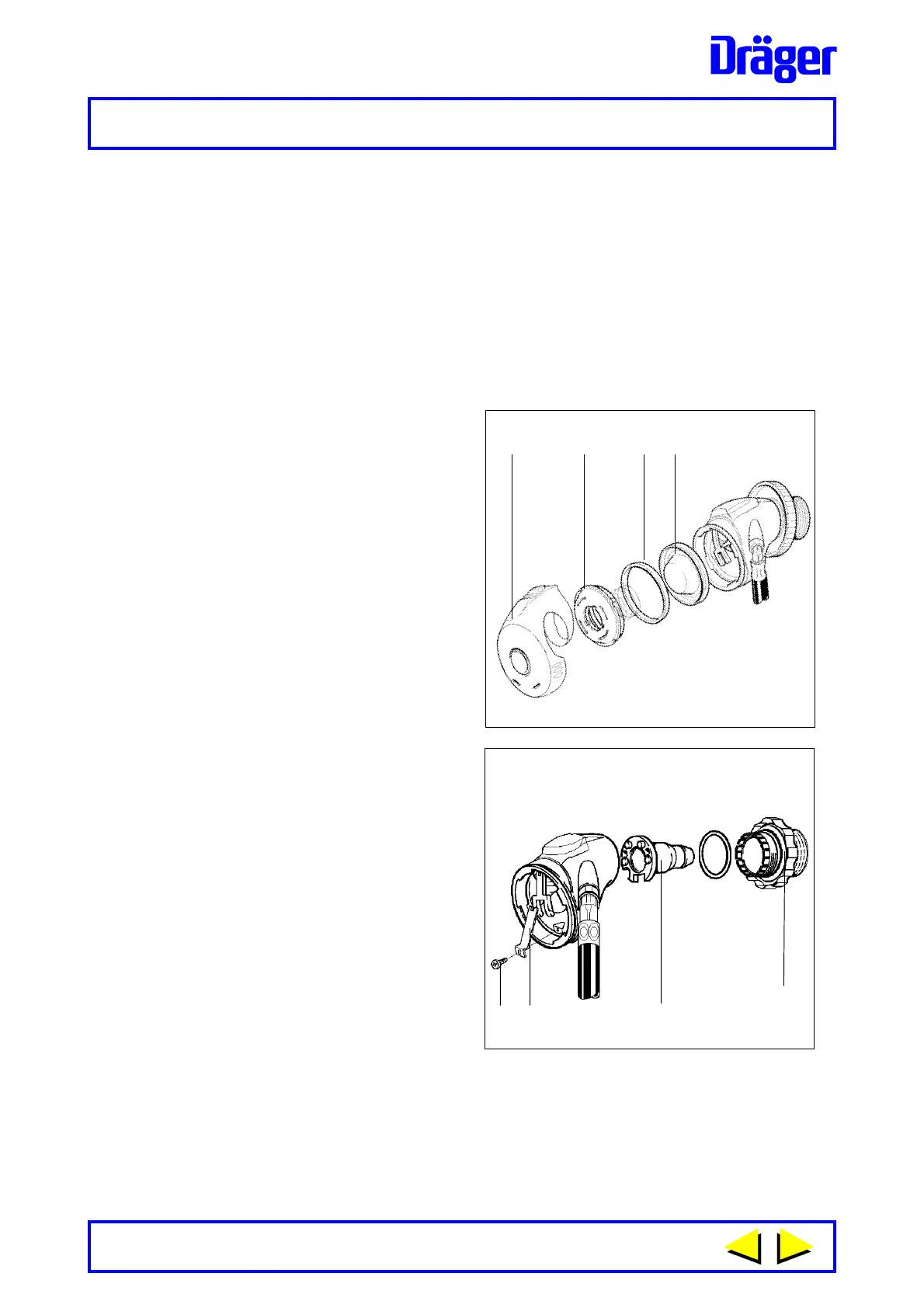

1186

12

3

4

Fig. 26

Note: Do Not

attempt to remove connectors with the locking arm located in

the castellation of the connector.

Use connector tool (3310679) - insert pins of tool into the swivel connector

and rotate to align slots of fixed end of connector and insert pins - unscrew

(anti-clockwise) to remove screw type connector and handwheel assembly

from demand valve body. Remove injector pipe (4).

12 3

4

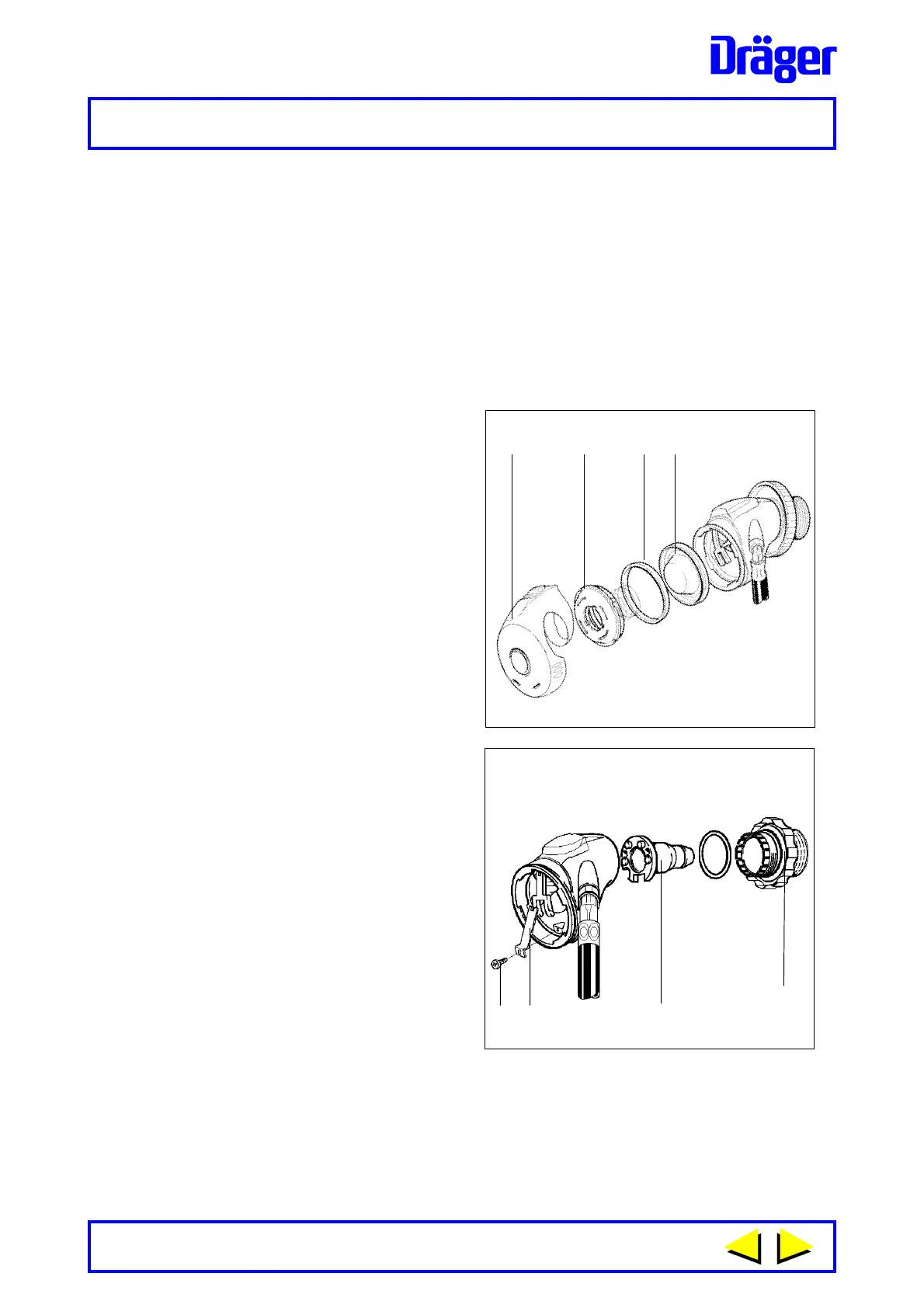

Fig. 25

0619

1 If required disconnect demand

valve from the female quick

release coupling of equipment.

Refer to Figure 25.

2 Fold back the rubber cover (1)

then using plate spanner inserted

into radial slots of bayonet cap,

turn bayonet cap (2) counter-

clockwise and remove from body

of demand valve. Using the

thumb and forefinger carefully

grip the centre plate of the

diaphragm (3), tilt centre plate

and lift the diaphragm from the

body of the lung demand valve.

Remove slip ring (4).

Note:

Type M45 - the positive pressure

spring remains attached to the

bayonet cap.

Do Not

remove

spring. Take care not to stretch

or distort the spring.

Refer to Fig. 26.

3 Using posi-driv screwdriver

unscrew retaining screw (1) until

the locking arm (2) is able to be

withdrawn from castellation of

connector (3).

4 Remove connector as follows.

Loading...

Loading...