- 11 -

It is necessary to check the safety valve each time before putting it into operation. It is checked

by manual moving of the membrane from the seat, turning the make-and-break device button

always in the direction of the arrow.

After being turned, the button must click back into

a notch. Proper function of the make-and-break device results in water draining through the

safety valve outlet pipe. In common operation, such a check needs to be implemented at least

once a month, and after each heater shutdown for more than 5 days. Water may be dripping

off the drain pipe of the safety valve; the pipe must be open into the air, pointed down;

environment temperatures must not drop below zero. When draining the heater, use the

recommended drain valve. First, close the water supply into the heater.

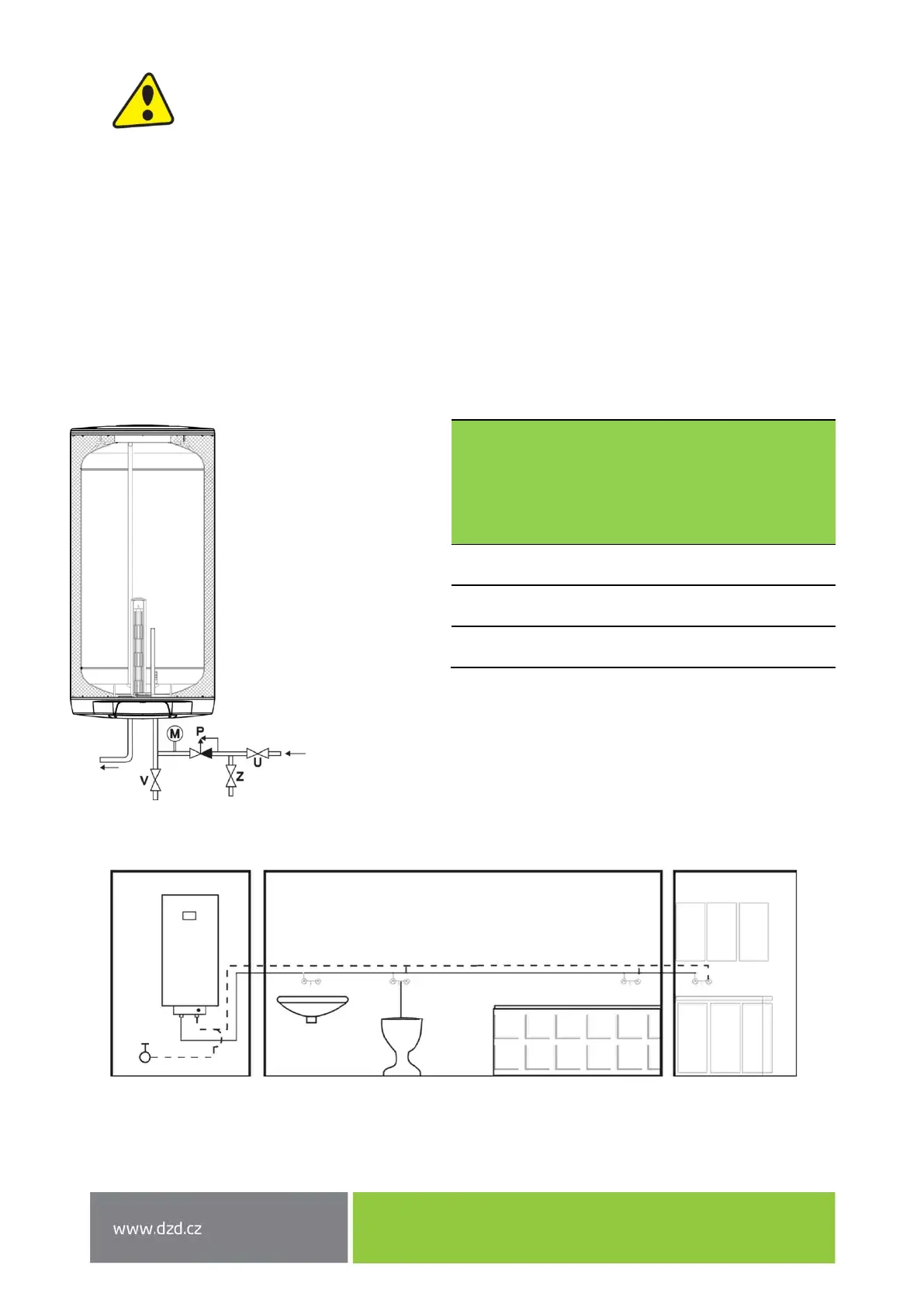

Find necessary pressure values in the below Table 4. For proper safety valve operation, a backflow valve

(

Figure 6) must be mounted on the inlet pipes, preventing spontaneous heater draining and hot water

penetrating back into the water main. We recommend that the hot water distribution from the heater was

as short as possible to minimise heat losses. At least one demountable joint must be mounted between

the tank and every supply pipe. Adequate piping and fittings with sufficiently dimensioned maximum

temperature and pressure values must be used.

Table 4

Heaters must be provided with a discharge valve

mounted on the cold service water inlet to the heater

for potential disassembly or repair. When assembling

the security equipment, follow the standard.

Figure 6

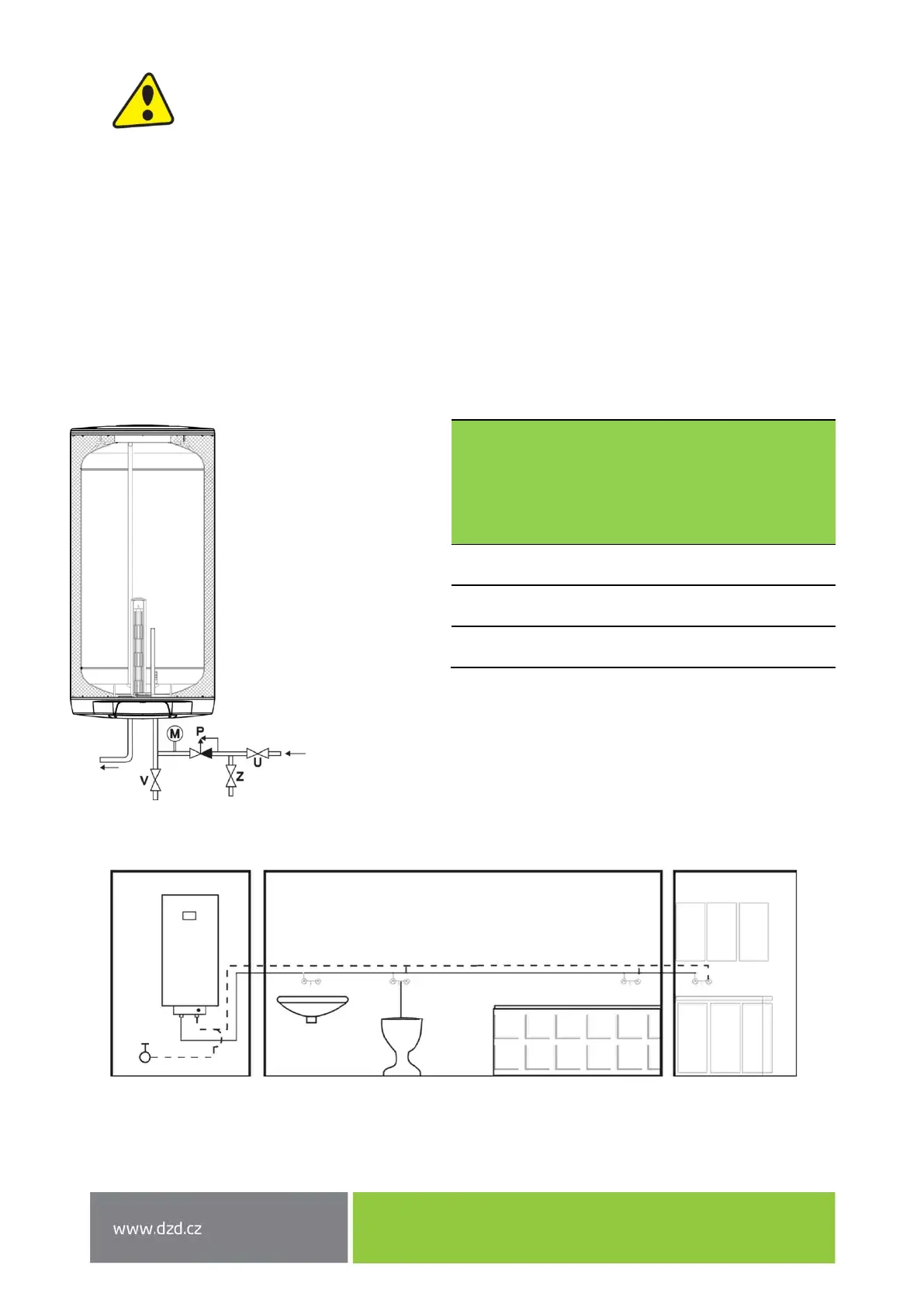

_________ Hot water

- - - - - - - - Cold water

Figure 7

SAFETY VALVE

START-UP

PRESSURE

[MPa]

OPERATING

OVERPRESSUR

E OF WATER

HEATER [MPa]

MAXIMUM

PRESSURE IN

COLD WATER

PIPES [MPa]

Water

heater

U - Closure

P - Safety valve with

backflow flap

M - Manometer

Z - Test valve

V - Drain valve

Loading...

Loading...