- 10 -

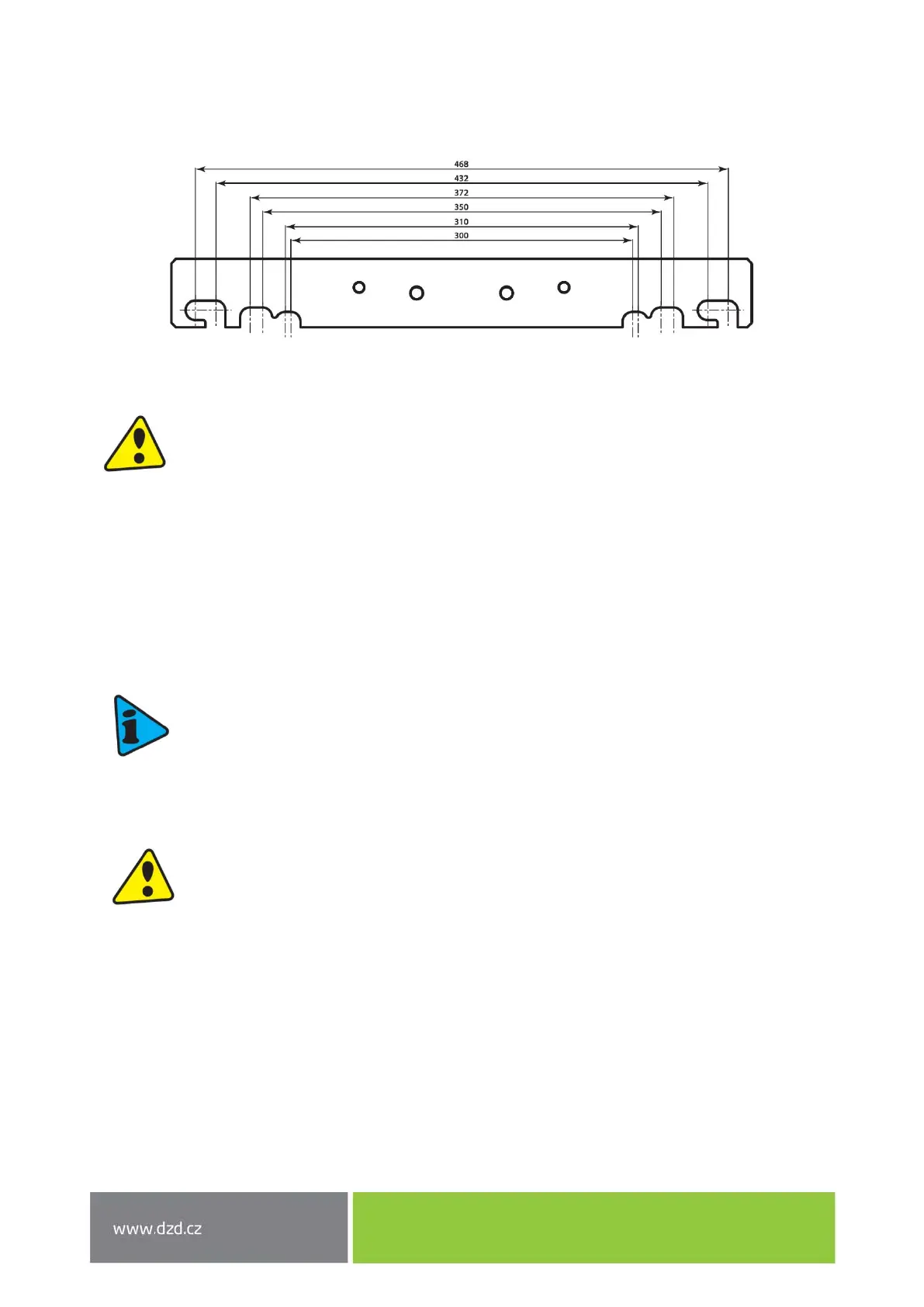

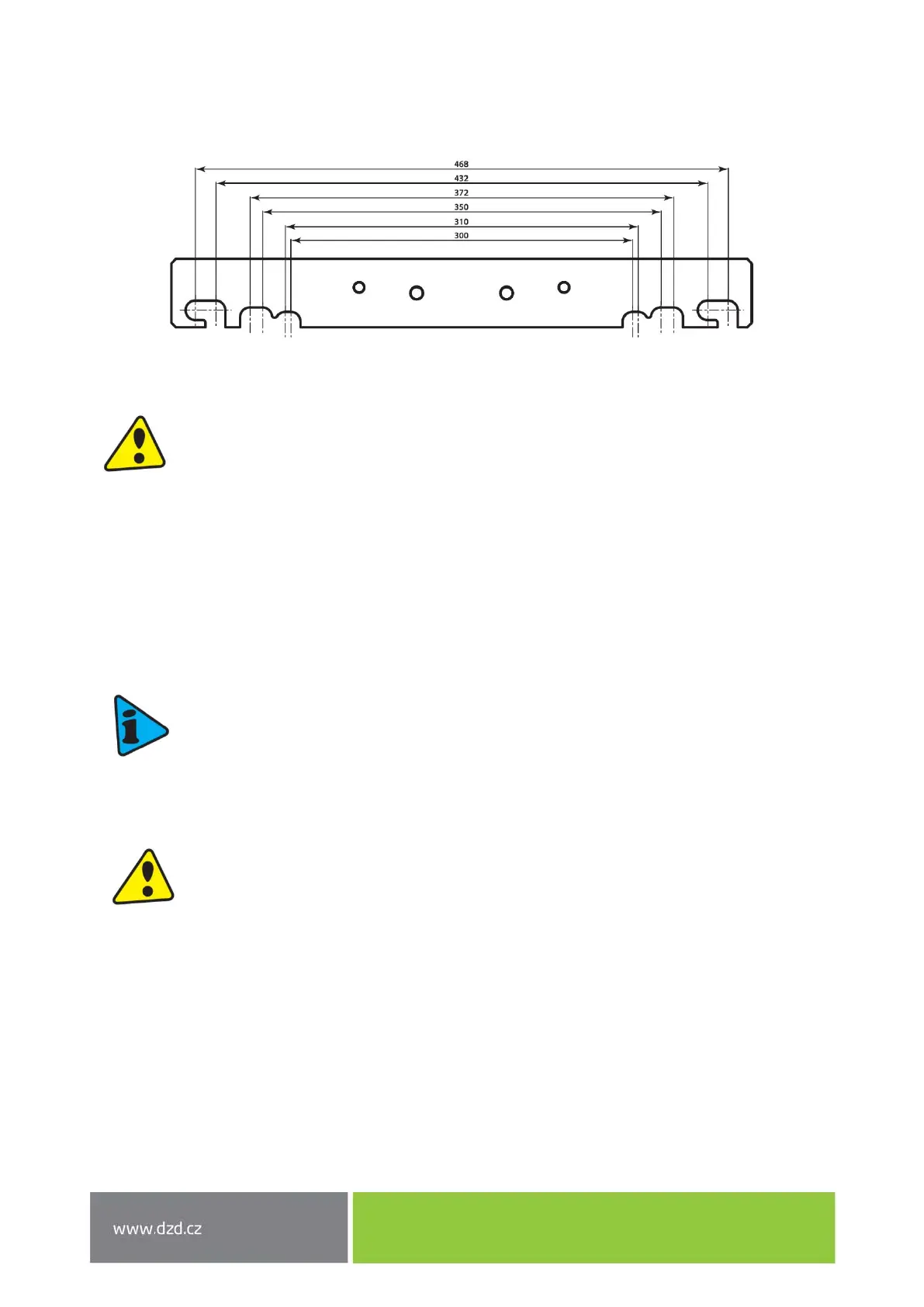

Universal suspension

The use of the suspension even for the screw spacing during the replacement with a heater of another type.

The heater verticality after the release of the connecting screws can be aligned by means of slight turning.

Figure 5

If the hot water heater is mounted in a tight, small space, or in an intermediate ceiling, etc.,

you have to make sure that the connecting side of the appliance (connections to water supply,

area for electric plugging) remained accessible and no heat accumulation occurs.

Free space of up to 500 mm from the bottom edge of the heater has to be available under the

heater.

When mounted directly under the ceiling, the distance from the ceiling has to be

50 mm at least.

If the water heater is mounted in enclosed areas, inter-ceilings, built-in structures

and recesses, ensure sufficient access to service fittings, electrical terminal boards, anodes and

manholes.

Minimum spacing from manhole is 600 mm.

2.3 PLUMBING FIXTURE

Power water connects to pipes with ¾“ thread in the bottom part of the heater. Blue - cold

water supply, red – hot water outlet. For potential disconnection of the heater, the service

water inlets and outlets must be provided with screw coupling Js 3/4“. The safety valve is

mounted on the cold water inlet identified with a blue ring.

Each hot service water pressure heater must have a safety valve with a membrane spring.

Nominal clearance of safety valves is defined by standard. Heaters are not equipped

with a safety valve. The safety valve must be easily accessible, as close to the heater

as possible. The inlet pipes must have at least the same clearance as the safety valve. Safety

valve is placed high enough to secure dripping water drain by gravity. We recommend

mounting the safety valve onto a branch pipe. This allows easier exchange without having

to drain the water from the heater. Safety valves with fixed pressure settings from the

manufacturer are used for the assembly. Starting pressure of a safety valve must be identical

to the maximum allowed heater pressure, and at least 20 % higher than the maximum

pressure in the water main (

Table 4). If the water main pressure exceeds such value,

a reduction valve must be added to the system. No stop valves can be put between the heater

and the safety valve. During assembly, follow the guide provided by the safety equipment

manufacturer. The cold water inlet of each individually closable heater must be fitted with

a seal, test tap or plug to check the non-return valve, as well as a non-return valve and safety

valve. Heaters with a volume of more than 200 litres must also be fitted with a pressure gauge.

Loading...

Loading...