b

. Look at rectangles A, B, and C to determine which offset has the best layer adhesion. Follow the instructions

below for each scenario.

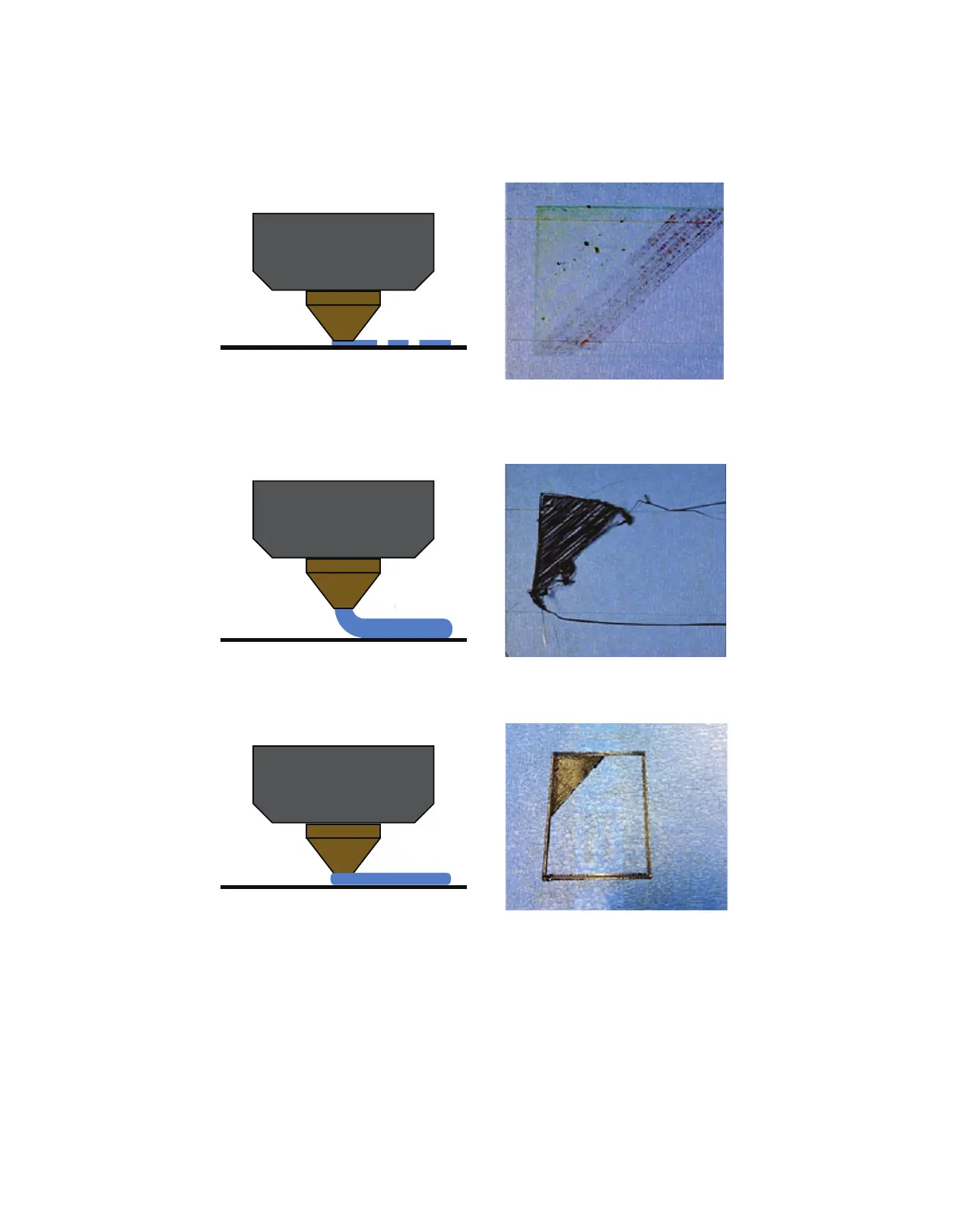

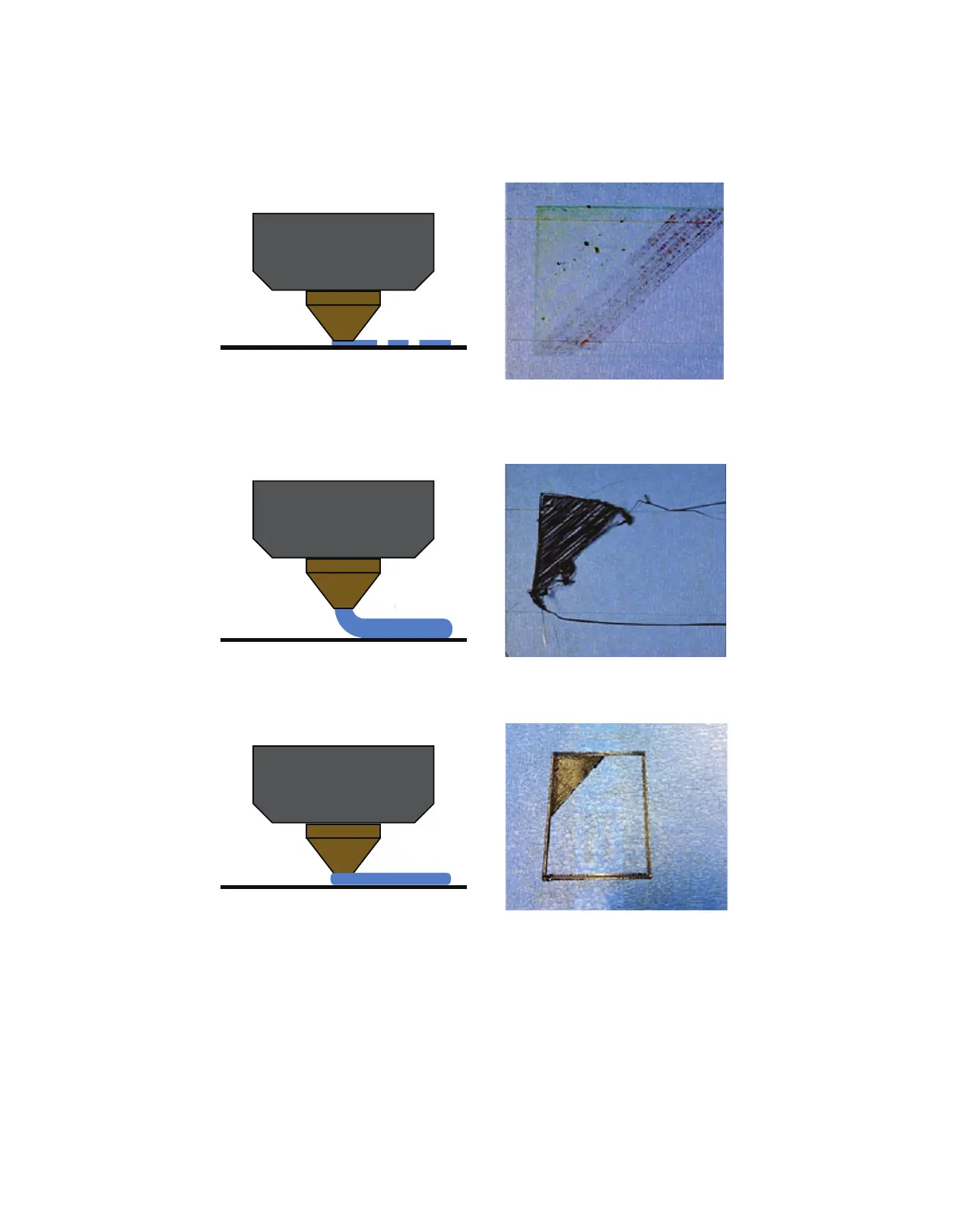

• If you see little or no filament: If the nozzle is too close to the build platform, the first layer will print too

t

ight to the build plate. Increase the Nozzle Gap +0.1mm. Repeat the Assisted Nozzle Calibration Process

until an optimum nozzle gap has been achieved.

• If the first layer is not adhering or gaps between the lines: If the nozzle is too far from the build plate, the

first layer will not adhere well. Decrease the Nozzle Gap -0.1mm. Repeat the Assisted Nozzle Calibration

Process until an optimum nozzle gap has been achieved.

• Ideal nozzle gap distance: First layer will be adhering and be visible. Lines should not look like they were

pressed against the build platform.

Congratulations!

You are now ready to build. Build On.

Loading...

Loading...