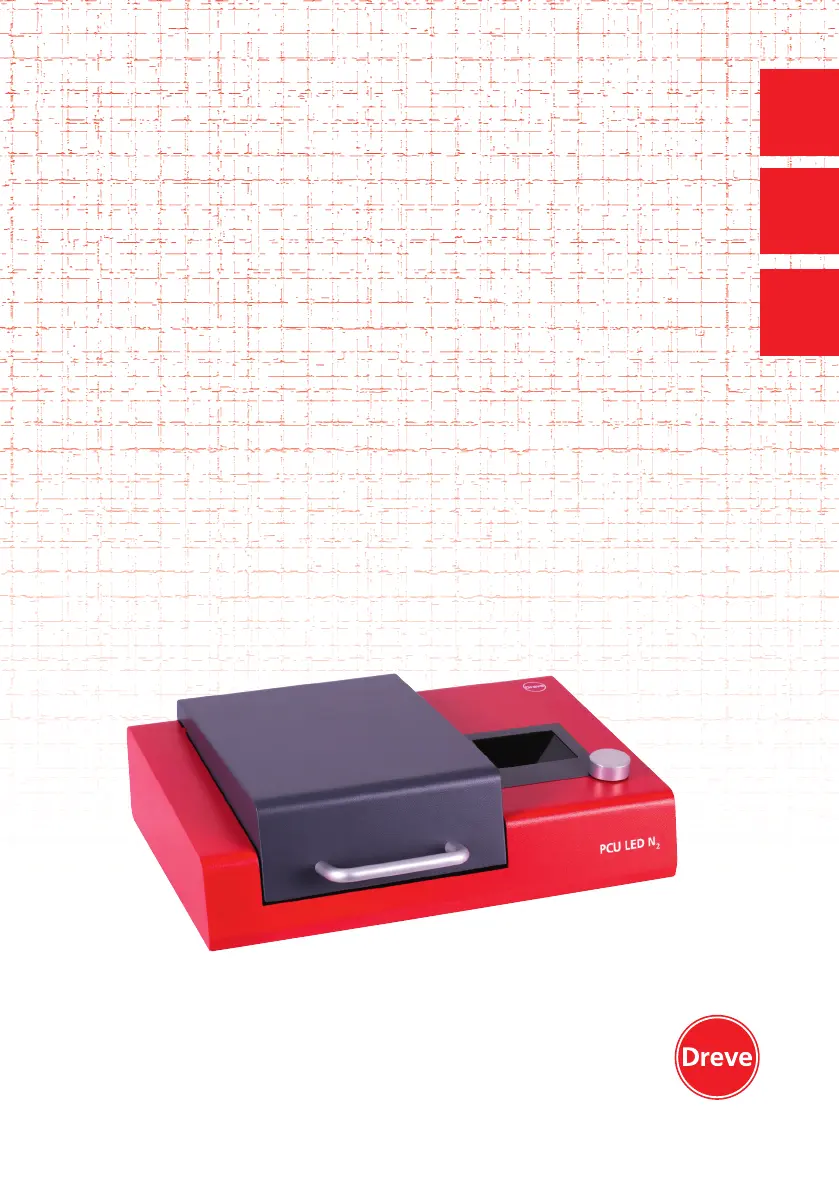

What to do if my Dreve Laboratory Equipment does not show any function?

- NNichole OwensAug 13, 2025

If your Dreve Laboratory Equipment isn't functioning, check the network connection and ensure it is correctly set up. Also, verify that the main switch is turned on. If the issue persists, the main switch might be defective and require replacement.