4

www.DrillDoctor.com

Identifying Basic Drill Bits

The Drill Doctor

®

is most efficient when used to sharpen a drill

bit’s original point angle. With its standard diamond sharpening

wheel it will sharpen high-speed steel, cobalt, TiN-coated,

carbide and masonry drill bits.

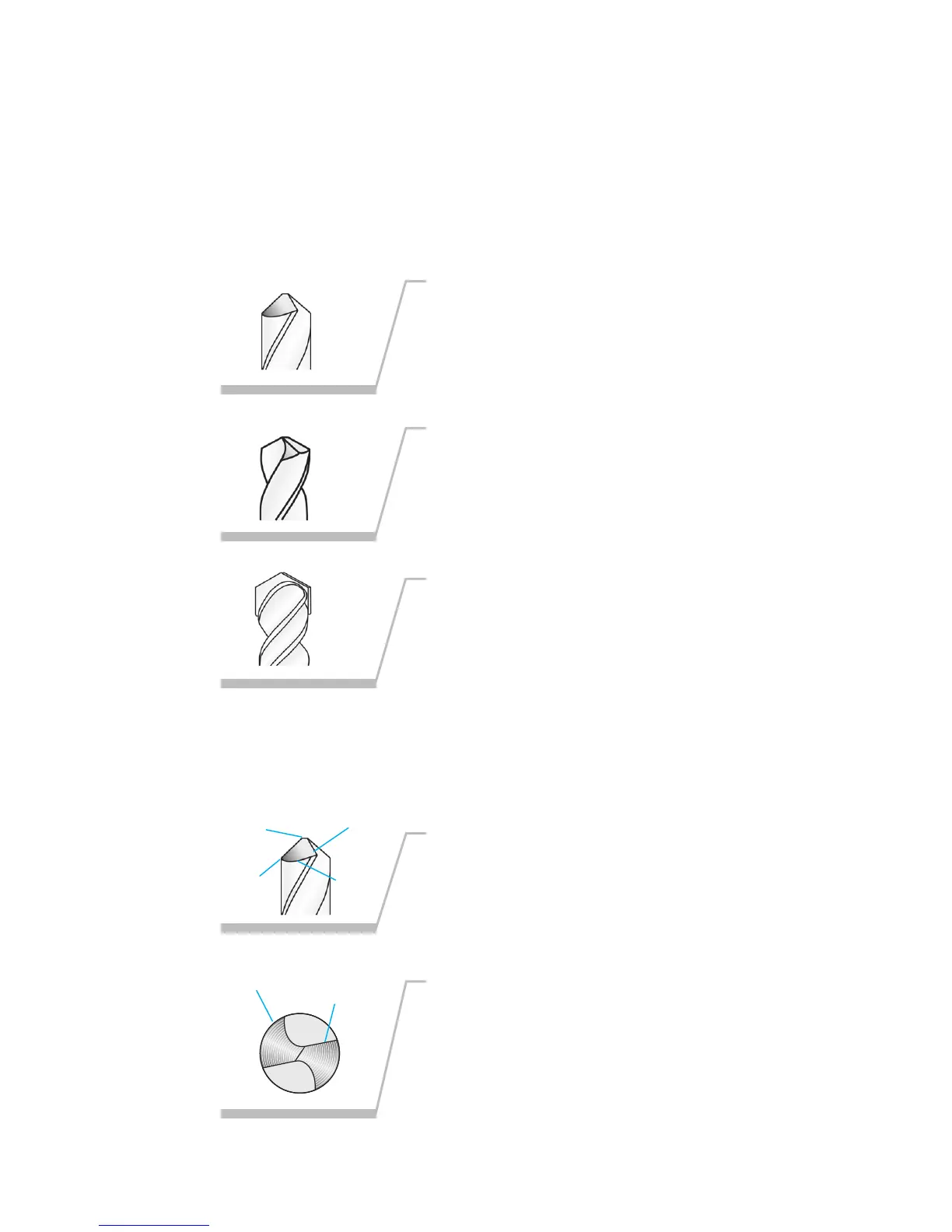

It has been designed and engineered to sharpen three of the

most common drill bit types:

Standard Point

This general purpose point (normally

118°) is used for drilling softer

materials like cold rolled steel,

aluminum, and wood.

Masonry bits (normally 135°) have

a carbide insert at the point and are

used for drilling materials like cement,

brick, and ceramic.

Split point bits (normally 135+°)

are self-centering and are generally

used for tempered steels, hard alloys

or hard cast materials.

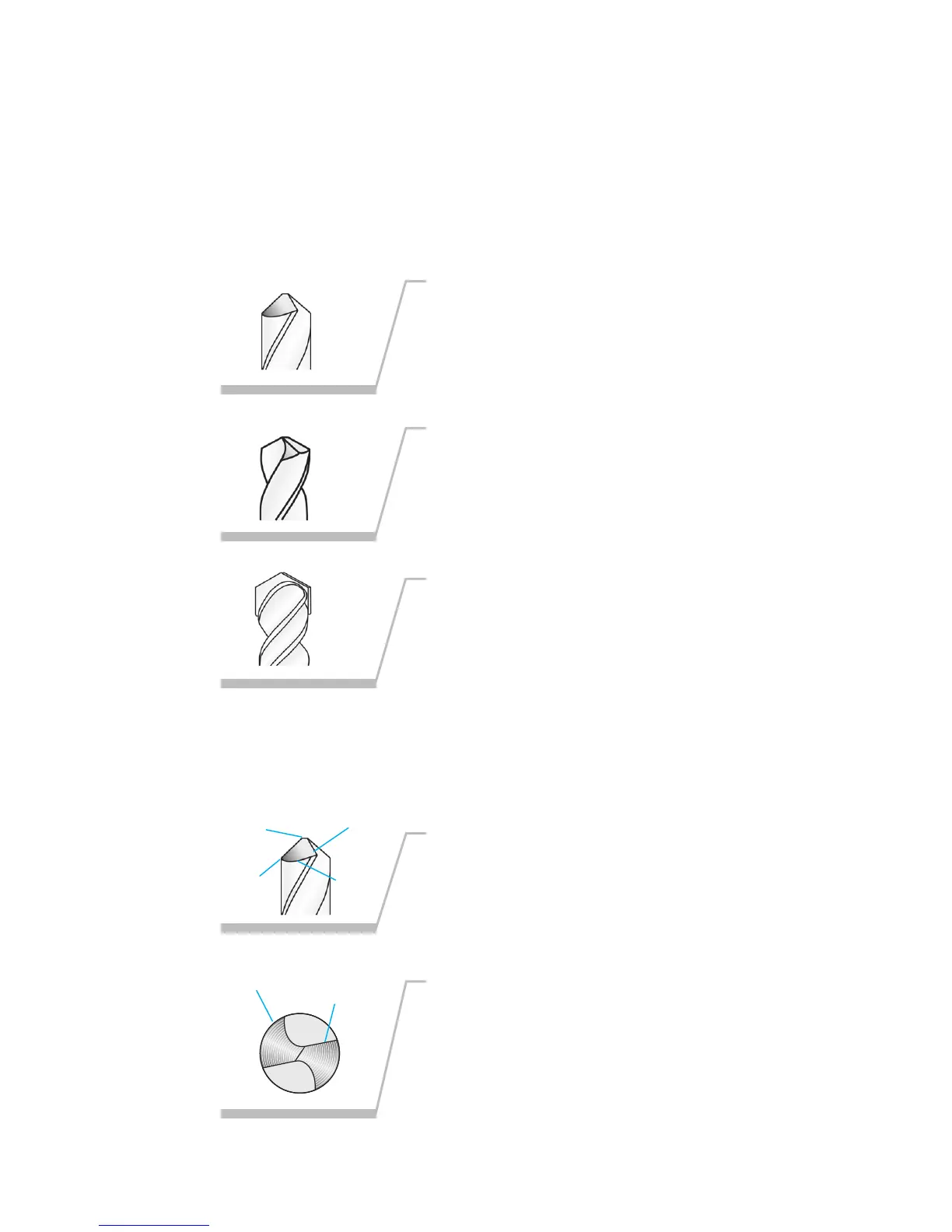

Anatomy of a Drill Bit

It is important to understand that

each bit has a Chisel Edge, a Cutting

Edge, a Heel, and a Relief Angle.

When viewing a well sharpened bit

from the end, the entire surface from

the Cutting Edge to the Heel will have

a finely ground surface without ridges

or indentations. The Heel will always be

lower than the Cutting Edge.

Heel

Chisel

Edge

Cutting

Edge

Heel

Cutting

Edge

Relief

Angle

Loading...

Loading...