18

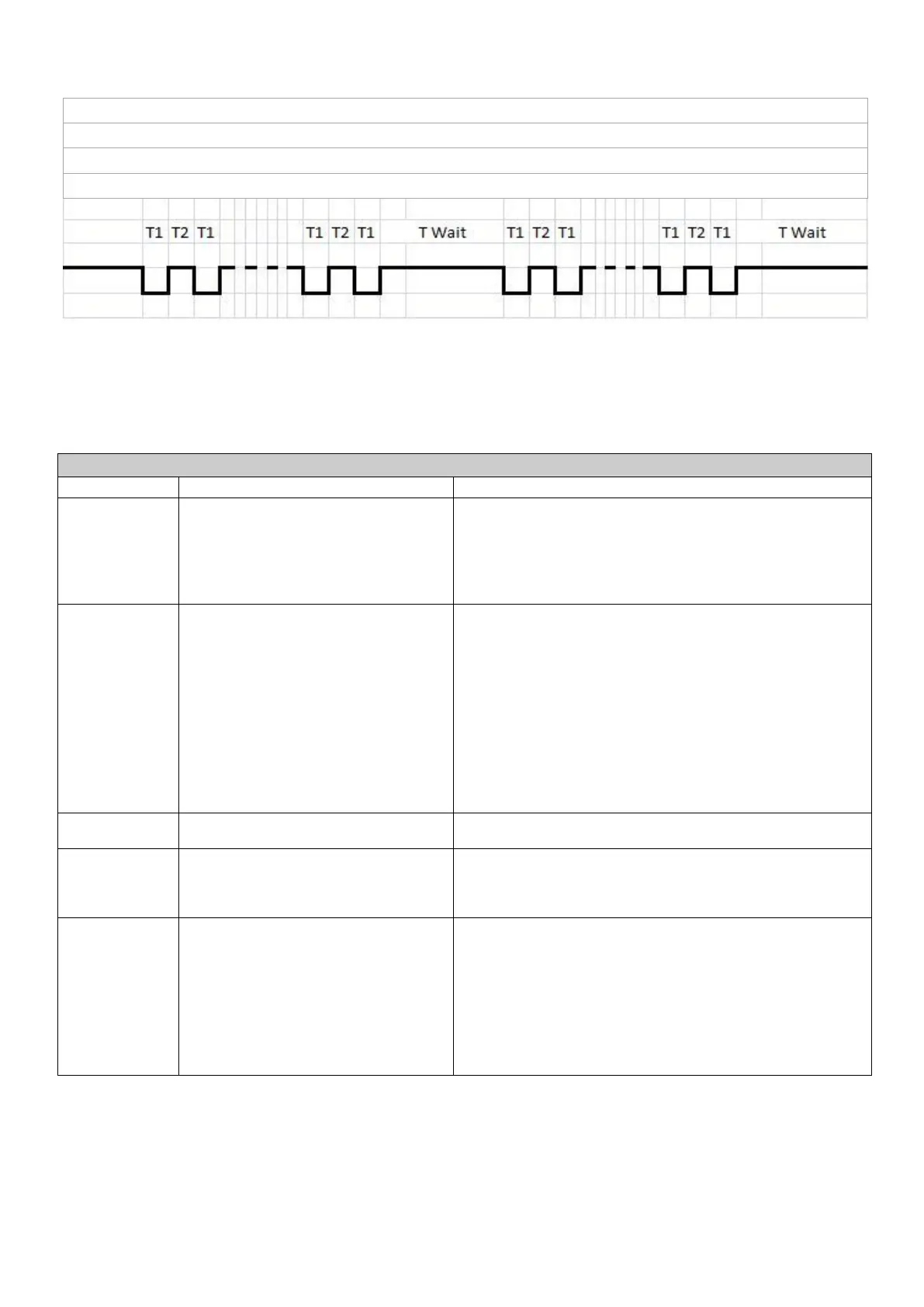

The timing chart below shows how to interface the logic with your PLC.

9.3 DIAGNOSTICS

A diagnostics table is provided below that indicates the main anomalies, the probable causes and the possible solutions.

If you were not able to solve the problem after consulting the diagnostics table, do not try to find the fault by disassembling

machine parts but contact the Dropsa technical office and report the anomalies that have been discovered, with a detailed

description.

The pump does

not deliver oil

It intakes air because the tank is empty

The intake filter is dirty or clogged

The internal fittings are loose or broken

The motor rotates backward

Restore the level in the tank and bleed the air from the system

Wash the filter with petroleum and blow with compressed air

Carefully close all the fittings, making sure there are no leaks and

replace the broken pipes.

Correctly connect the motor, inverting the direction of rotation

The pump does

not deliver oil at

the required

pressure

Pump deteriorated

Pressure control valve uncalibrated set too

low (therefore the oil returns immediately

to the tank).

Release valve damaged

Adjustment valve incorrectly calibrated

Presence of dirt in the by-pass valve

Replace the pump

Tighten the adjustment screw until oil comes out of the delivery pipe

Replace the by-pass valve

Connect a pipe that is approx. 30 cm long to the pump outlet with a

pressure gauge applied to the free end. Adjust the valve by turning

the screw and reading the corresponding pressure value on the

pressure gauge

Remove the components and wash them with petroleum. Before

reassembling the components, check the wear status of the O-ring.

Replace the entire assembly if necessary

Line pressure not

released

Control valve with irregular operation

Disassemble and clean the by-pass valve, replace the valve if

necessary

Emptying of the

main system line

during the pause

time

Pump or system outlet fittings loosened

Non-return or release valve dirty

Tighten the fittings

Disassemble and clean the by-pass valve, replace the valve if

necessary

Lubrication cycle

not performed

Cycle control pressure switch calibration

pressure not reached due to:

Line pipe broken or loose fittings

Pressure switch calibrated higher than the

pump

The pump does not deliver oil at the

required pressure

The pump does not deliver oil

Replace the pipe - fully tighten the fittings

Correctly calibrate the pressure switch

See the diagnostics table

See the diagnostics table

Alarm code= number of (T1+T2)

T1= 500ms = alarm contact activation time

T2= 500ms = alarm contact deactivation time

TWait= 2000ms= pause time before repetition of same alarm code

Loading...

Loading...