pressure to build up. Run a temporary connection

from one of the drain valves to a nearby sewer.

Connect to a drain valve on the opposite end of the

boiler from feed water inlet, if possible. Shut off the

oil burner, open drain valve and blow down the entire

contents of boiler.

Allow boiler to thoroughly cool and slowly refill to water

line. Repeat as many times as required until blow off

water is clear. Owner should blow down boiler at least

once each month d the heating season.

If an exceptional amount of dirt or sludge seems to

be present in the boiler, a boiler cleaning compound

made by a reputable manufacturer may be used

according to the instructions of the manufacturer of

the compound. When any type of cleaning com-

pound is used, care must be taken to thoroughly

flush all traces of the compound out of the boiler.

Following blow down allow the boiler to coot. Add

fresh water slowly. Be certain to blow enough times

as required to remove compounds from system.

The area around the boiler must be kept clear and

free of combustible materials, gasoline and other

flammable vapors and liquids.

The free flow of combustion and ventilation air to the

boiler and boiler room must not be restricted or

blocked.

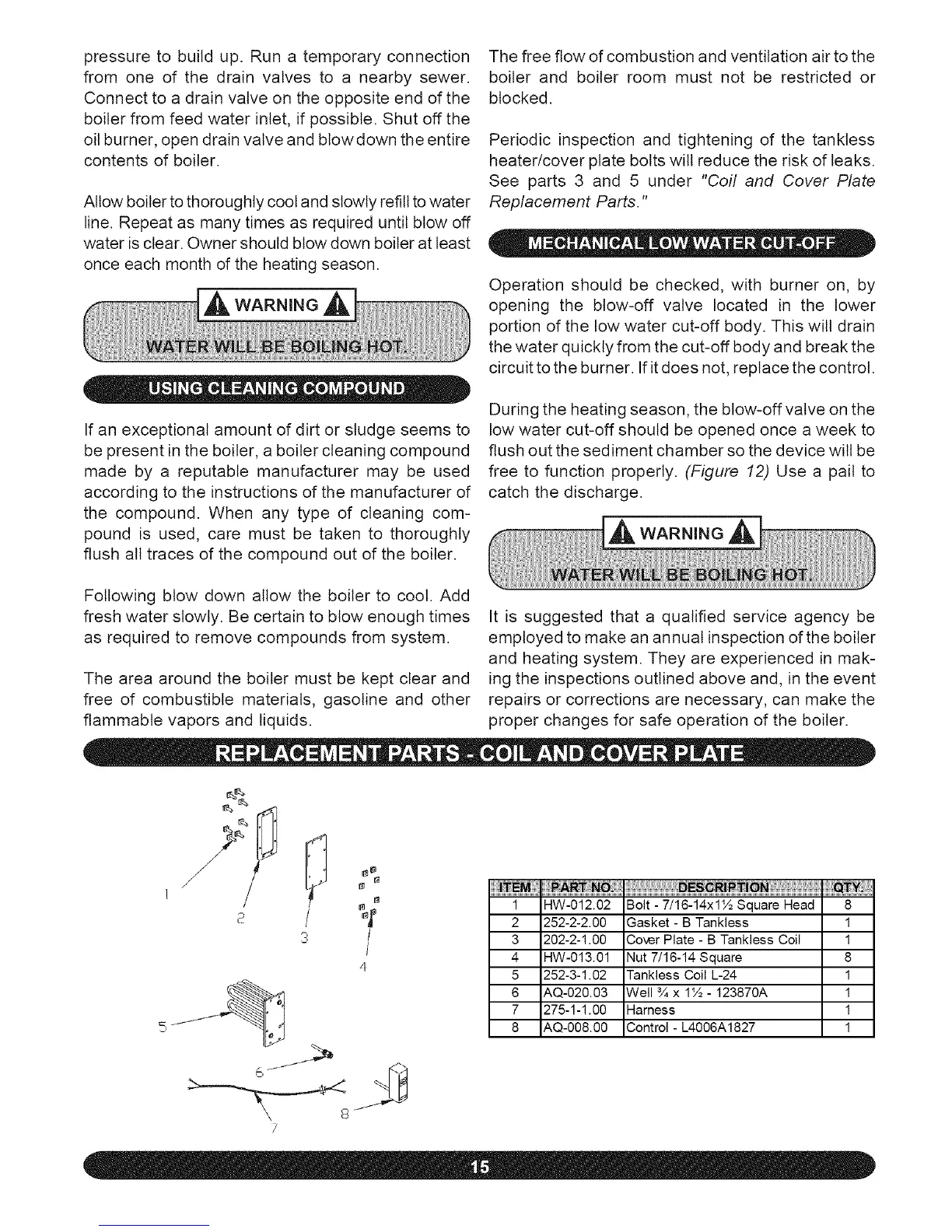

Periodic inspection and tightening of the tanktess

heater/cover plate bolts will reduce the risk of leaks.

See parts 3 and 5 under "Coil and Cover Plate

Replacement Parts."

Operation should be checked, with burner on, by

opening the blow-off valve located in the lower

portion of the low water cut-off body. This will drain

the water quickly from the cut-off body and break the

circuit to the burner. If it does not, replace the control.

During the heating season, the blow-off valve on the

low water cut-off should be opened once a week to

flush out the sediment chamber so the device will be

free to function properly. (Figure 12) Use a pail to

catch the discharge.

It is suggested that a qualified service agency be

employed to make an annual inspection of the boiler

and heating system. They are experienced in mak-

ing the inspections outlined above and, in the event

repairs or corrections are necessary, can make the

proper changes for safe operation of the boiler.

\

\

/

1 HW-012.02 Bolt - 7/16-14x1½ Square Head 8

2 252-2-2.00 Gasket - B Tankless 1

3 202-2-1.00 Cowr Plate - B Tankless Coil 1

4 HW-013.01 Nut 7/16-14 Square 8

5 252-3-1.02 Tankless Coil L-24 1

6 &Q-020.03 Well ¾ x 1½ - 123870A 1

7 275-1-1.00 Harness 1

8 &Q-008.00 Control - L4006A1827 1

Loading...

Loading...