Common Compressor Faults

Common Faults.

Noted below are the most common Faults experienced.

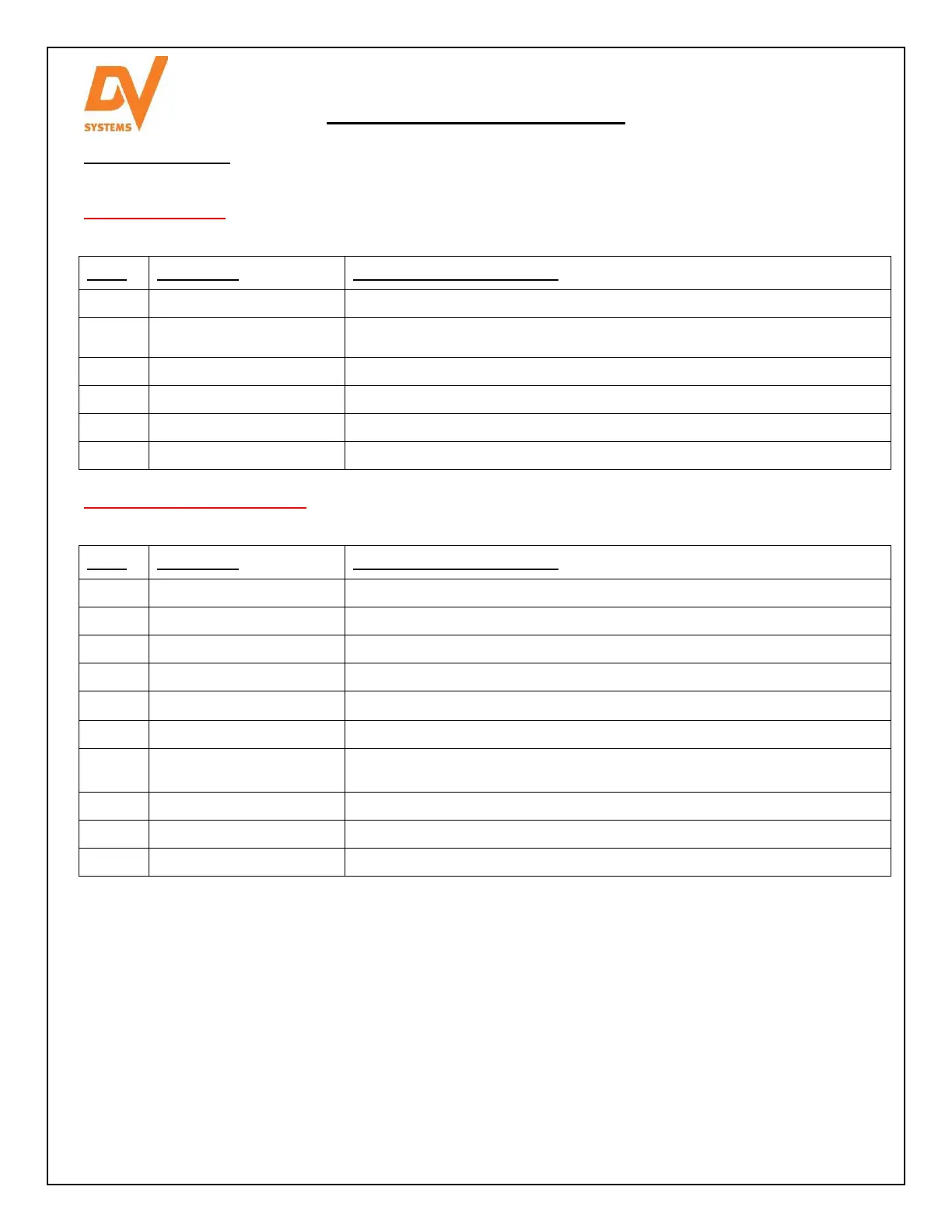

‘CSC300’ Alarms.

There is an issue with the Unit, but it will still operate.

Most Common Items to Check:

Check supply voltage, fuses and cable

Solenoid not working, Intake Valve Orifice clogged, Transducer dirty or faulty, pressure changed

incorrectly, alternate external pressure source

Delivery Temperature High

Ambient temp high, Unit dirty, low oil level, no air flow through Unit, Temp Sensor defective

Press ‘Reset’ Button and restart Unit

Service Unit and reset Service Timer (Page ‘P16’ on Controller)

Service motor and reset Grease Service Timer (Page ‘P16’ on Controller)

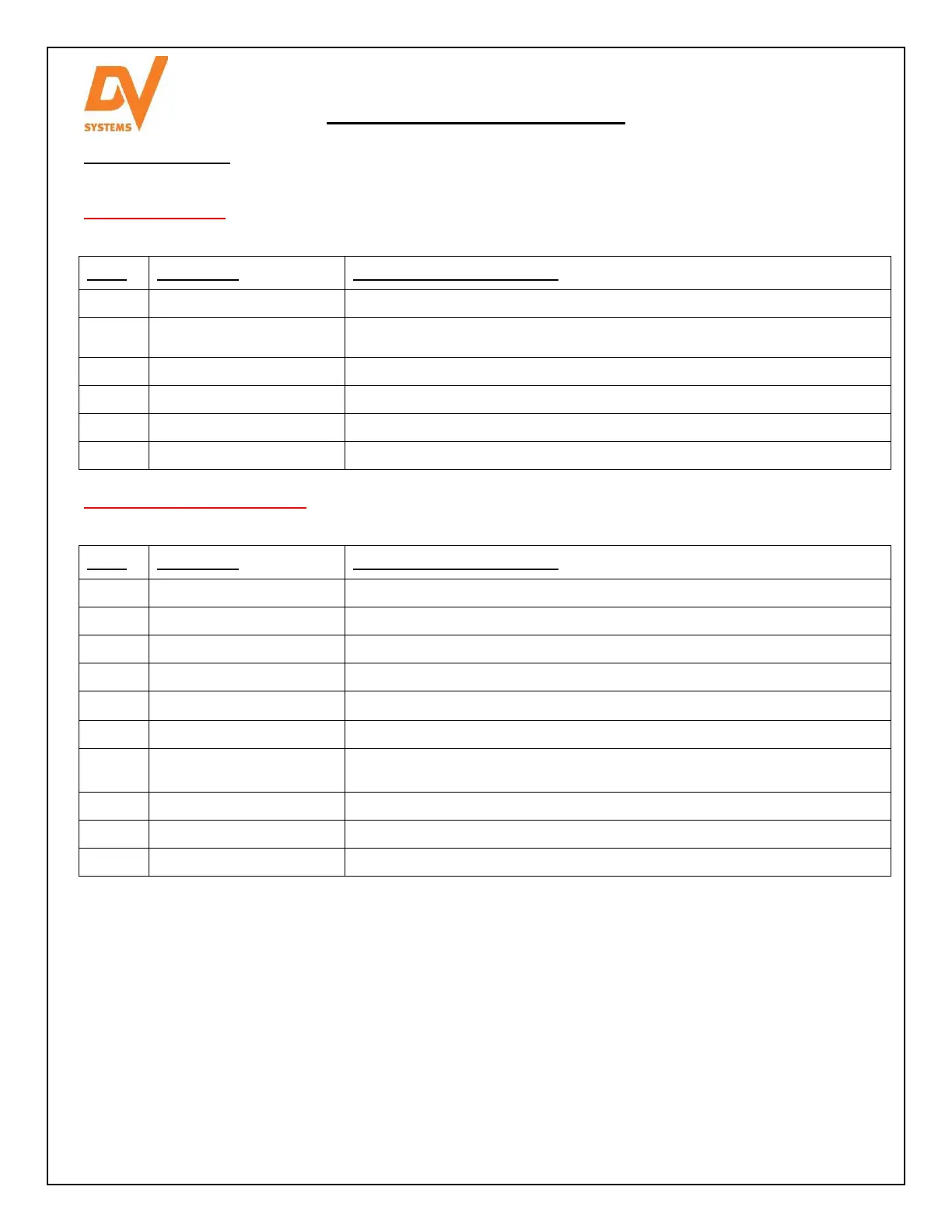

‘CSC300’ Shutdown Errors.

There is an issue with the Unit, and the Unit will not operate until the Fault has been addressed.

Most Common Items to Check:

Emergency stop switch is pressed

Motor drawing high amps, low voltage, high pressure settings, low oil level

Check motor connections in the control panel and motor connection box

Rotation of Motor wrong, sequence order of supply cable incorrect

Check supply voltage, fuses and cable

Delivery Pressure Sensor Fault

Transducer not making good electrical contact, or defective

Solenoid Not working, Intake Valve Orifice clogged, Transducer dirty or faulty, pressure

changed incorrectly, alternate external pressure source

Delivery Temp Sensor Fault

Temperature Sensor not making good electrical contact, or defective

Delivery Temperature High

Ambient temp high, Unit dirty, low oil level, no air flow through Unit, Temp Sensor defective

Rotation of Main Motor wrong, Solenoid Valve not relieving pressure

Loading...

Loading...