D20, D20VSD, D20TD, D20TDVSD-C

Feb ‘14

- 12

AC Motor Maintenance Instructions

Cleaning.

To ensure that the Motor operates at optimum temperatures and provides years of trouble-free service,

periodically clean the outside of the Motor Housing of any build-up of dust, etc. Though it is not anticipated that, if

installed correctly and in a suitable environment, there should be much build-up on the Motor, keeping the

Housing clean will allow the Motor to operate more efficiently.

Lubrication.

This is a ball bearing motor. The bearings have been lubricated at the factory. Motors that do not have re-grease

capability are factory lubricated for the normal life of the bearings.

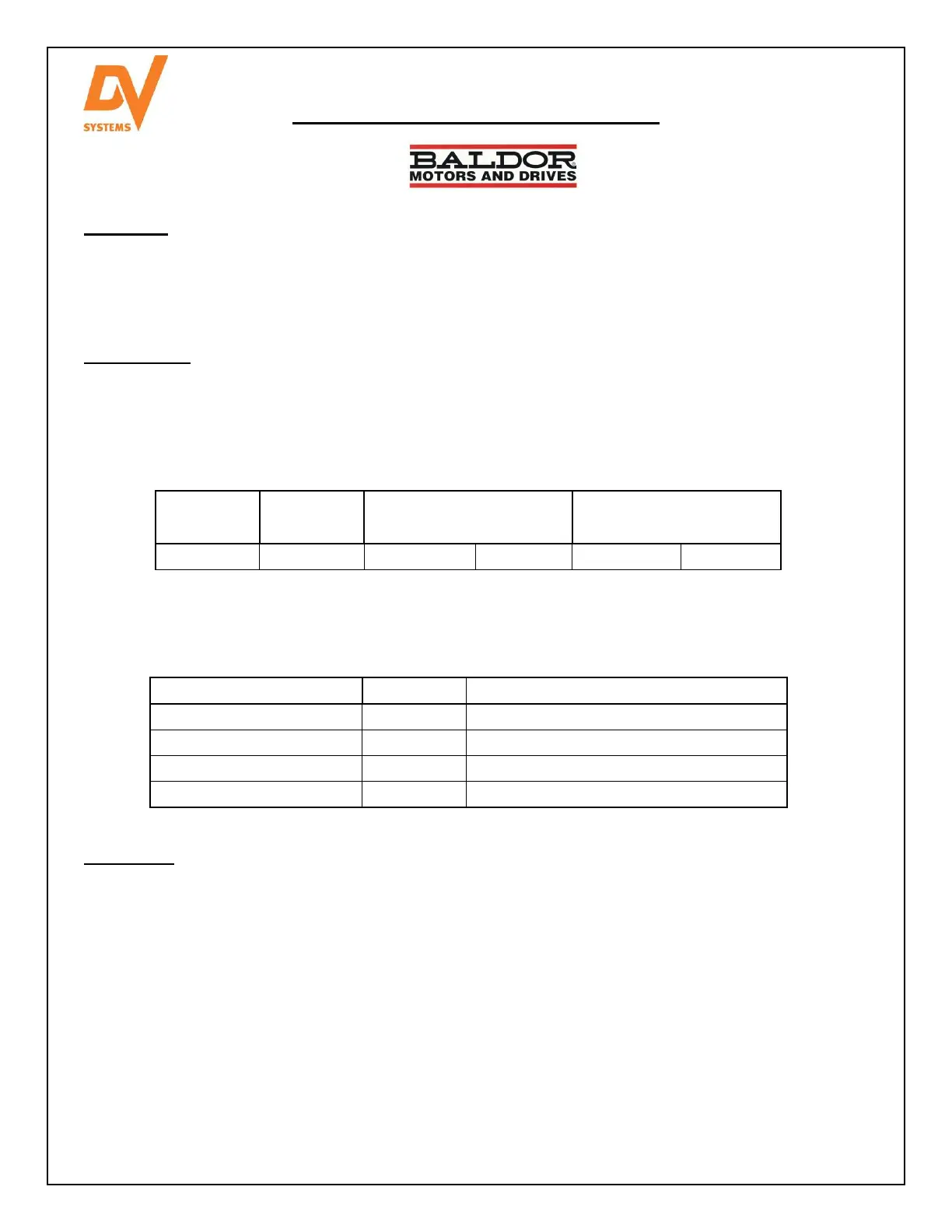

Noted below is a chart outlining the interval at which the Motor should be lubricated, this based on the Motor

horsepower. This must be part of a regular maintenance schedule.

Motor HP

Interval Weight of Grease Volume of Grease

in Hours Ounces Grams Cubic Inch Teaspoon

20 2,000 0.81 23.1 1.5 5.2

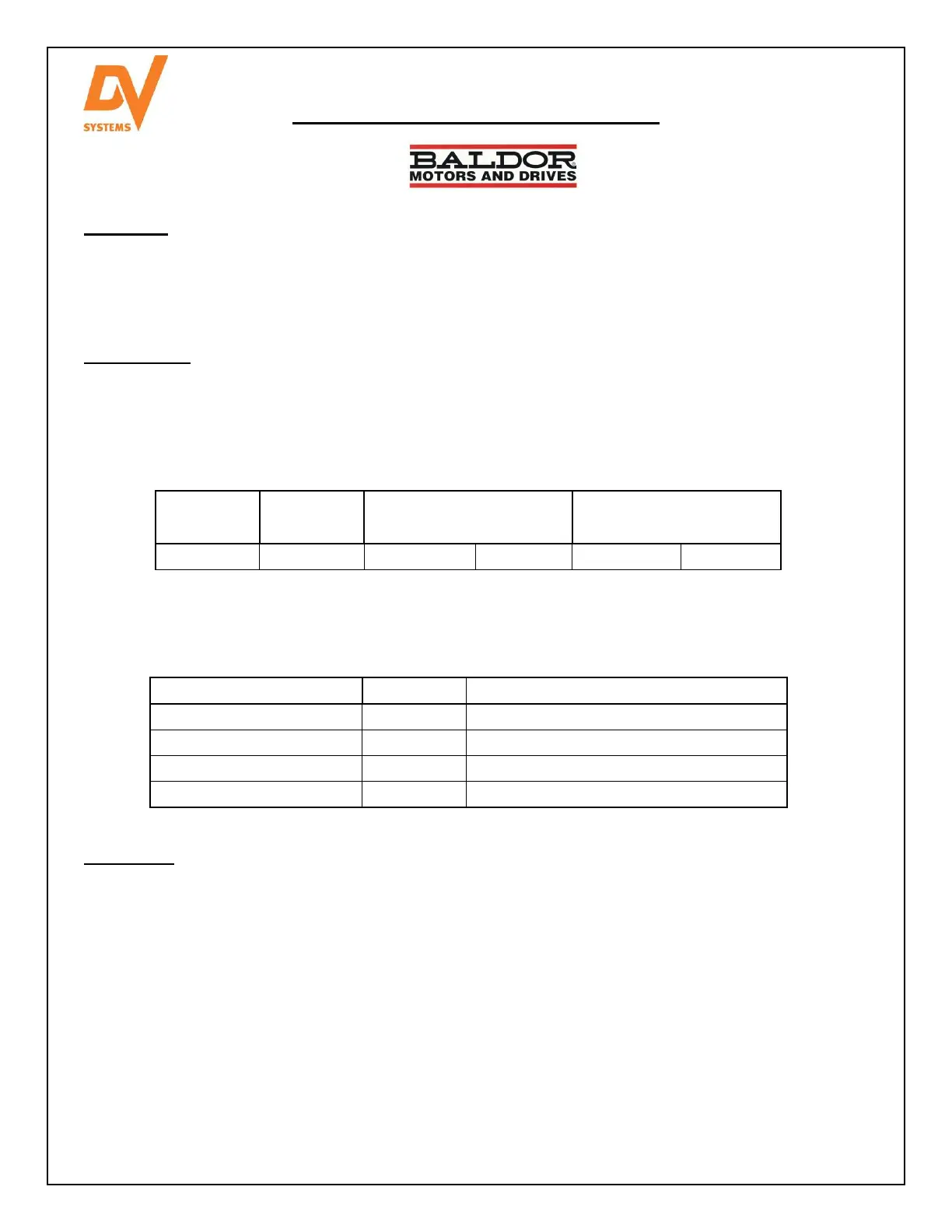

The above chart is based on a standard environment in which the Motor is operating of 40°C. For other

conditions, please multiply the Hour Interval from the chart above by the factor as indicated below.

Severity of Duty Factor Environmental Conditions

Standard 1.0 40°C, clean, little corrosion

Severe 0.5 50°C, moderate dirt, corrosion

Extreme 0.1 > 50°C, severe dirt, abrasive dust

Low Temperature 1.0 < 30°C

Lubricant.

Baldor motors are pre-greased, normally with Chevron SR #2. Equivalent and compatible greases are Texaco

Polystar, Shell Dolium R and Amoco Rykon Premium #2.

Loading...

Loading...