D20, D20VSD, D20TD, D20TDVSD-C

Feb ‘14

- 15

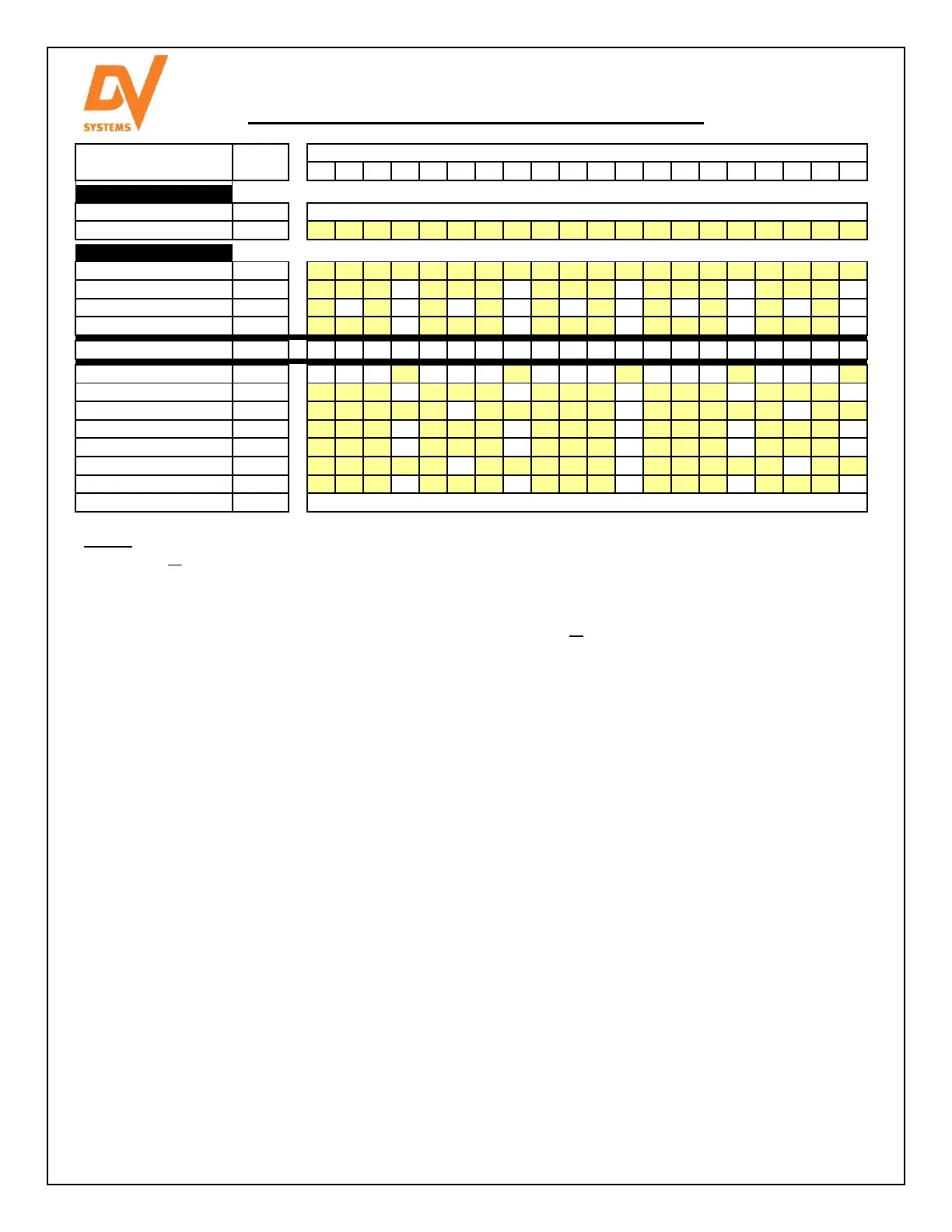

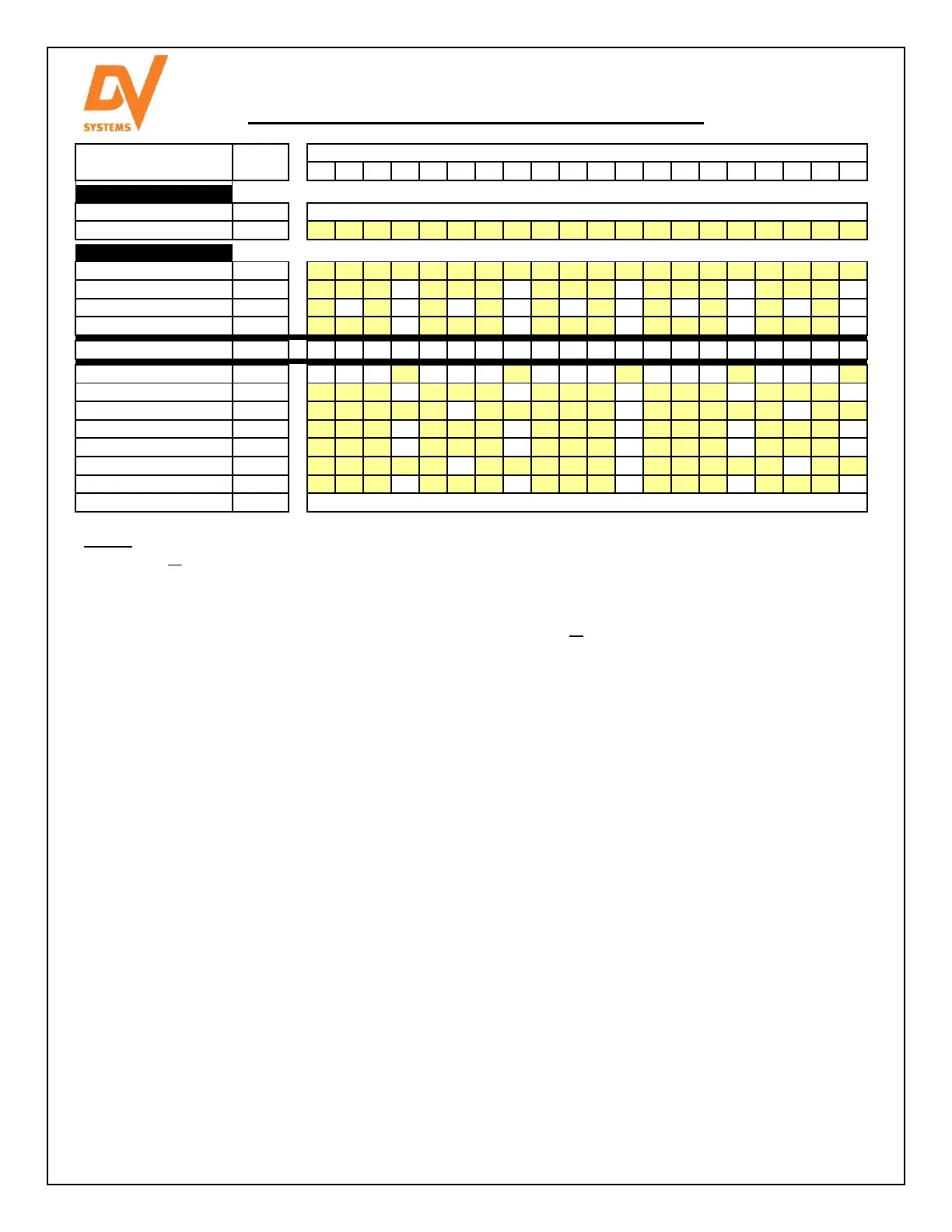

Preventative Maintenance Schedule (cont’d)

Maintenance Item: Daily

Maintenance Interval (in 000’s of Hours)

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40

Compressor Room

Temperature Inspect Ambient Temperature should be between 10°C and 40°C (50°F and 104°F)

Cleanliness Inspect

Air Compressor Unit

Check Oil Level Inspect

Replace Oil # (See Note b) (1) X X X X X

Replace Oil Filter # (2) X X X X X X X X X X

Replace Air / Oil Separator # (3) X X X X X

Replace Air Intake Filter # (4) X X X X X X X X X X X X X X X X X X X X

Check Belt Tension X X X X X X X X X X X X X X X

Replace Belts X X X X X

Replace Tank Relief Valve X X X

Replace Solenoid (5) X X X X X

Rebuild Intake Valve (6) X X X X X

Rebuild Thermo Valve (7) X X X

Rebuild Minimum Pressure Valve (8) X X X X X

Motor Bearing Lubrication Refer to Motor Manufacturer’s Recommendations on Page 12

Notes: a) For Compressor Units used in an environment where the ambient temperature is above 90°F (32°C),

or b) where the Unit temperature runs regularly above 80°C (175°F), the components marked with a

‘#’ must be changed twice as often (example: in 4000 hours instead of 8000), and not as noted

above.

b) The DV Systems Oil used in the Rotary Screw Units is rated as an 8000 hour Oil. A complete Oil

change must be done every 8000 hours of Unit operation, or every 12 months, whichever occurs first.

Please refer to the Warranty on Page 26 for further information.

c) If a component, during a regular inspection, has proven to be defective or unfit for regular operation, it

must be repaired or replaced.

Parts and Repair Kits based on the above chart are as follows:

(1) Oil: 2 x DEV-3000-K1

(2) Oil Filter DSC-002197

(3) Air / Oil Separator Filter DSC-001148

(4) Air Intake Filter DSC-002196

(5) Solenoid DSC-002199

(6) Intake Valve Repair Kit DSC-002203

(7) Thermo Valve Thermostat & Sealing Ring: DSC-002201 & DSC-002608

(8) Minimum Pressure Valve Repair Kit: DSC-002202

Loading...

Loading...