INSTALLATION

1. LOCATION: Select a location where the temperature of

the unit will be between 20°F and 120°F. Distance from

the receiver is limited only by total loop resistance. See

“Electrical Connections”. The tubing feeding pressure

to the instrument can be run practically any length

required but long lengths will increase response time

slightly. Avoid surfaces with excessive vibration.

2. POSITION: All standard models are calibrated with the

diaphragm vertical and should be used in that position

for maximum accuracy. If your application requires

mounting in other than a vertical position, be sure to

specify this when ordering.

3. PRESSURE CONNECTIONS: For convenience, two

sets of 1/8˝ female NPT ports are available. Plug the

unused set with pipe plugs provided. Attach tubing

from positive pressure source to port marked “HI” or

from negative (Vacuum) source to port marked “LOW”.

In either case, opposite port must be vented to atmos-

phere. In dusty environments, we recommend use of an

A-331 Filter Vent Plug to keep interior of instrument

clean. For differential pressures the higher source is

connected to the “HI” port and lower to the ”LOW” port.

4. MOUNTING: The Series 605 Transmitter may be either

panel mounted or surface mounted.

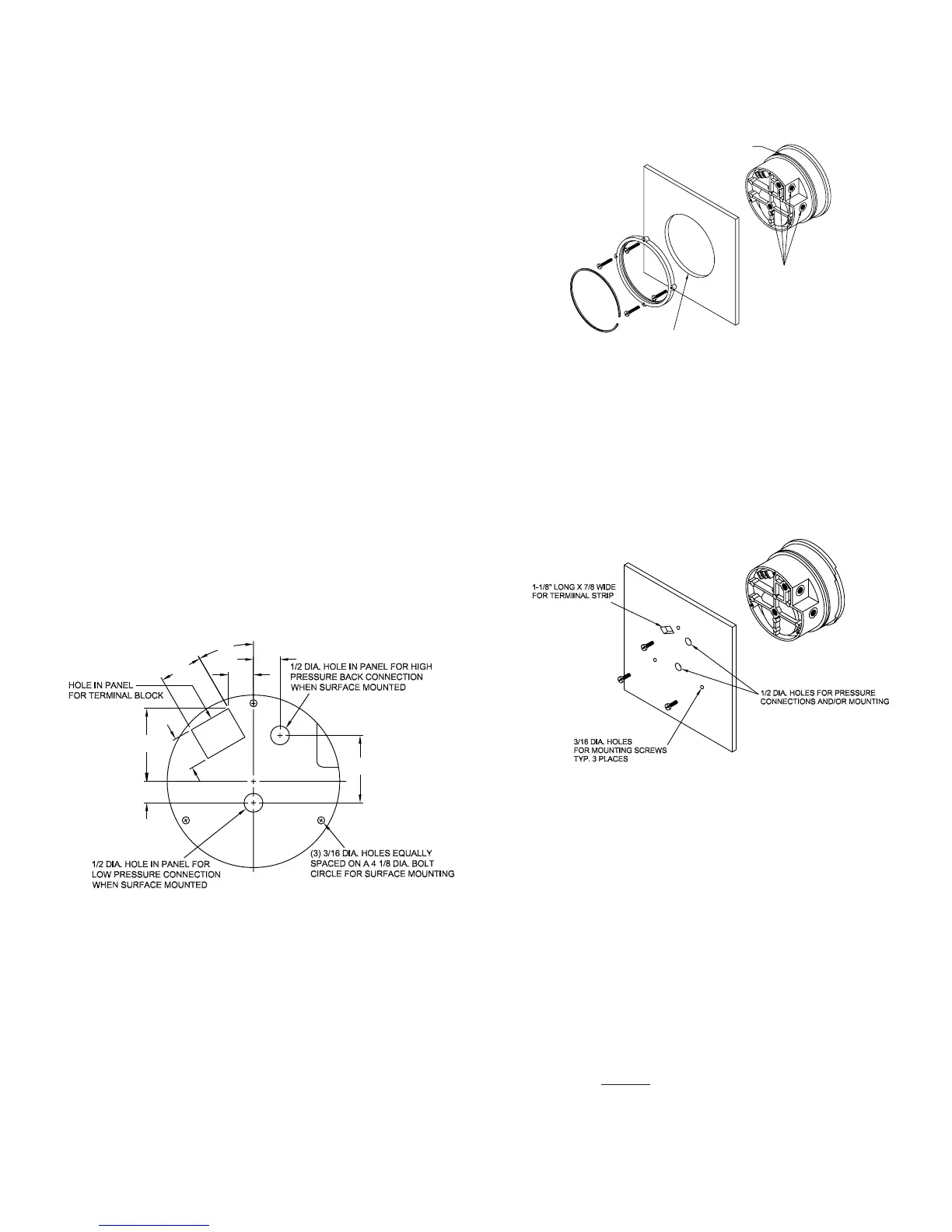

A. PANEL MOUNTING: Cut a 4-3/4˝ or 120 mm dia.

hole in panel and insert the complete unit from the

front. Slip on the mounting ring and install the split

snap ring in the groove on the bezel. Seat the mount-

ing ring against the snap ring and thread the four

screws through the tapped holes. Tighten screws

against rear of panel.

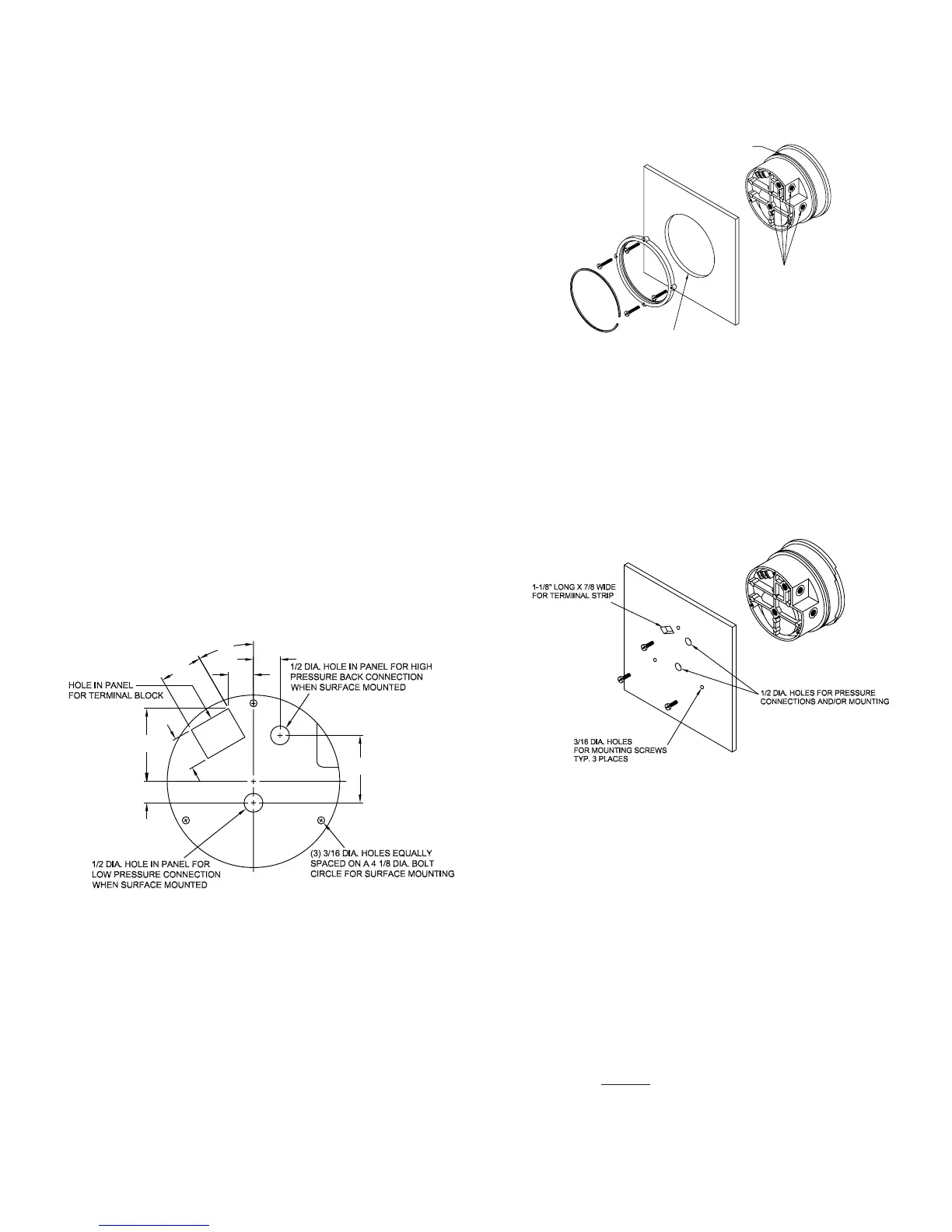

B. SURFACE MOUNTING: Drill (3) 3/16˝ dia. holes for

mounting screws and cut (1) 7/8˝ x 1-1/8˝ hole for

access to terminal strip as shown in hole location

drawing. Insert screws from rear of panel and thread

into tapped holes on back of transmitter case. If rear

pressure connections are to be used, make 1/2˝ dia.

holes located as shown in hole location drawing in left

column.

5. ZEROING: Once gage/transmitter is mounted in its

final position, check to be sure pointer aligns with zero

on scale, when no pressure is applied and both low and

high pressure ports are vented to atmosphere. To

adjust, turn small slotted screw at center-bottom of

gage face. Do not move the larger black knobs labeled

SPAN and ZERO. These are for use only if a calibration

check shows the 4-20 mA output signal to need adjust-

ment. See page 3 under heading OUTPUT RANGING.

7

17/32

1-7/8

7/8

1-1/8

30°

11/16

21/32

1-3/4

SNAP RING GROOVE

PNEUMATIC PRESSURE TAPS

4-3/4 DIA. HOLE

E-68 8/2/07 8:43 AM Page 2

Loading...

Loading...