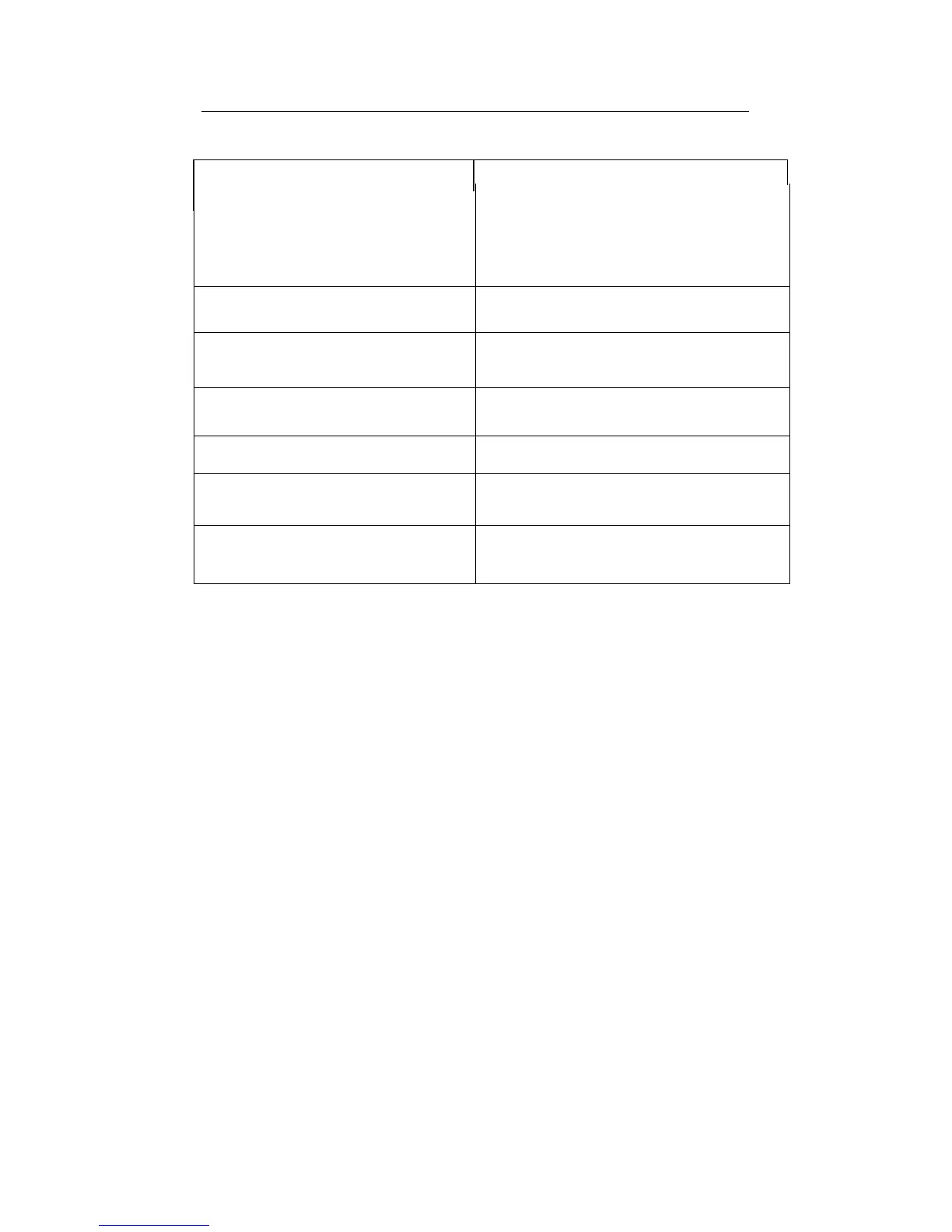

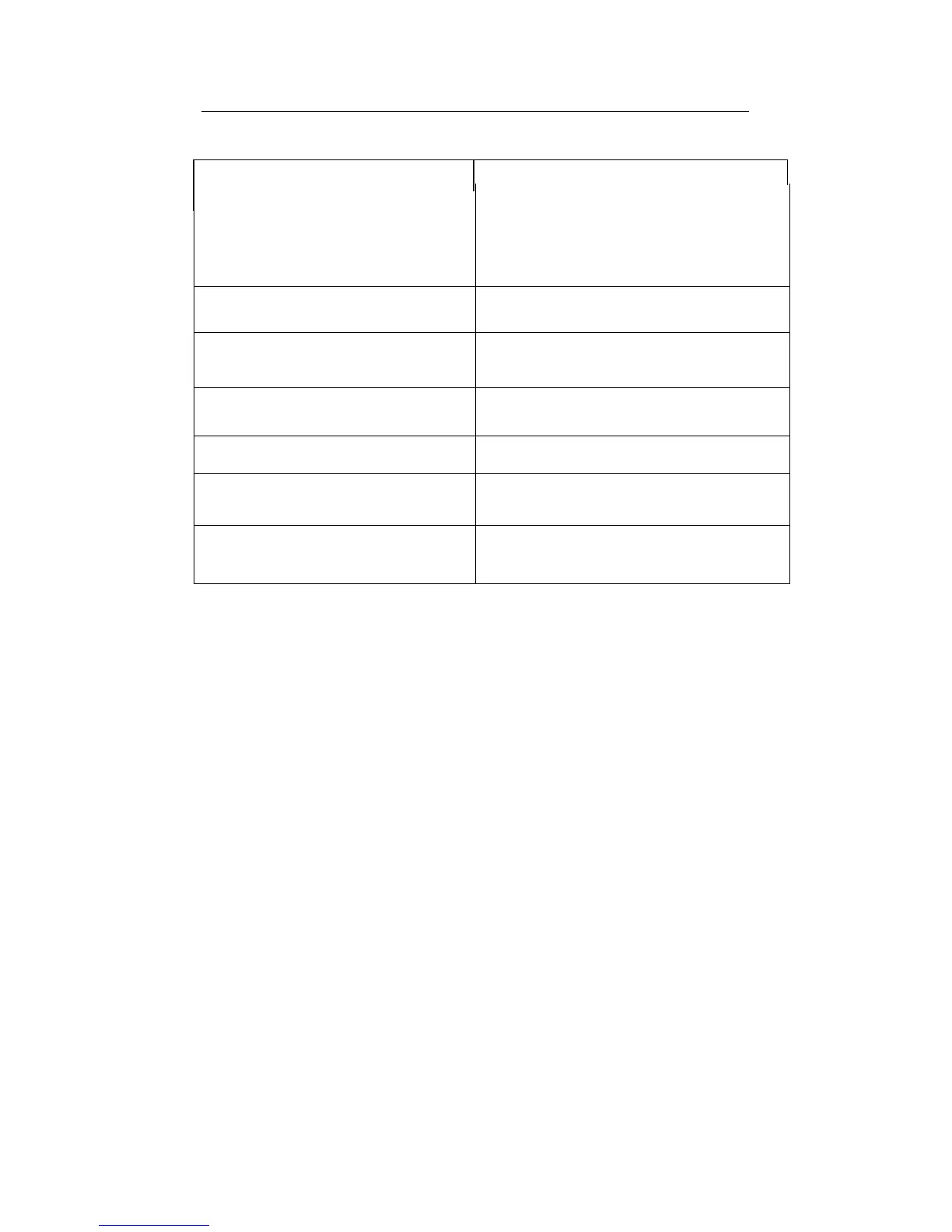

TROUBLESHOOTING

CAUSES

TROUBLESHOOTING

Tighten the nuts of cylinder head in

Deficiency in pressure of compression.

Loosened nut of cylinder head.

Damage or leakage in the gasket of

cylinder.

the diagonal sequence; check the

gasket of cylinder as per the standard 1

requirement. When the engine with

the new gasket is heating, tighten the

nut of cylinder head again.

Big gap in the piston ring due to wear

and tear

Leakage caused by each gap of

piston ring lined in one direction

Make each gap of piston at angle of

120

Serious stickiness or breakage in

piston ring

Clean it by diesel fuel or change the

piston ring.

Skive the valves, or send it to repair

factory if the vestige is too deep.

Incorrect valve clearance

Adjust the gap as specified (0.15 ~ 1

0.20mm).

The valve stem is clipped in the guide

pipe

Disassemble the valve, clean the

stem and guide pipe with diesel fuel.

3. Use remote jumper to test, if it works, the remote control unit fails and needs

replaced.

4. If remote jumper does not work, please turn electronic key to "ON" position,

use a multimeter (voltage tester) to measure the voltage on the solenoid, put

positive polarity to the conjunction of blue wire and solenoid and negative

polarity to engine case, you should read 12V in your meter. If the reading is

ZERO, the solenoid control board fails and needs replaced.

If there is 12VDC power to solenoid, please troubleshoot as follows:

1. Take off solenoid from fuel pump using two wrenches. You should use one

wrench to hold the solenoid firmly and turn counterclockwise to take it off fuel

pump, at the same time, you must use the other wrench to hold metal pipe of

fuel pump for avoiding its rotating. Take out a spring and a plunger in the

solenoid, replace the solenoid (means bypassing solenoid) to fuel pump, crank

the engine and see whether you can start or not; if works, solenoid is burned

and needs replaced.

2. If you cannot solve starting problem by bypassing solenoid, fuel pump or fuel

injector may have failed.

How to test fuel pump or fuel injector?

a. Loosen the end of high pressure metal fuel pipe to fuel pump, crank engine

and see whether you can see diesel popped out of fuel pump, if you can see

diesel out of pump, the pump is fine. Otherwise, fuel pump needs replaced.

Loading...

Loading...