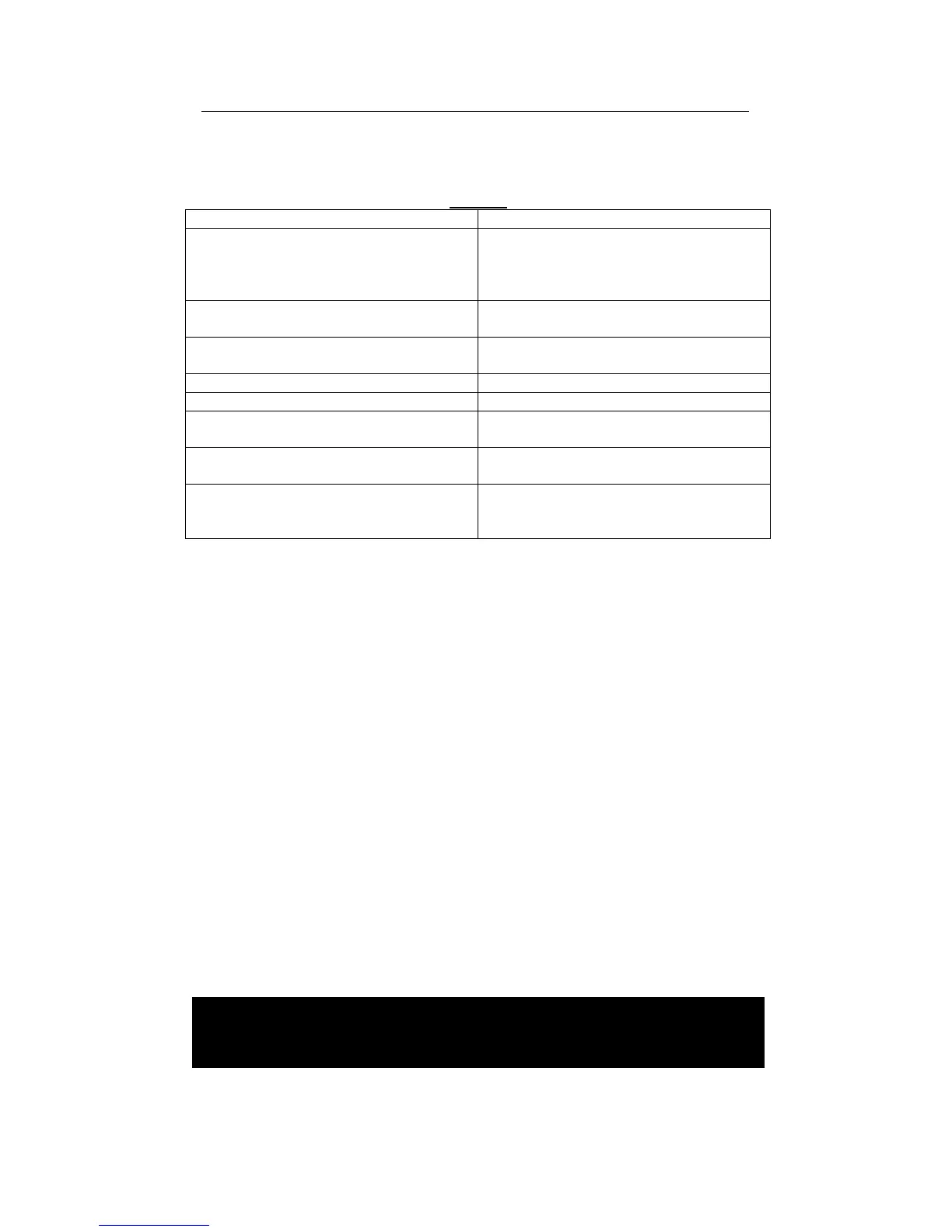

TROUBLESHOOTING

4-2.2 Causes and Troubleshooting for Deficient Power of

Diesel Engine

Table 6

Malfunction of fuel system

Parts obstruction in fuel filter and fuel

pipe

Inadequate fuel supplying

Check the fuel switch, they should be

opened fully.

Check the fuel filter and fuel pipe.

Bad pressing of fuel pump

Check or change the damaged parts of

the fuel pump.

Malfunction of the fuel nozzle

Incorrect injection pressure

Adjust the injection pressure.

Carbon deposit in the nozzle hole

Loose fit between needle and needle

body

Obstruction in air filter

Remove, clean or change the filter

core.

Not fast enough of engine speed

Check the speed of the engine with the

tachometer and then readjust the speed

limit bolts.

4-2.2.1 Instructions for speed adjustment

There are three bolts used in the speed limit system: left (C), middle bottom and

right (A) screws. Screws A & C are used for tightening metal plate B, A is also

used for fine adjustment of speed and middle bottom screw for setting

maximum fuel throttle. Please note that there is an oval-shaped hole in the

metal plate B with A through.

Screw A is used for fine adjusting RPM (Frequency < 5 Hz), moving B up

decreases RPM while moving B down increases RPM.

There are two rows of three small holes right behind the metal plate B and four

large holes in location E. If the adjusted frequency > 10 Hz, the thick spring D is

used for coarse tuning. Try to hook two ends of D in one of six small and four large

holes E respectively for obtaining desired frequency, e.g., if we need change

60Hz to 50Hz, this method will be involved. Given position of hooked small hole,

the obtained frequency decreases in the order from left to right holes of E;

given position of hooked large hole, the obtained frequency decreases in

the order from left to right small hole in the same row and upper to lower

small holes. Frequency adjustment shall be conducted with a frequency

meter.

Bolt F is preset for maximum power output position by manufacturer, it NEVER

touches fuel lever unless the maximum power output is reached. So, NEVER

adjust the position of threaded bolt.

CAUTION: If your generator runs unstable, e.g., runs at upper or lower, speed

and you excludes fuel system problem, you must try hooking the two ends of

coarse spring D in different small and large holes to find gut flexibly balanced

position.

Loading...

Loading...