Page

2

are provided to establish the continuous current rating of

each circuit breaker.

The Digitrip RMS 310 Trip Unit is completely self

-

con

-

tained and when the circuit breaker is closed, requires no

external power to operate its protection systems. It

operates from current signal levels and control power

derived through current sensors integrally mounted in the

trip unit.

Digitrip

RMS

31

0

Trip Units are suitable for

50/60

Hz

AC

applications only. For DC applications, a thermal

-

magnetic

trip unit should be used.

The Digitrip RMS 310 Trip Unit is available in 4 different

types, (see Table 1

-

1). Each trip unit contains a fixed long

delay time function (adjusted by changing the rating plug),

and may be equipped with a maximum of two phase and

two ground (time

-

current) adjustments to meet specific

application requirements. The types of adjustments

available for each model include the following:

Adjustment

1)

Short Delay Pick

-

up

2) Short Delay

Pick-up/Short Delay Time

3)

Short Delay Pick-up/Ground Fault

Pick-up/Ground Fault Time

4)

Short Delay Pick-up/Short Delay Time

Ground Fault

Pick-up/Ground

Fault Time

Tm

LESxxxLS,-LSE,-LSP

or MESxxxLS

or MESxxxLSl

LESxxxLSG,

or MESxxxLSG

LESxxxLS

I

G

or

MESxxxLSlG

LESXXXLS

I,

-

LS

I

E,

-

LS

I

P

2.0 UL LISTED DEVICES

The Digitrip

RMS

310 Trip Unit is listed in accordance with

Underwriters Laboratories, Inc. Standard

UL489, under

File E7819 and satisfies the applicable requirements of

the International Electrotechnical Commission (IEC)

recommendations for molded case circuit breakers.

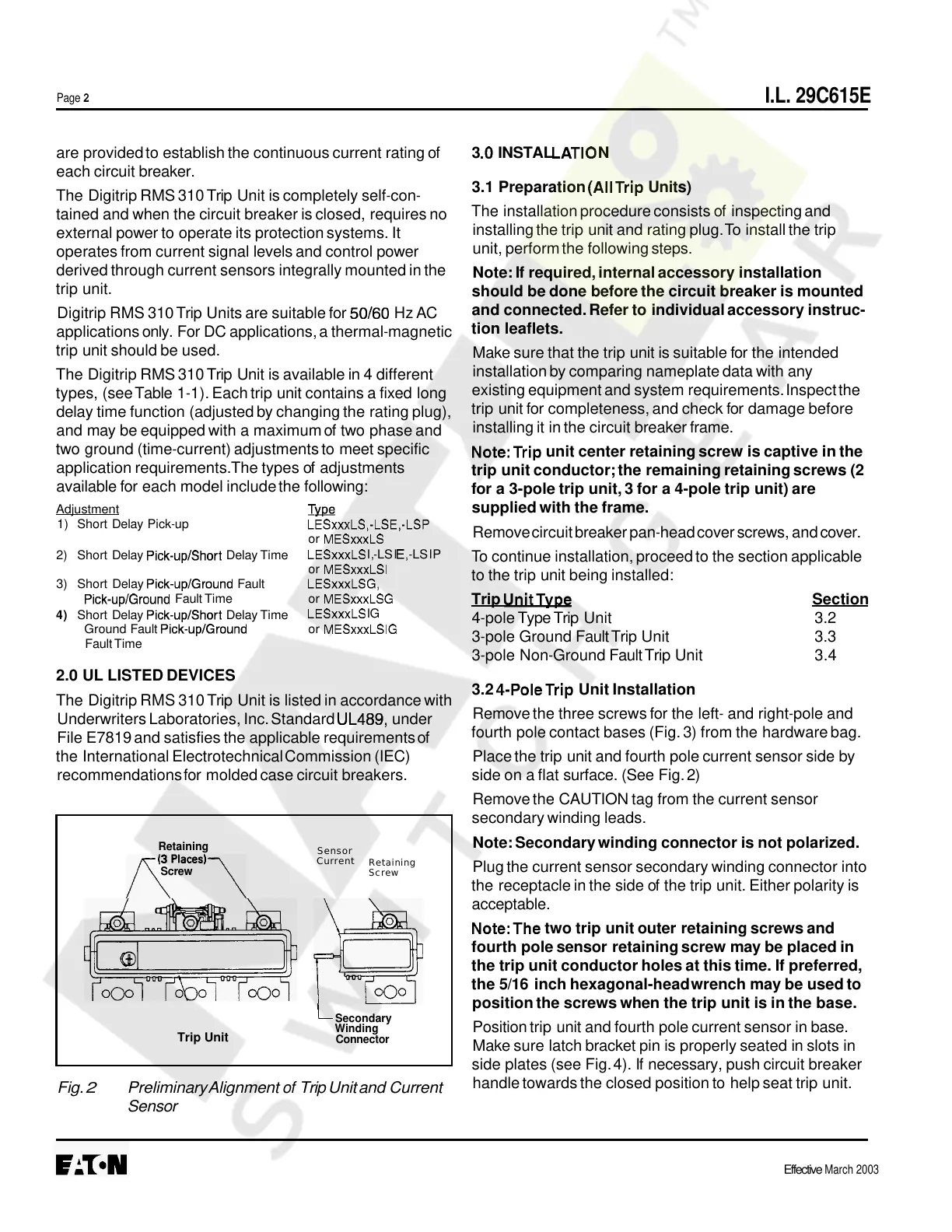

KPlaces)\

Screw

L

Secondary

Winding

Connector

Fig.

2

Preliminary Alignment

of

Trip Unit and Current

Sensor

3

.O

INSTAL LATlO N

3.1 Preparation

(AllTrip Units)

The installation procedure consists of inspecting and

installing the trip unit and rating plug. To install the trip

unit, perform the following steps.

Note: If required, internal accessory installation

should be done before the circuit breaker is mounted

and connected. Refer to individual accessory instruc

-

tion leaflets.

Make sure that the trip unit is suitable for the intended

installation by comparing nameplate data with any

existing equipment and system requirements. Inspect the

trip unit for completeness, and check for damage before

installing it in the circuit breaker frame.

Note:Trip unit center retaining screw is captive in the

trip unit conductor; the remaining retaining screws (2

for a 3

-

pole trip unit, 3 for a 4

-

pole trip unit) are

supplied with the frame.

Remove circuit breaker pan

-

head cover screws, and cover.

To continue installation, proceed to the section applicable

to the trip unit being installed:

Trip

UnitTvpe Section

4

-

pole Type Trip Unit 3.2

3.3

3.4

3

-

pole Ground Fault Trip Unit

3

-

pole Non

-

Ground Fault Trip Unit

3.2

4-PoleTrip Unit Installation

Remove the three screws for the left

-

and right

-

pole and

fourth pole contact bases (Fig. 3) from the hardware bag.

Place the trip unit and fourth pole current sensor side by

side on a flat surface. (See Fig. 2)

Remove the CAUTION tag from the current sensor

secondary winding leads.

Note: Secondary winding connector is not polarized.

Plug the current sensor secondary winding connector into

the receptacle in the side of the trip unit. Either polarity is

acceptable.

Note:The two trip unit outer retaining screws and

fourth pole sensor retaining screw may be placed in

the trip unit conductor holes at this time. If preferred,

the 5/16 inch hexagonal

-

head wrench may be used to

position the screws when the trip unit is in the base.

Position trip unit and fourth pole current sensor in base.

Make sure latch bracket pin is properly seated in slots in

side plates (see Fig. 4). If necessary, push circuit breaker

handle towards the closed position to help seat trip unit.

Effective

March 2003

I.L. 29C615E

Trip Unit

Current

Retaining

Sensor

Retaining

Screw

Courtesy of NationalSwitchgear.com

Loading...

Loading...