2

Instructional Leaet IL03902001E

Effective February 2011

S811 quick installation guide

EATON CORPORATION www.eaton.com

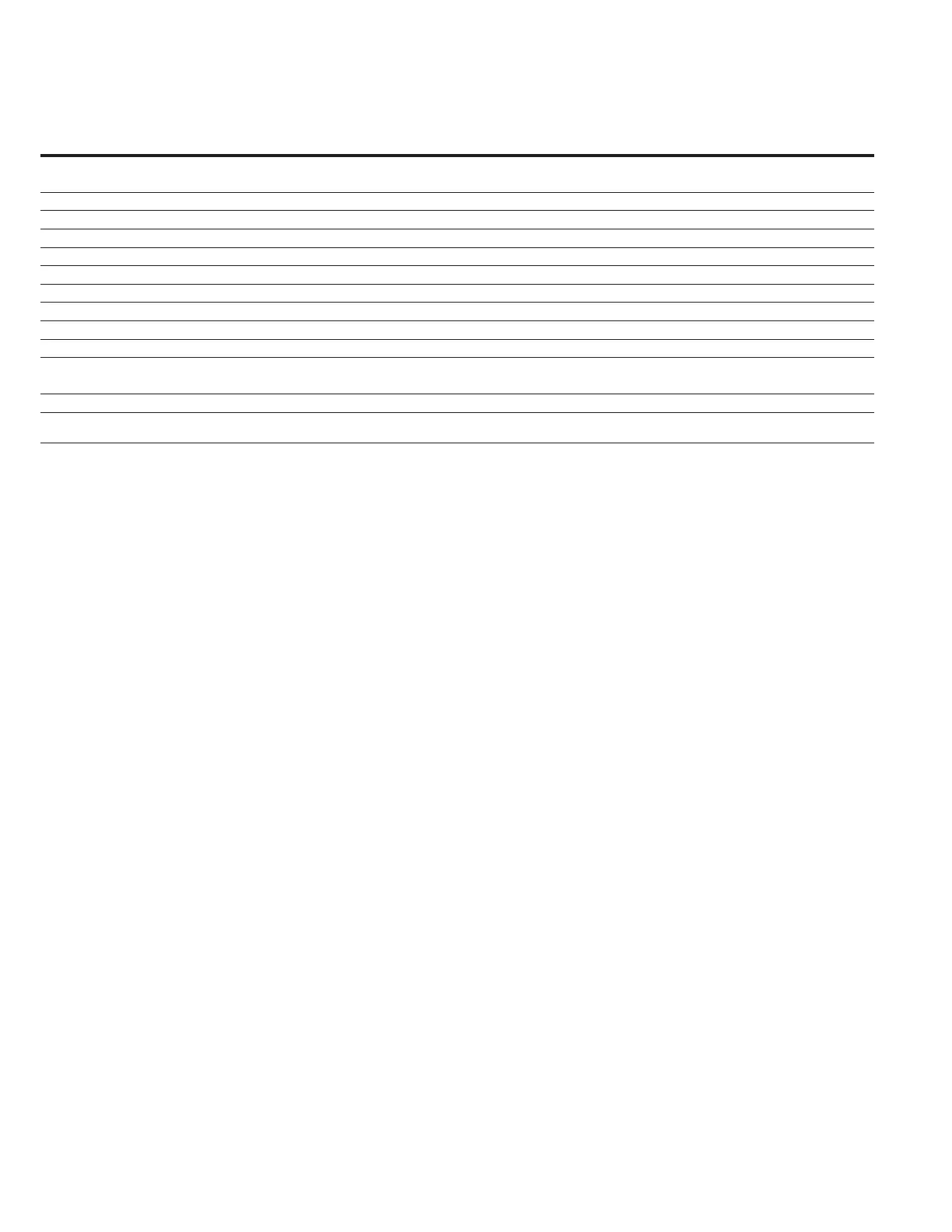

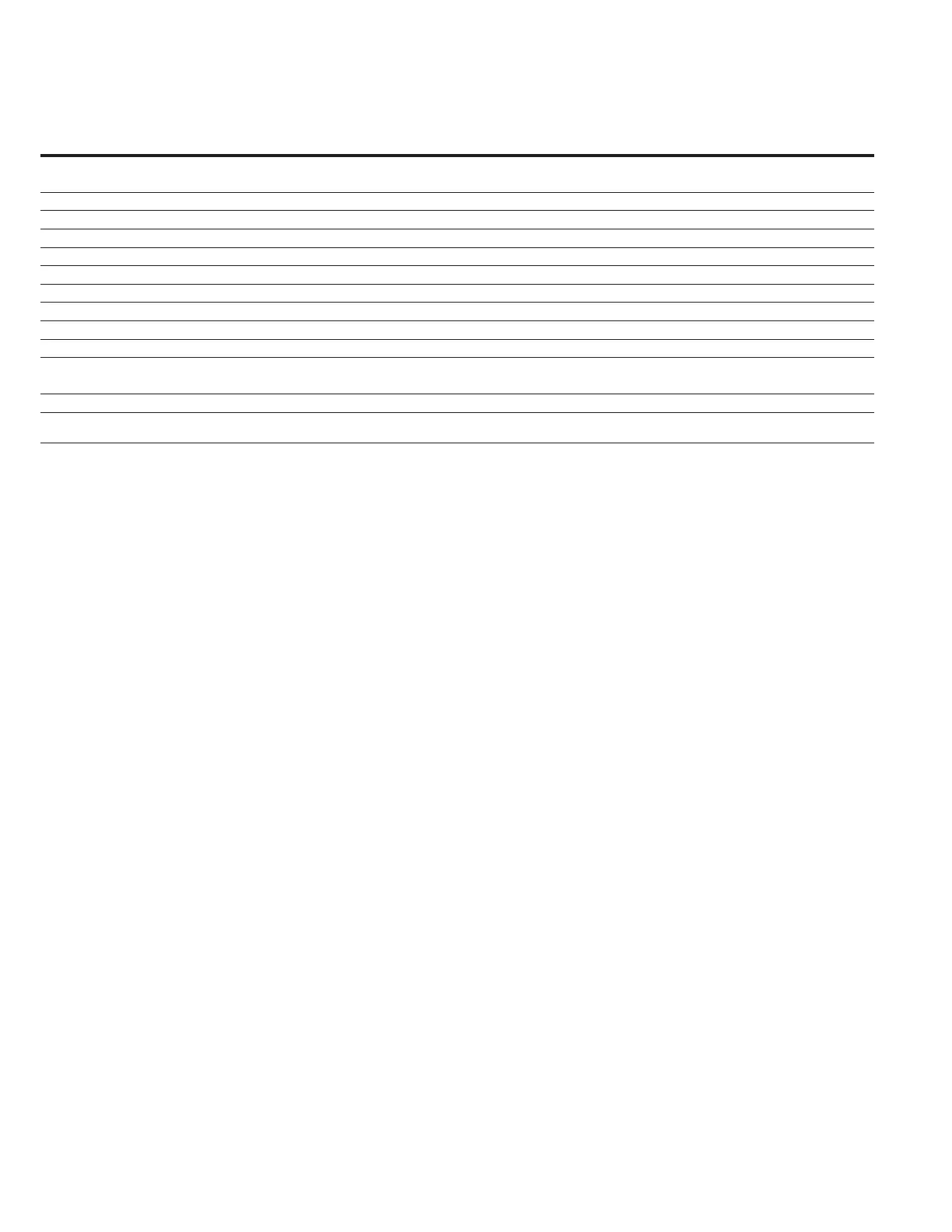

Table 1. Settings for Typical Applications

Parameter

Factory

Setting Pump

a

Fan

Unloaded

Conveyor

Rock

Crusher Saw Compressor

Configuration Menu

Overload trip FLA 21 Motor FLA Motor FLA Motor FLA Motor FLA Motor FLA Motor FLA

Overload trip class 5 20 20, 30 20 30 30 20

Start method 0 (voltage ramp) 3 (pump control) 0 (voltage ramp) 0 (voltage ramp)

b

0 (voltage ramp)

b

0 (voltage ramp)

b

0 (voltage ramp)

b

Soft start time 20 20 40 20 30 30–50 10

Initial torque 25 55 65 50 70 65 45

Kick start time 0 0 0 0 85 0 0

Kick start torque 0 0 0 0 2 0 0

Soft stop time 0 N/A 0 Load dependent 0 0 2

Pump stop time 120 30 0 0 0 0 0, 2

c

Start control Level Level Level Edge Edge Edge Level

Protections Menu

Phase imbalance fault Enabled Enabled

d

Enabled

d

Enabled

d

Enabled

d

Enabled

d

Enabled

d

Phase sequence ABC ABC ABC ABC ABC ABC ABC

Motor rated voltage 480 Rated system

voltage

Rated system

voltage

Rated system

voltage

Rated system

voltage

Rated system

voltage

Rated system

voltage

a

Starter must be ordered with pumping software installed.

b

A value of one (current limit start) may be selected for this application, but longer starting times and constant loads should be observed when starting.

c

Two second stop time must be set if this is an ammonia compressor application.

d

Customers operating equipment on either ungrounded systems or high resistance grounded systems may need to adjust the severity and/or duration of imbalance protection.

These power systems periodically experience phase angle shifts that can be picked up as a false imbalance trip.

Loading...

Loading...