27

FUEL SYSTEM

CS-370ES

CS-420ES

4-7 Adjusting carburetor

4-7-1 General adjusting rules

A. Before starting the unit for adjustment, check the following items.

1. The correct spark plug must be clean and properly gapped.

2. The air filter element must be clean and properly installed.

3. The muffler exhaust port must be clear of carbon.

4. The fuel lines, tank vent and fuel filter are in good condition and clear of debris.

5. The fuel is fresh ( > 89 octane : RON

) and properly mixed at 50 : 1 with “ISO L-EGD” or “JASO-FC/FD”

2-stroke oil.

6. The recommended bar and chain must be installed, and properly tensioned.

NOTE : In order to achieve proper carburetor adjustment, 35 or 38 cm bar and chain should be installed on

the unit. Otherwise serious engine damage will occur due to overspeeding.

B. Start and run engine for two minutes alternating rpm between WOT and idle every 5 seconds. Turn L

and H mixture needles full anticlockwise. Adjust idle speed screw to 2,650 +/- 250 rpm. If engine does not

run correctly after this adjustment, proceed to the next step 4-7-2.

IMPORTANT : After adjusting carburetor according to the steps 4-7-2 and 4-7-3, the limiter cap(s)

must be installed on L and H mixture needle(s) to comply with Emission Directive.

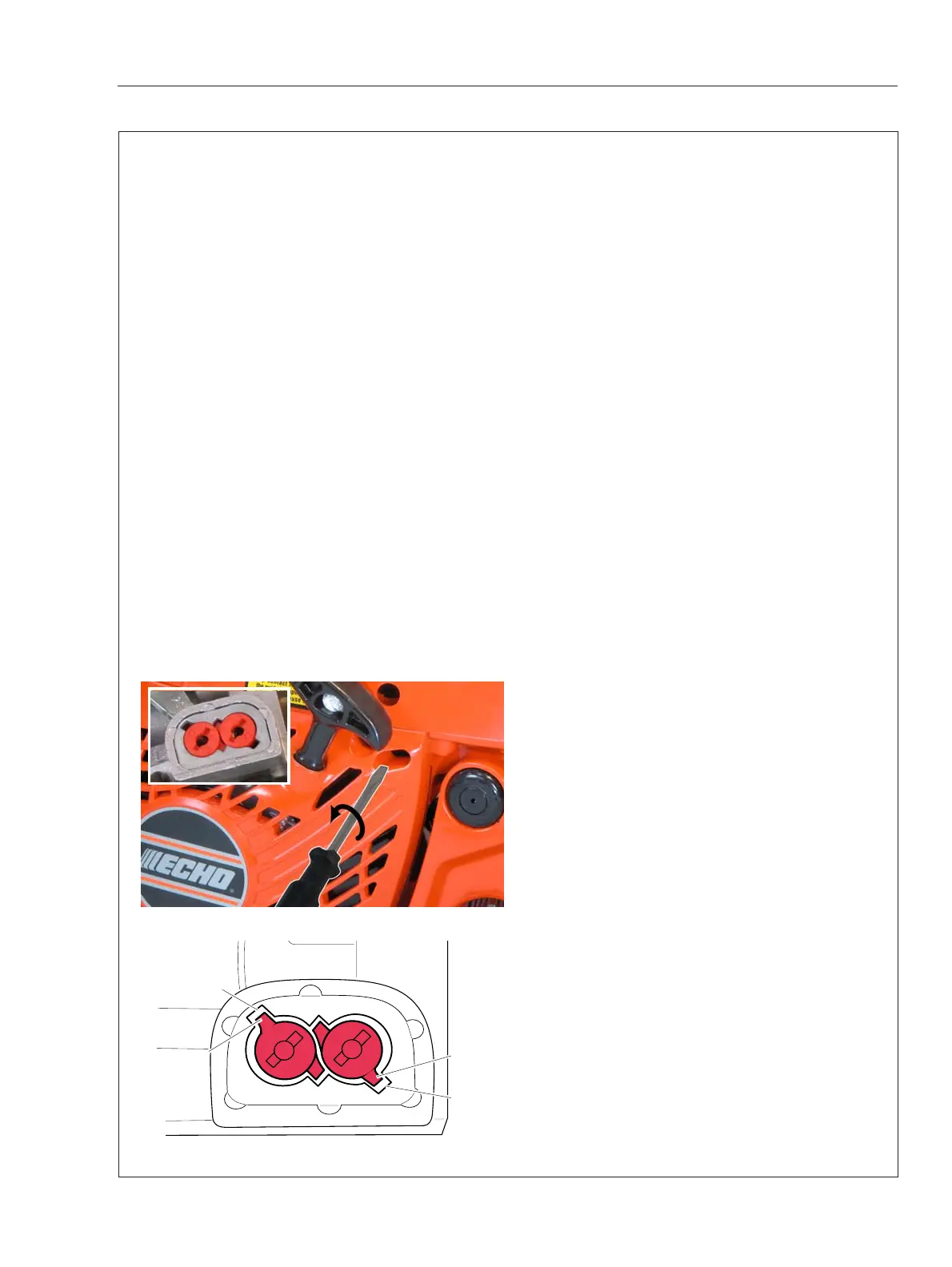

4-7-2 Presetting idle adjust screw, L mixture needle and H mixture needle

Tools Required: Small screwdriver with 2.5 mm

blade, P/N 897801-33330 electronic tachometer,

P/N 91019 limiter cap removal tool.

Parts Required : (2) P/N P003-000010 limiter caps.

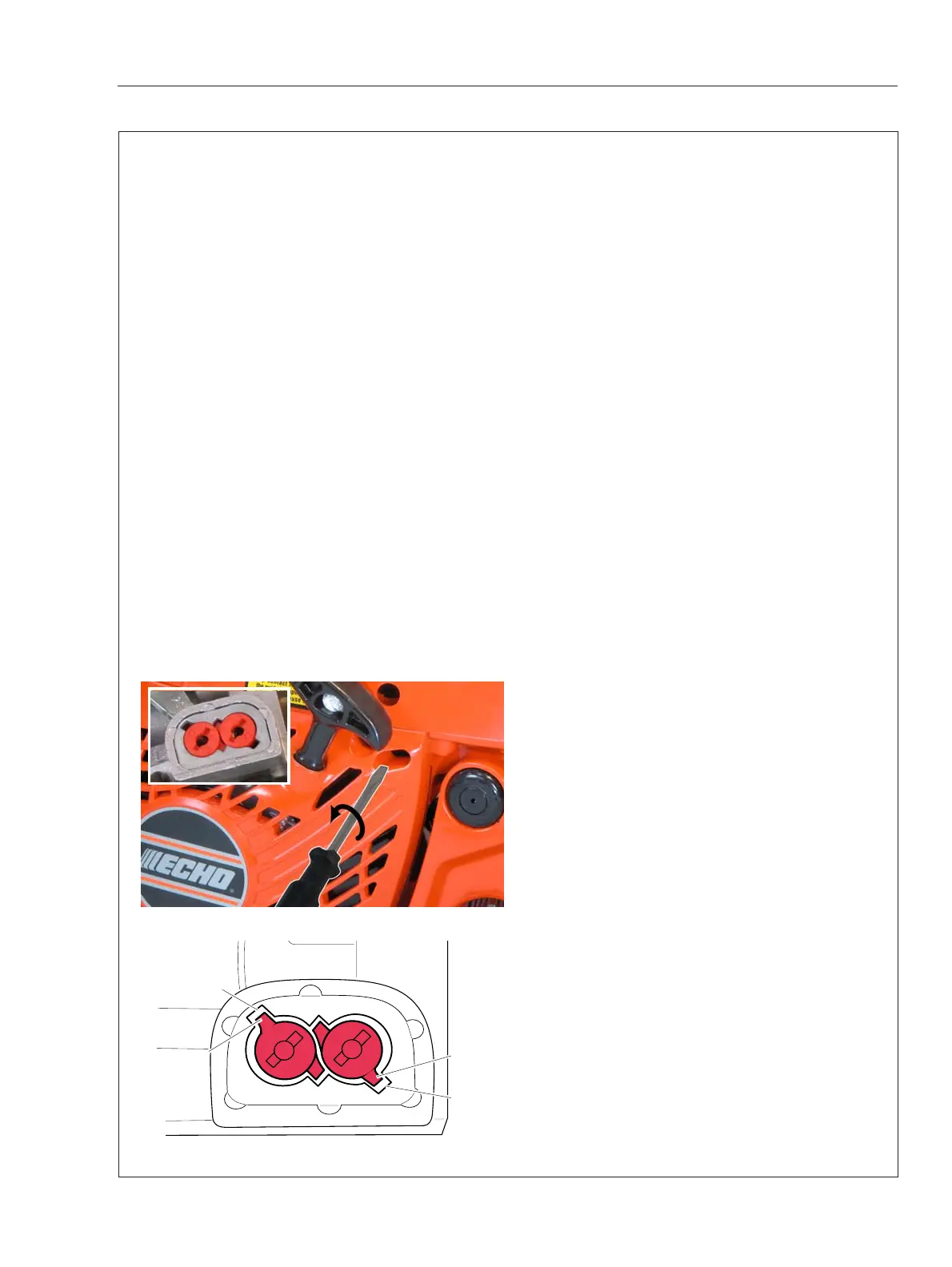

1. Turn the L and H mixture needles anticlockwise

to rich side stop to align limiter cap tab (A) with

locating slot (B), using 2.5 mm blade screwdriver.

NOTE: If cap tabs (A) misalign with locating slots

(B), there is possibility of stripping the threads made

by the removal tool when removing the limiter caps.

B

A

A

B

Loading...

Loading...