SERVICE INFORMATION

GT-220ES

SRM-220ES

4

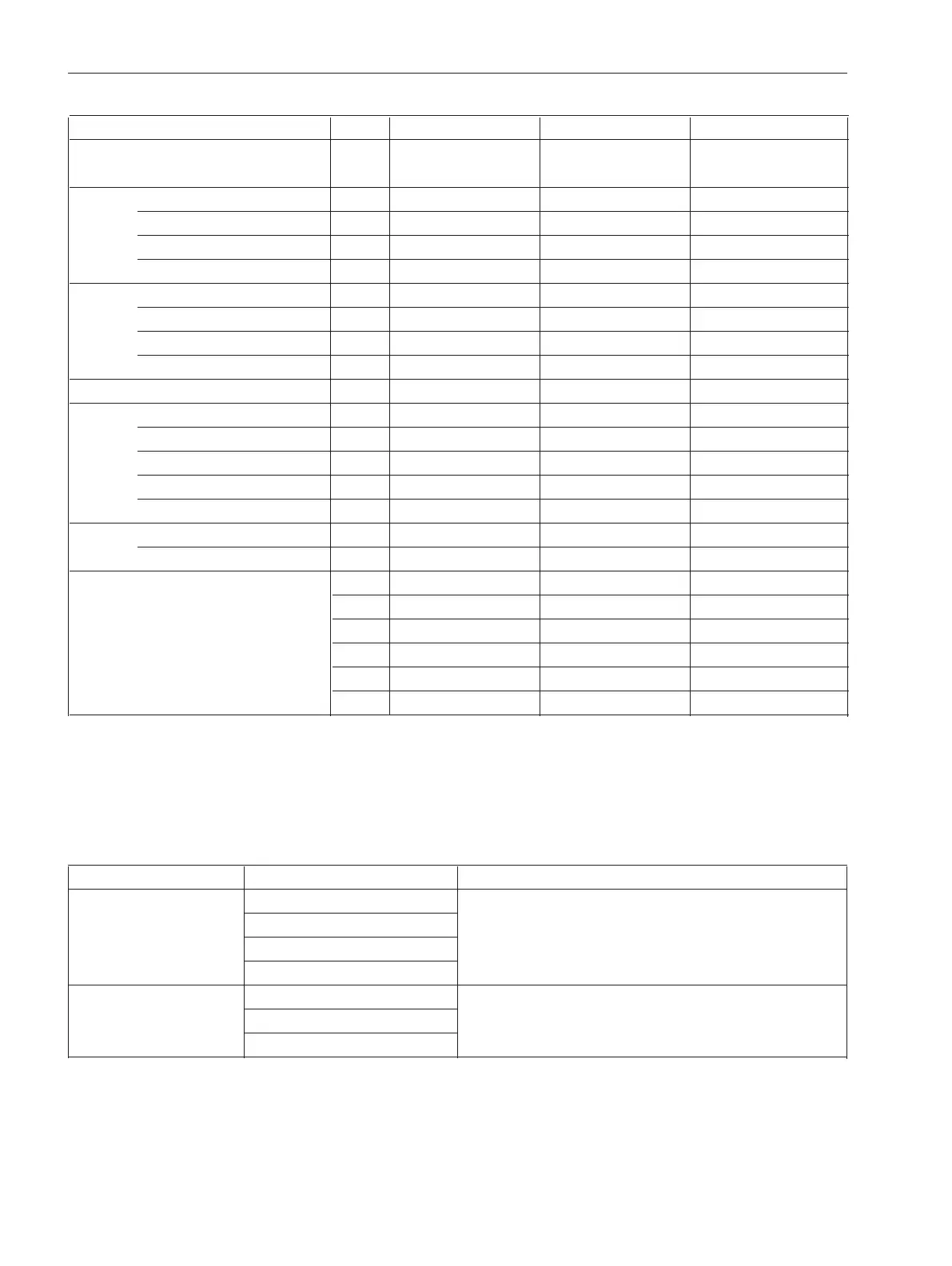

1-3 Torque limits

Descriptions Size

kgf•cm

N•m

in•lbf

Starter Starter case

M 4 14 - 28 1.4 - 2.8 12 - 24

system

Ignition Ignition coil M 4 30 - 50 3 - 5 26 - 45

system

Fan cover M 4** 14 - 28 1.4 - 2.8 12 - 24

Spark plug M 14 150 - 170 15 - 17 130 - 150

Ground lead terminal M 4** 20 - 40 2 - 4 18 - 35

Fuel Intake insulator M 5** 25 - 40 2.5 - 4 22 - 35

system

Carburettor M 5 30 - 40 3 - 4 26 - 35

Throttle cable nut M 6 25 - 35 2.5 - 3.5 22 - 30

Fuel tank M 5** 30 - 45 3.0 - 4.5 26 - 40

Clutch Clutch hub M 8 120 - 160 12 - 16 100 - 140

Engine Crankcase M 5

†

70 - 100 7 - 10 60 - 90

Cylinder M 5

†

70 - 100 7 - 10 60 - 90

Cylinder cover M 4 14 - 28 1.4 - 2.8 12 - 24

Muffl er M 5 60 - 100 6 - 10 52 - 85

Top guard M 5* 15 - 25 1.5 - 2.5 13 - 22

Others Trigger holder assembly M 5 35 - 55 3.3 - 5.5 30 - 48

Trigger holder assembly band

M 5 20 - 40 2 - 4 18 - 35

Regular bolt, nut and screw M 3 6 - 10 0.6 - 1 5 - 9

M 4 15 - 25 1.5 - 2.5 13 - 22

M 5 25 - 45 2.5 - 4.5 22 - 40

M 6 45 - 75 4.5 - 7.5 40 - 65

M 8 110 - 150 11 - 15 95 - 130

M 10 210 - 300 21 - 30 180 - 260

*Tapping screw ** Apply thread locking sealant. (See below)

†

The torque differences among bolts should not exceed 20 kgf•cm (2N•m, 17in•lbf) on one cylinder or

crankcase.

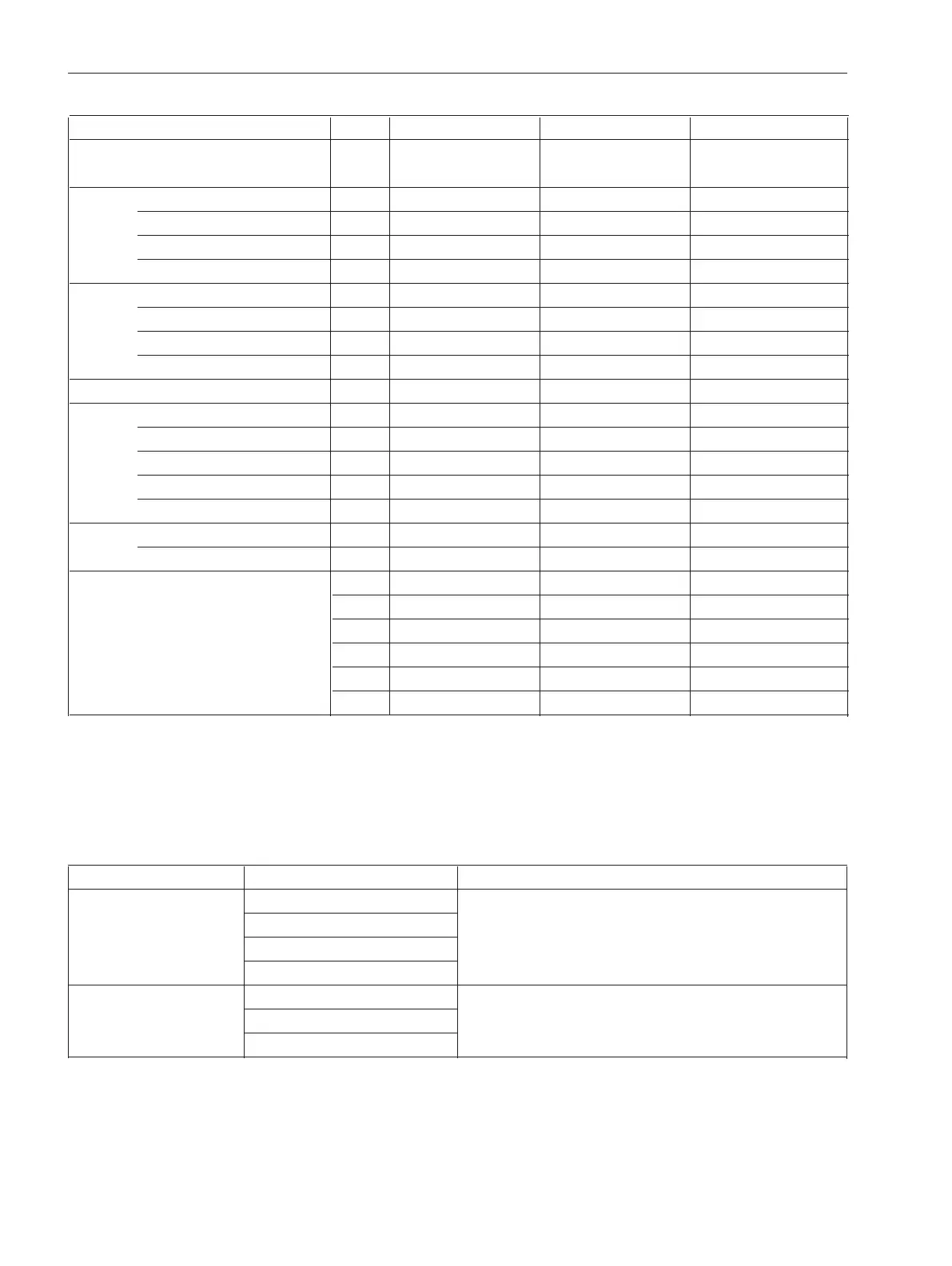

1-4 Special repairing materials

Material

Location

Remarks

Thread locking sealant Fan cover

Intake insulator

Ground lead terminal

ThreeBond 1342 or equivalent

Fuel tank

Grease Gear case

Rewind spring Lithium based grease

Starter center post

Loading...

Loading...