9

www.ecoflam-burners.com

EN

420010370401

The E-BCU OIL fuel oil control and safety unit controls and monitors the forced draught burner. The microprocessor- controlled

program sequence ensures maximum stability of time periods, regardless of fluctuations in the power supply or ambient temperature.

The design of the automatic combustion control unit protects it from the effects of brownouts. Whenever the supply voltage drops

below its rated minimum level (170 V), the control unit shuts down - even in the absence of a malfunction signal. The control unit

switches itself back on again once the voltage has exceeded the 178 V.

Locking and unlocking the system

The control unit can be locked (switched to malfunction) and unlocked (malfunction cleared) by pressing the R reset button, provided

the system is connected to the mains power supply.

R

RJ45

R- Reset button + lock-out led.

RJ45 - Connector for PC interface (diagnostic, separate item).

LINE Electrical supply

BV... Fuel valve

FS Flame signal

M Burner motor

OW Release contact of oil preheater

W Control thermostat or pressurestat

Z Ignition transformer

1 No voltage

2 Power supply on, no heat request

3 Heat request: pre-heater ON

4 Preventilation: motor ON, ignition ON

4’ Parasitic flame monitoring

5 Burner start: solenoid valve OFF, flame

production, safety time

6 Flame present, post-ignition period

7 Burner operation

8 End of heat request, solenoid valve

closes, burner stop

9 Standby

!

Always disconnect the power supply before installing or removing the control unit. Do not attempt to open or carry out repairs

on the control unit.

Function - E-BCU OIL control and safety unit

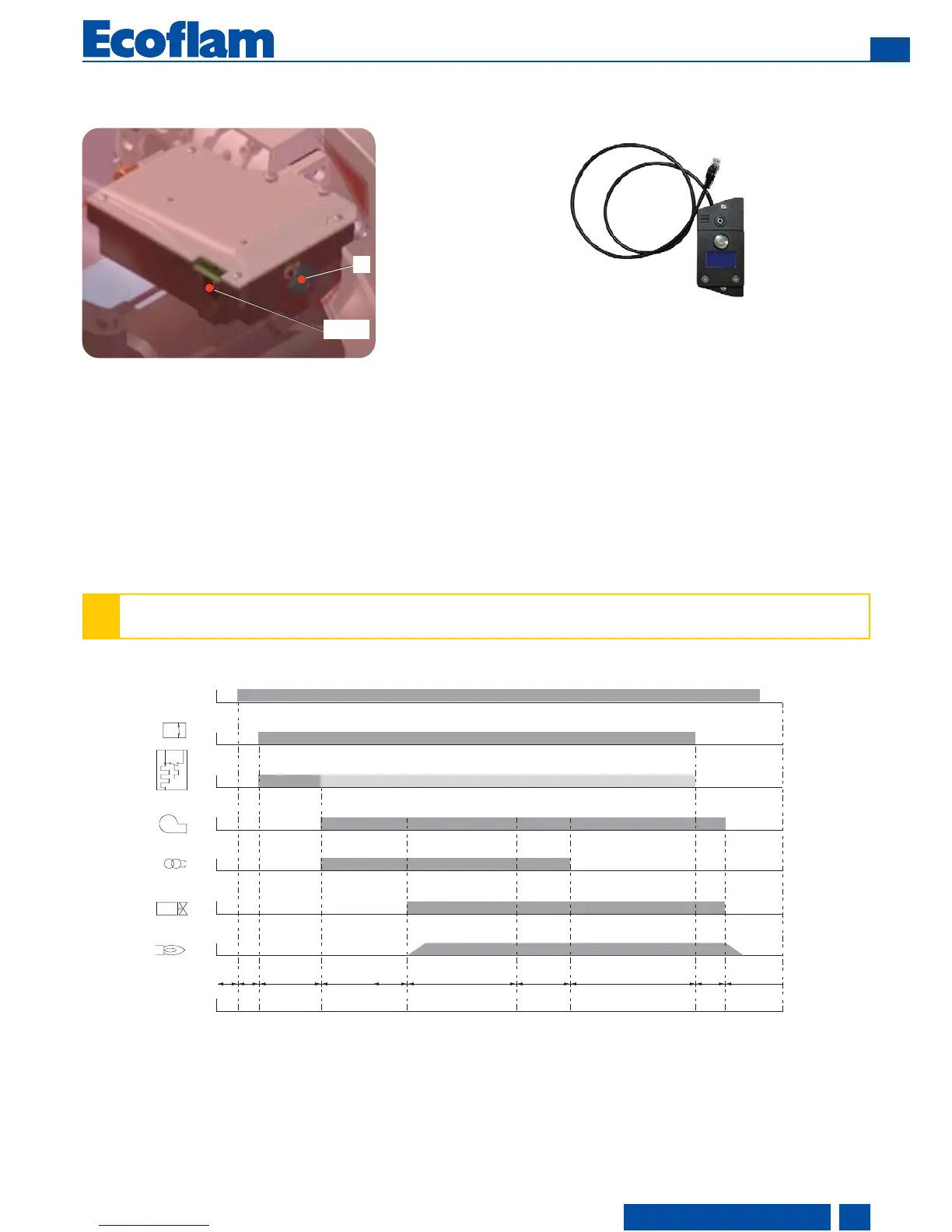

KIT E-BCU

DIAGNOSTIC TOOL

(not supplied)

Loading...

Loading...