Figure 4

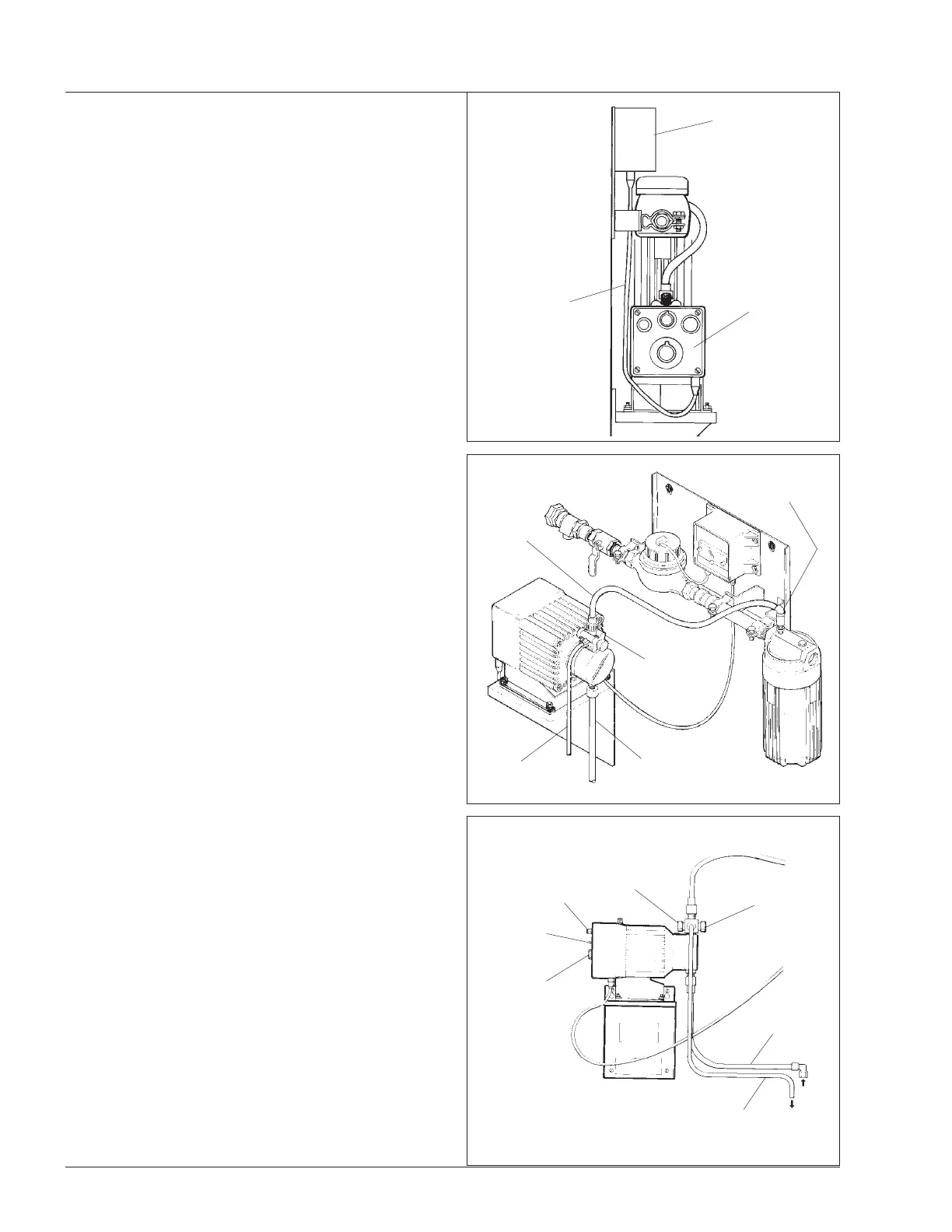

Figure 5

Figure 6

NOTE - insure pump is mounted close enough to flow

meter manifold assembly for the length of cable con-

nector wire available from the programmable divider.

5. Using the drum probe, 1/2" (12.7mm) tubing and fittings

provided, plumb the drum probe to the bottom connector

on the pump head,

refer to Figure 5.

NOTE - For products that gas off, do not use the drum

probe. The tubing should be flexible and as short as

possible. The product drum must be placed directly

under the pump.

Using the 1/2" (12.7 mm) tube and hose clamp provided,

plumb the output port, which is the one on the top of the

anti-siphon valve on the pump, to the injection point on the

mixing chamber of the manifold assembly. Connect the

pump to 120VAC/60Hz electrical supply.

Connect 1/4" (6.4 mm) tubing, which is provided to the

tubing nut on the anti-siphon valve on the pump head, and

run it back to the drum or the drain. This is for pressure

relief during priming.

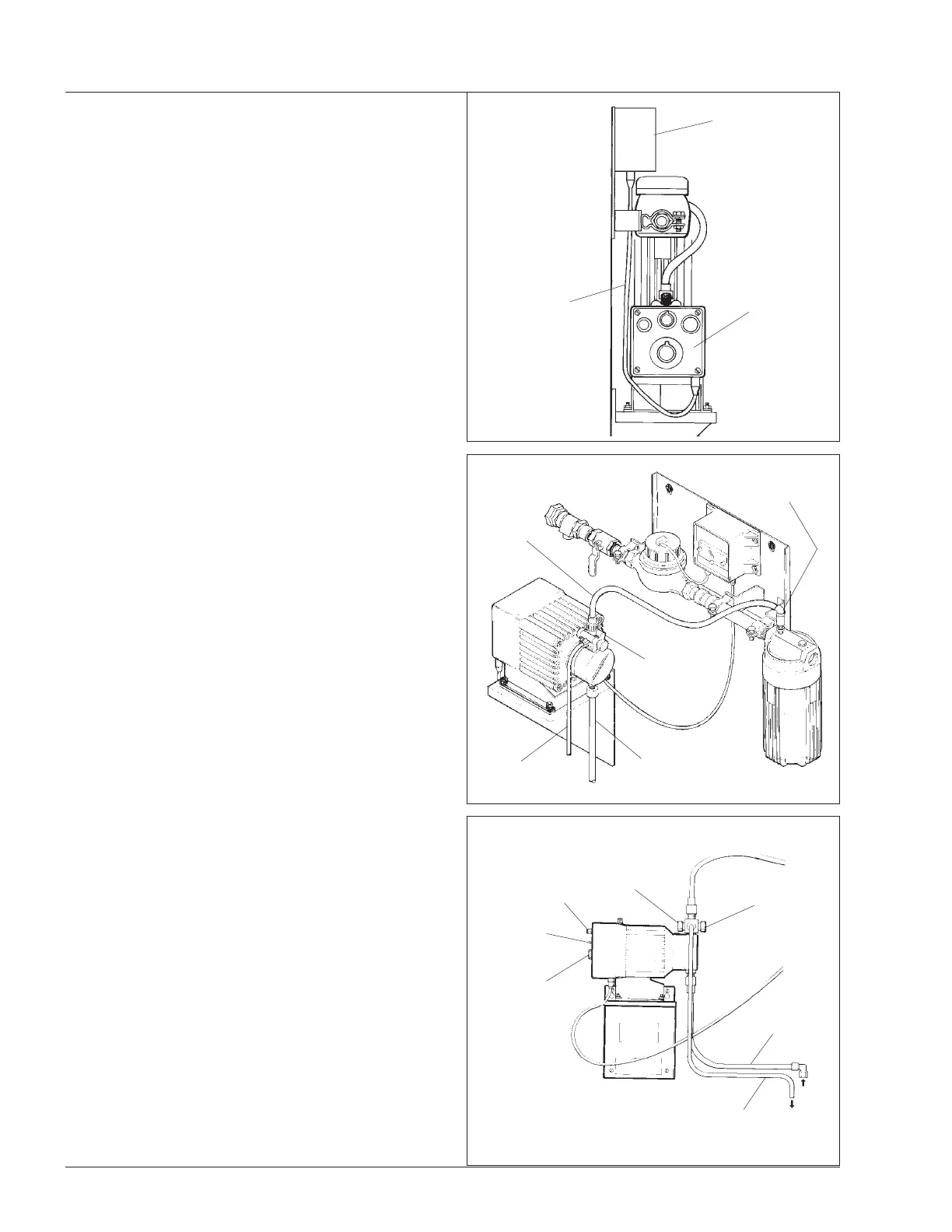

6. Place the pump switch in the INTERNAL position. As the

pump is running, set the stroke length knob at 60% (all

dosage ratio calculations are based on 60% stroke length),

refer to Figure 6.

Set the speed control switch on the pump at 100% and

with the pump switch in the internal position, grasp the

black and yellow knob on the pump anti-siphon valve and

pull outward on both until the product rises in the suction

tube and starts to come out the 1/4" (6.4 mm) bypass tube.

(Priming is best accomplished with the speed switch set

on 100%). The pump is now primed.

SET THE SELECTOR SWITCH ON THE PUMP TO THE

EXTERNAL POSITION.

4

PUMP CONTROL

PANEL

OUTPUT

TUBING

DRAIN

TUBING

DRUM PROBE

TUBING

ANTI-SIPHON

VALVE

INJECTION

POINT

YELLOW

KNOB

BLACK

KNOB

SPEED

CONTROL

PUMP

SWITCH

STROKE

LENGTH

FROM

PRODUCT

TO DRAIN

PROGRAMMABLE

DIVIDER

PUMP TO

PROGRAMMABLE

DIVIDER

CONNECTION

Loading...

Loading...