HD-KL18-0623

Page 12

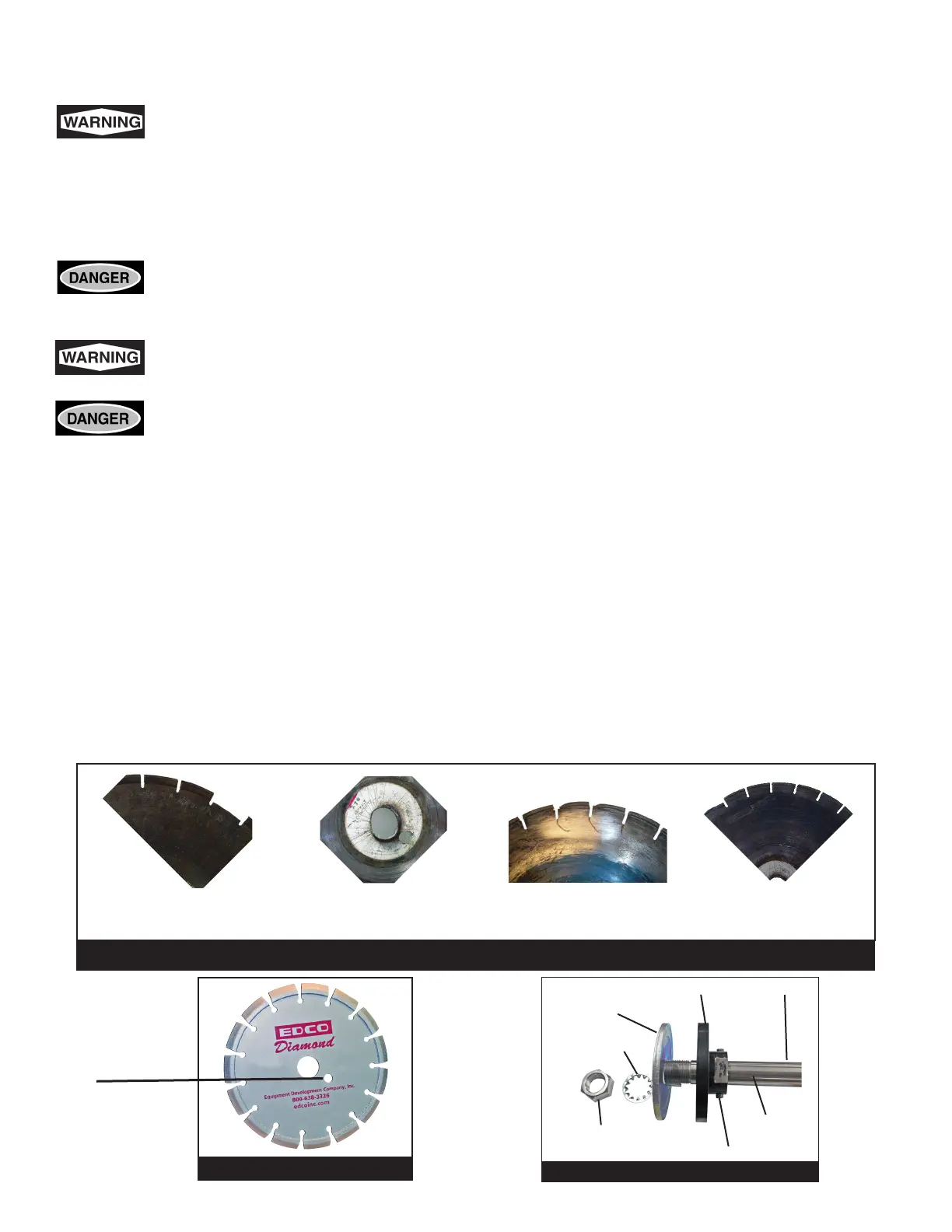

Arbor Shaft

Figure 5

Blade Cap

retaining Nut

Blade Retaining

Cap

Backing Plate

Drive Pin

Drive Pin Hole

Internal tooth

Lock Washer

Changing Blades

Disconnect the machine from the power source before performing any work on the equipment (i.e. changing the

blade). To disconnect the power source on gasoline engine models, remove the spark plug lead. On electric models,

unplug the electrical power cord at the machine.

• Make sure you have the proper blade for the job. Determine the hardness and composition of the slab. Give your dealer

complete information including whether re-bars are present, the desired depth of the cut, and length of the cut. If in doubt,

contact the blade manufacturer.

Inspect the blades before installing. Check diamond blades for cracks, loose segments and oversize, worn, or

out-of-round arbor holes (See below). Do not use any questionable blade since serious personal injury and/or

damage to property can result. Do not use warped, twisted, or out-of-balance blades. Unbalanced blades will

wear excessively, vibrate and damage both arbor shaft and bearings. Do not use blade without a drive pinhole

(Figure 4).

For safety reasons, EDCO does not recommend the use of any abrasive blades. Abrasive blades can break

and cause serious personal injury to operator and/or bystanders. If abrasive blades are used by choice, use

only reinforced abrasive blades. Inspect blades carefully.

Never exceed the maximum operating speed of the blade. Be sure to match the blade speed rating with the

arbor shaft speed on the machine. The KL-18 has an arbor shaft speed (unloaded) of 3000 RPM.

• Do not remove or lift the blade guard unless machine is stopped and all power is disconnected. Be sure to reinstall blade

guard before reconnecting the power source.

• Be sure the arbor shaft, backing plate, and blade cap are clean and in good condition. Make sure the threads are clean and

undamaged. If any damage is detected, consult your EDCO dealer (or the EDCO factory).

• The backing plate and blade cap (Figure 5) should be the same diameter, do not use if they are dierent diameters. For

abrasive blades and for all steel centered diamond blades, the backing plate and blade cap must be at least 1/4 the

diameter of the blade.

• The drive pin should be tight in the blade cap and long enough to t through blade and into hole in backing plate.

• Place the blade on the arbor shaft and turn until the drive pinhole lines up with the backing plate.

• Place the blade cap on the arbor shaft so the drive pin goes through the holes in the blade and backing plate.

• Put washer and arbor shaft nut and tighten arbor shaft nut.

• Secure the blade guard in the operating position before reconnecting the power supply or starting engine.

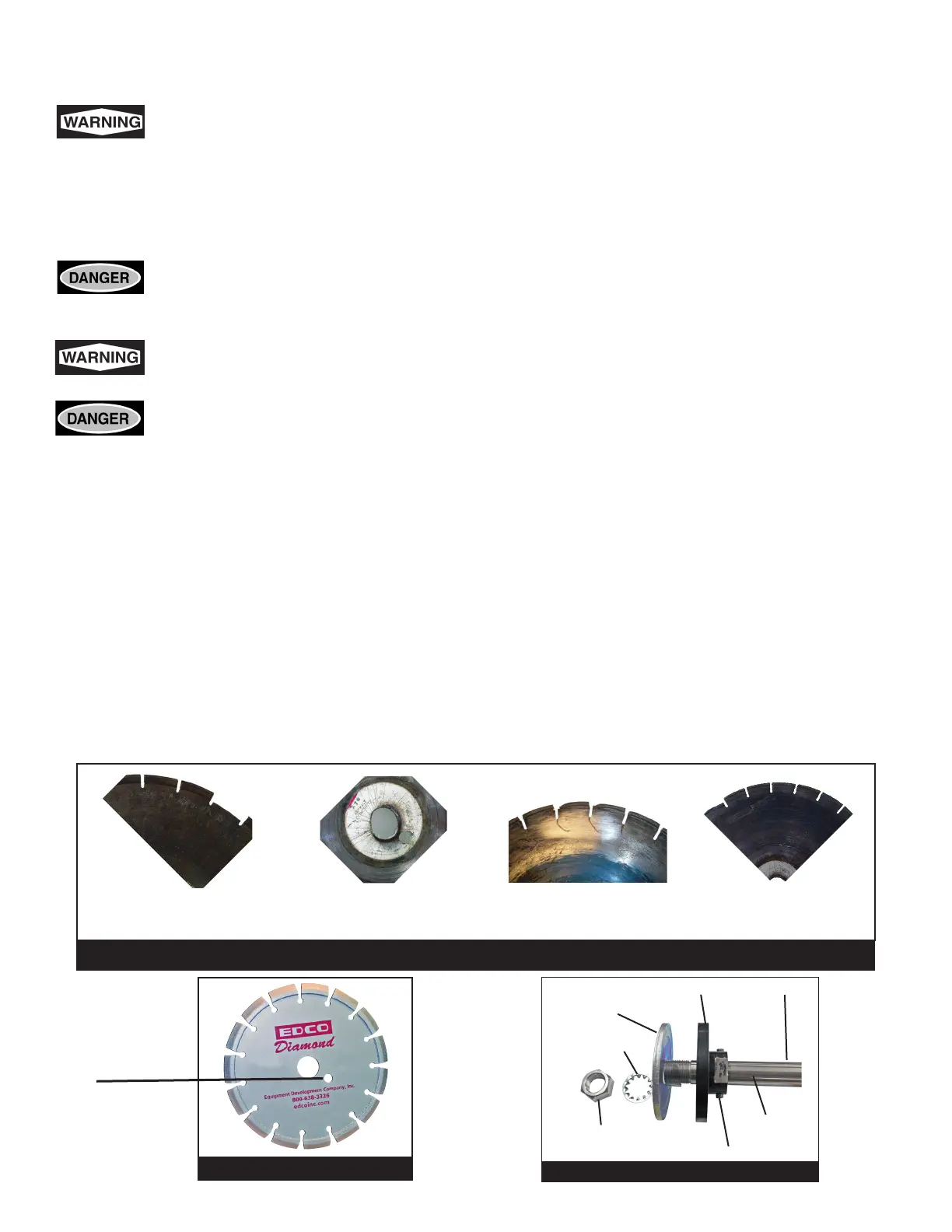

Possible Diamond Blade Problems

Segment Loss:

Usually insucient water

Arbor Hole Out-of-Round:

Blade not properly tightened or

seated on arbor

Cracked Segments

and/or Core:

Wrong blade for the job

Blade Will Not Cut:

Blade is glazed or to

hard for the job

Drive Pin Hole

Figure 4

Loading...

Loading...