A735-01-860 Issue A

Page 8 © Edwards Limited 2012. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Connection for serial control and monitoring

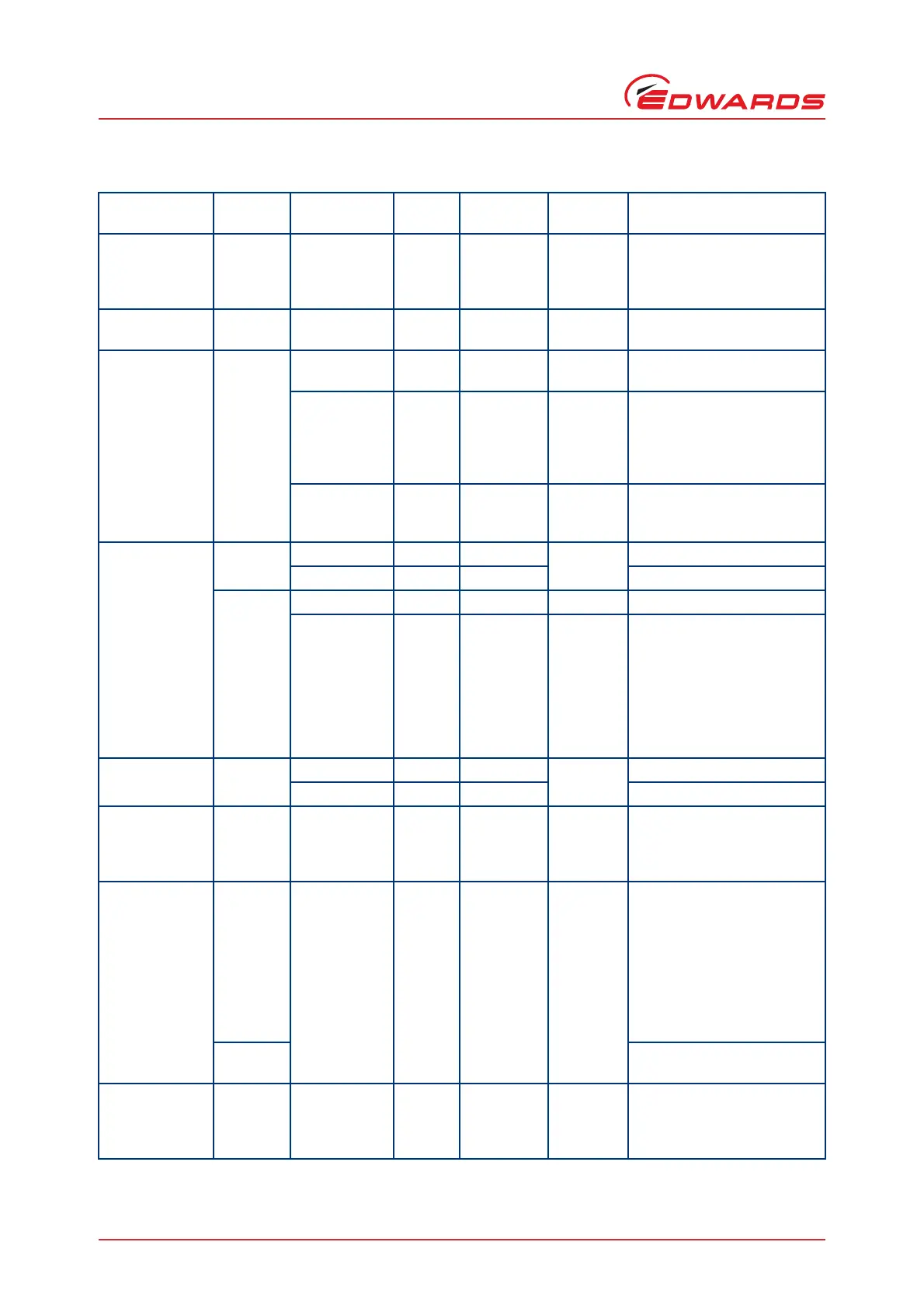

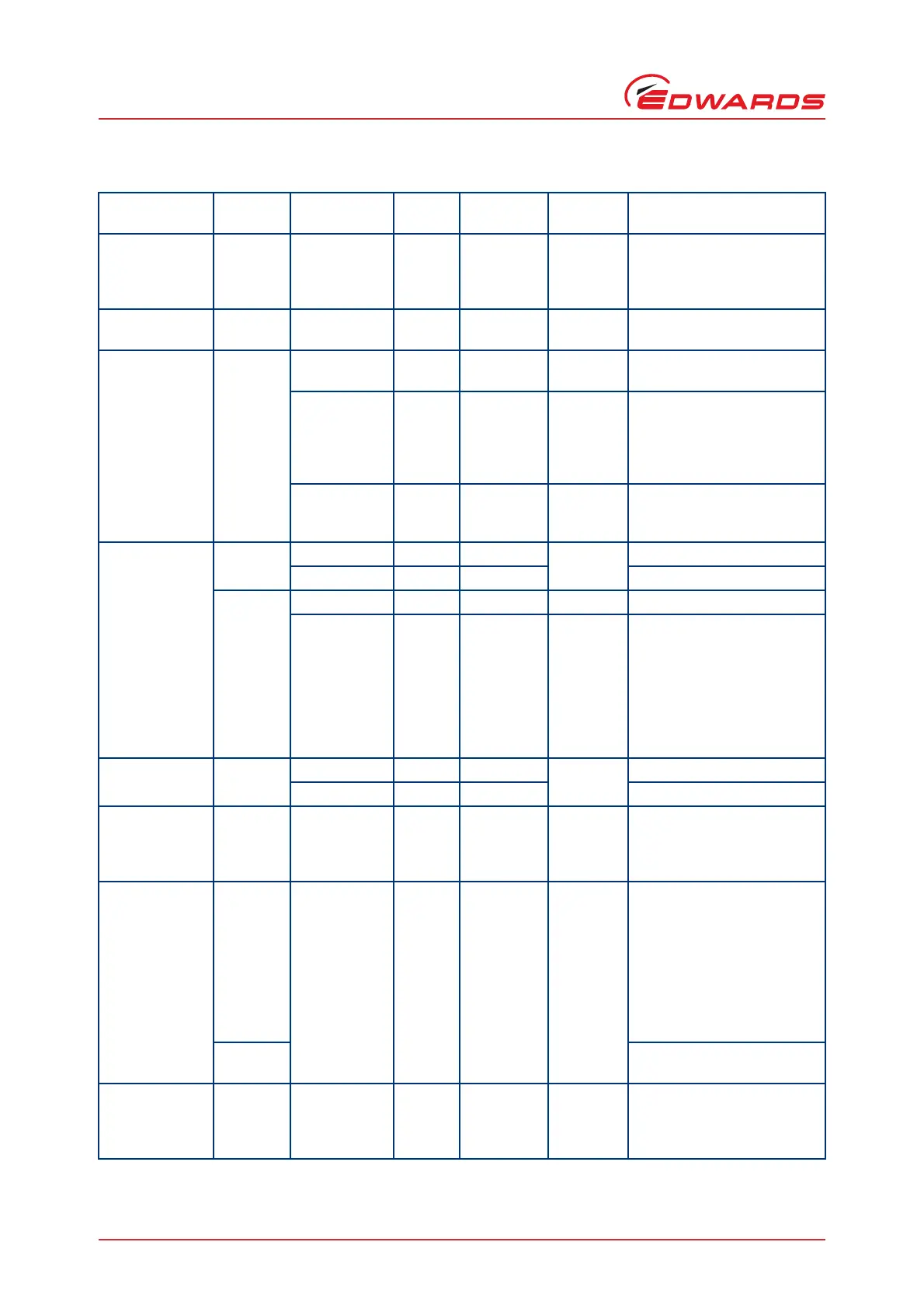

Table 3 - Summary of the commands that can be sent to the nXDS pump

Object name Command

Parameter

range

Factory

setting

Data type Units Comments

Identification ?S0 - - - -

Acts as wildcard object num-

ber to identify

instrument.

Reply identical to ?S801

Node

?S800

!S800

0..98 0 Decimal

Slave

Address

Multi-drop address (RS485)

0 = disable multi-drop mode;

Pump type ?S801

[1..8] - String

ASCII

Characters

Pump type (nXDS)

[1..11] - String

ASCII

Characters

Motor-Control Software

Version number (Dxxxxxxxx Y)

(where Dxxxxxxxx is the

drawing number and Y is the

revision)

1..255 - String Hz

Design frequency (= Nominal

mechanical frequency of the

pump)

Pump control

!C802

0-Decimal

-

Stop the pump

1 - Decimal Start the pump

?V802

0..255 - Decimal Hz Reported motor frequency

64-bits

encoded as

four

16-bit words:

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>;

<0000..FFFF>

-

Hexadeci-

mal

-

System status:

System status register 1;

System status register 2;

Warning register and Fault

register

*

Speed control !C803

0-Decimal

-

Use full speed

1 - Decimal Use standby speed

Normal speed

threshold

?S804

!S804

50..100 80 Decimal %

Normal speed status output

trigger level:

Percentage (%) of selected

speed

Standby speed

setting

?S805

!S805

66..100 70 Decimal %

Standby speed of pump:

Percentage (%) of full

mechanical speed (see 801)

!S stores standby speed to

non-volatile memory

(use !C805 for real-time

speed control, faster

execution and extended non-

volatile memory life)

!C805

!C retains value in volatile

memory only

Auto-run

?S806

!S806

0

1

0 Decimal -

Run the nXDS Pump-System

from power-on:

Enable = 1

Disable = 0

Loading...

Loading...