7

GB-016C_f.493

ALL WIRING MUST BE CARRIED OUT IN ACCORDANCE WITH

CURRENT IEE REGULATIONS. BS 7671

ALL ELECTRICAL CONNECTIONS MUST BE MADE BY A QUAL-

IFIED TRADESPERSON.

A load check should be carried out to ensure that there is a suf-

ficient current and voltage for the intended boiler installation.

Consideration should be taken into account with regard to the

remainder of the properties load requirements.

All boilers must be protected at the meter position with a double

pole fused switch with a minimum of 3mm contact separation. If

the boiler is not fitted local to the meter position then an isolation

switch must be fitted local to the boiler.

THIS APPLIANCE MUST BE EARTHED.

All pipe work must be earthed in accordance with the current IEE

Regulations – BS 7671

After completion of all electrical works, an electrical safety check

should be carried out i.e. short circuit, earth continuity, resistance

to earth and polarity check, and all relevant test certificates pro-

duced.

Never open the front cover until all power supplies to the boiler

have been disconnected.

ELECTRICAL CONNECTIONS

The boiler connections are clearly marked inside the boiler.

L N (24hr LIVE)

The 24hr live is the permanent live connection to the boiler from

the mains supply. External controls will require an independent

fused spur supplied from the consumer unit.

Boiler Protection

The recommended protection for hard wired boilers are as fol-

lows:

Model No. Boiler size Protection

FUSION 14.4kW 14.4kW BOILER 80 AMP Protection

FUSION 12kW 12kW BOILER 63 AMP Protection

FUSION 9kW 9kW BOILER 45 AMP Protection

FUSION 6kW 6kW BOILER 32 AMP Protection

External controls

We recommend the use of the EHC Select 107XL Programmer

and EHC TLX 4101 room stat for heating only installations.

For Heating and Hot water installations, we recommend the use

of the EHC Select 207XL programmer and heat pack.

The heat pack will incorporate all the relevant parts to comply with

current building regulations i.e. Motorized valves to control the

heating and hot water circuits and Room and cylinder thermostats

to control the room and water temperatures. This will also provide

boiler interlock. The use of TRV’s alone will not provide boiler

interlock.

We recommend the use of TRV’s, however they must not be used

in the room that has the room thermostat fitted.

Note: this control method is to comply with current building regula-

tions provided by TACMA, the Association of Controls Manufactur-

ers.

Programmer/Stat connections

The boiler PCB has a voltage free connection for the controls

(RP). Under no circumstances should 240V be connected to the

controller block as this will damage the boiler’s PCB and Void the

Manufacturers warranty.

The stat / programmer connections are clearly marked within the

boiler.

Only after all connections have been made and checked should

the system be filled with water and set to the proper pressure 1.5

bar (Sealed systems).

Check the system for leaks. If water leaks into the boiler this may

damage the boiler electrics and the manufacturers warranty will

be invalid.

Under no circumstances should the boiler be switched on when

the system is dry.

The boiler has an inbuilt flow sensor. If the boiler has been

switched on with a low or no water content, the system flow

meter will sense this and prevent the boiler from sending power

to the main elements.

After the system has been filled with water and has had a cold

flush the Fernox cleanser should be added, the system filled with

water, purged of air and set to the correct pressure 1.5 bar (sealed

systems). At this point the main power may be switched on.

At this stage you may carry out the cleansing and protection of

the system. Refer to the installation section. (See page 5).

After the cleansing and protection of the system has been done,

set the external controls to the customers selected times.

If an off-peak electric meter has been installed by an Electricity

Company to supply OFF-peak rate electricity at selected times,

the appropriate settings should be entered into to the system pro-

grammer to take advantage of the OFF-peak rate electricity.

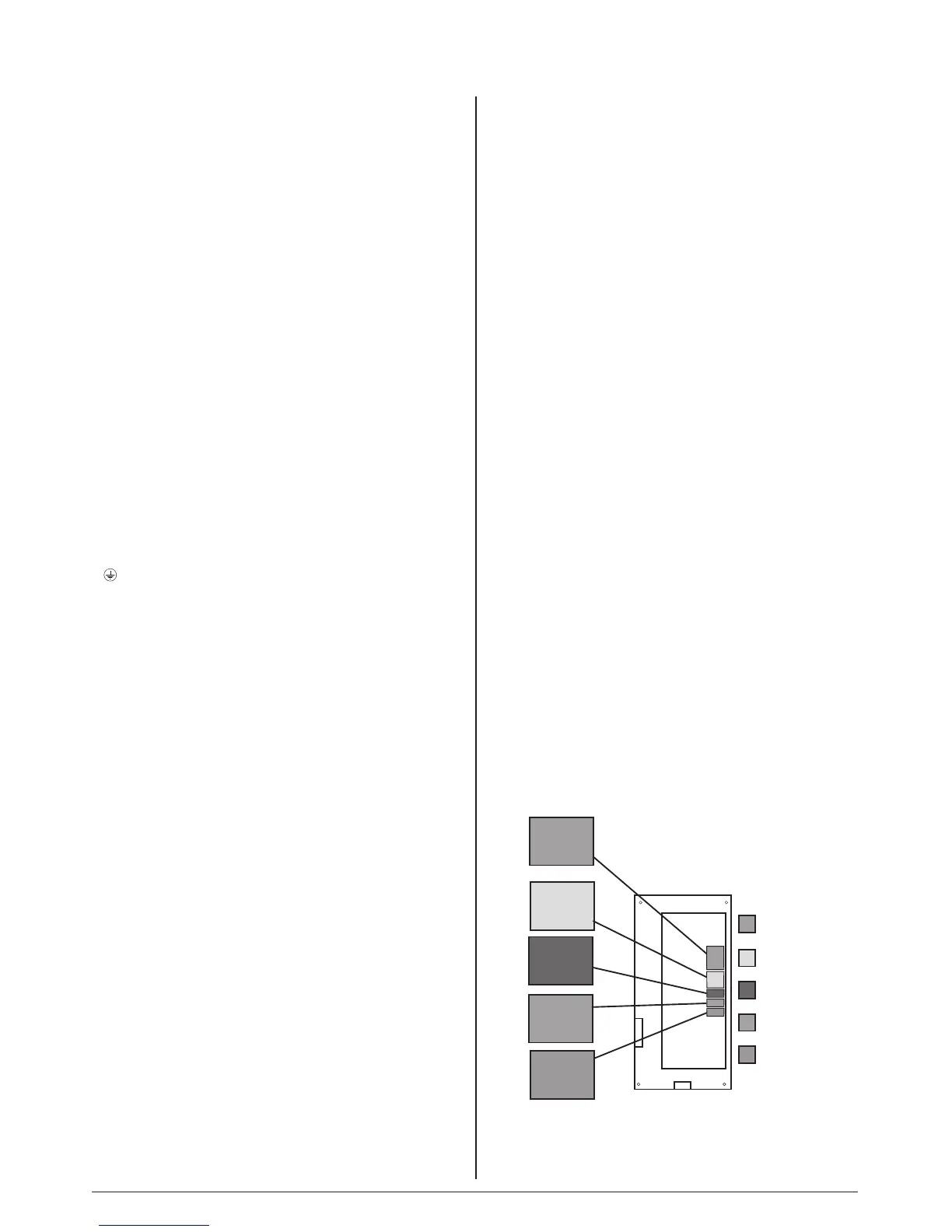

ELECTRICAL CONNECTIONS AND CONTROLS

CONTROL PANEL WIRING CONNECTIONS

To main

control

board

Flow sensor

Outlet ow

sensor

connection

Inlet return

sensor

connection

Volt free

control

connection

To main control board

Flow sensor

Outlet ow sensor

connection

Inlet return sensor

connection

Volt free control

connection

UNDER NO CIRCUMSTANCES

SHOULD A VOLTAGE BE

TAKEN TO THE NA OR RP

CONNECTION AS THIS WILL

DAMAGE THE CONTROL

PCB AND INVALIDATE THE

WARRANTY

Q

Tout

Tin

NA

Loading...

Loading...