_TECNOEKA Srl___________________________________________________________ use and instruction manual _

_ page 10 _________________________________________________________________________________________

3.

3. 3.

3. START

STARTSTART

START-

--

-UP

UP UP

UP (for installation technician)

(for installation technician)(for installation technician)

(for installation technician)

3.1

3.1 3.1

3.1 Check of nominal thermal capacity

Check of nominal thermal capacityCheck of nominal thermal capacity

Check of nominal thermal capacity

The nominal thermal capacity must be verified by an authorised technician or by the gas

supply Body, observing the information in this use manual. This check must be performed for

new installations, adaptation to another type of gas and during all extraordinary maintenance

jobs.

There is no other possibility of adjusting the nominal thermal capacity – this is done by

measuring correct connection pressure and checking if the injector being used is of appropriate

diameter. The nominal thermal capacity is controlled by using a gas meter and a chronometer.

The exact volume of gas that must flow through per time unit can be obtained from the

technical specifications table. This value must be maintained in the specified range, the

permissible tolerance being ±5%.

3.2

3.2 3.2

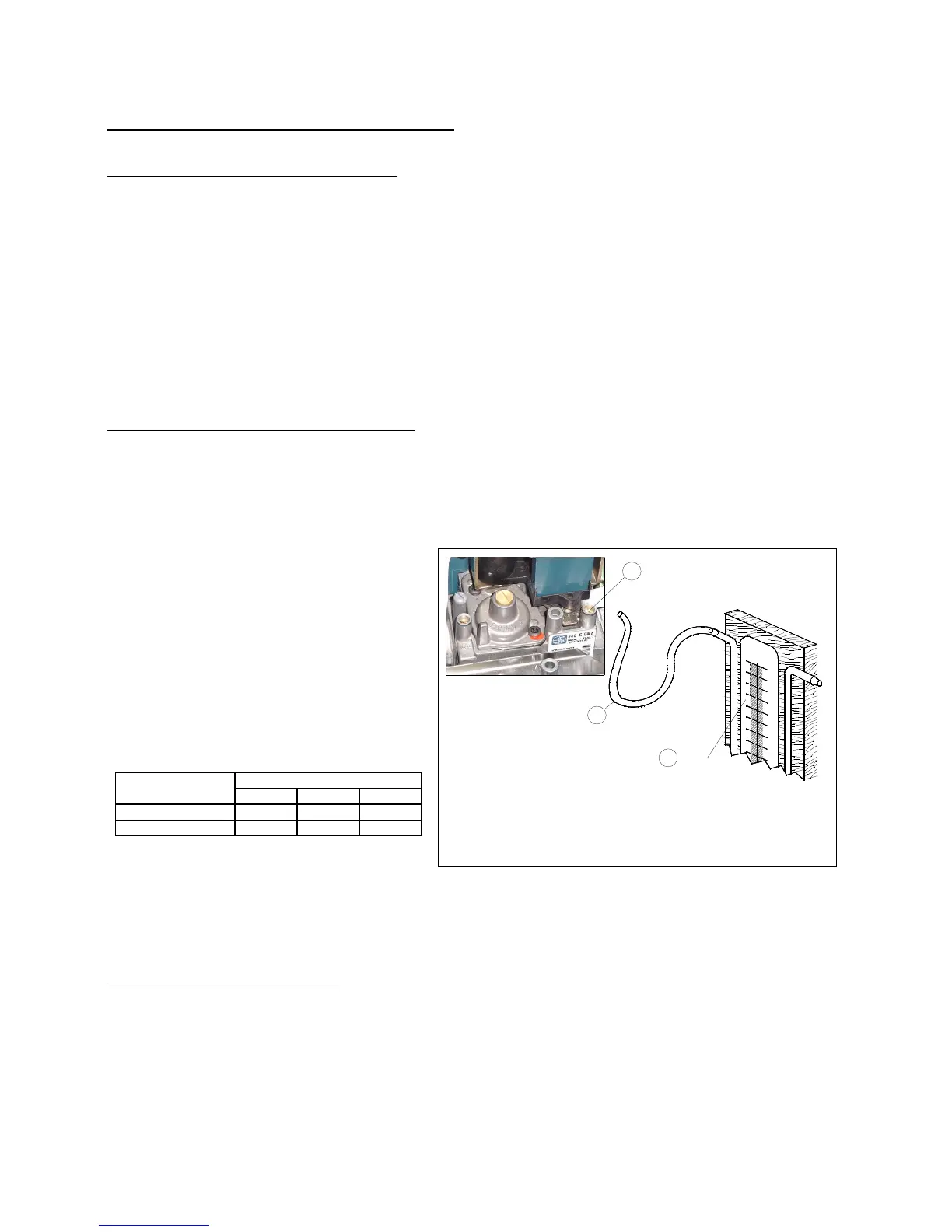

3.2 Check of connection pressure (Fig. 5)

Check of connection pressure (Fig. 5)Check of connection pressure (Fig. 5)

Check of connection pressure (Fig. 5)

Connection pressure is measured while the appliance is operating, using a pressure

measuring device for liquids (for example, a “U” pressure gauge with minimum resolution of

0.1 mbar). Control procedure: connect the hose ”T” of the pressure gauge “M” to the pressure

take-off at entry “P” of the gas solenoid-valve after removing the door on the right of the oven

and the tightness screw of the pressure take-off.

this value is not in the range shown in

table 2 and it cannot be brought within

these values by adjusting the pressure

reducers of the gas supply system,

definitive start-up of the appliance is

quite impossible.

The gas supply Body must be

informed about this.

..

.

Type of gas

Type of gasType of gas

Type of gas

G

GG

Gas

asas

as

pressure

pressurepressure

pressure

(mbar)

(mbar)(mbar)

(mbar)

Normal

NormalNormal

Normal

Minimum

MinimumMinimum

Minimum

Key

KeyKey

Key:

::

:

T =

T = T =

T = Hose

HoseHose

Hose

M = “U”

M = “U”M = “U”

M = “U”

pressure gauge

pressure gaugepressure gauge

pressure gauge

P =

P = P =

P = Pressure take

Pressure takePressure take

Pressure take-

--

-off at entry

off at entry off at entry

off at entry of gas solenoid

of gas solenoidof gas solenoid

of gas solenoid-

--

-valve

valvevalve

valve

Fig. 5

Fig. 5Fig. 5

Fig. 5

After you have measured the connection pressure, disconnect the hose “T” and screw the

tightness screw of the pressure take-off “P”.

3.3

3.3 3.3

3.3 Adaptation to other gasses

Adaptation to other gassesAdaptation to other gasses

Adaptation to other gasses

To adapt the oven to a type of gas that differs from the one tested in the factory (see

technical data plate), replace the injector of the main burner and adjust primary air inflow with

the adjustment bush. To do this, cut off electrical power and remove the door on the right of

the oven in order to facilitate access to the burner and to the primary air adjustment device. If

you do not have the necessary spare parts, contact the manufacturer’s technical assistance

service. Adaptation must be effected by qualified personnel. Consult the technical specifications

in table 1 and 3, and then replace the main injector and adjust primary air.

Loading...

Loading...