40

6. As soon as refrigerant in sight glass has gone down

to predetermined level, close charging cylinder valve.

WARNING: DISCONNECT THE CHARGING

CYLINDER HEATER AT THIS TIME TO

PREVENT THE CYLINDER PRESSURE FROM

EXCEEDING ITS MAXIMUM LIMITS.

7. Allow system to sit for five minutes.

8. Turn on refrigerator compressor. Run compressor

for few minutes and monitor system pressures.

9. When satisfied that unit is operating correctly,

clamp high-side process tube with pinch-off tool

while unit is still running.

10. Slowly open high-side manifold gauge valve to

allow compressor to remove any refrigerant trapped

in high-side hose and process fitting.

11. Close both manifold gauge valves. Ifhigh-side

gauge reading rises, pinch-off must be corrected

before proceeding.

12. Remove high-side process tube adaptor and solder

process tube closed.

13. Clamp low-side process tube with pinch-off tool

while unit is running. Remove low-side process tube

adaptor and solder process tube closed.

14. Check process tubes for refrigerant leaks.

FINAL LEAK TEST

1. With refrigerator turned OFF, leak test all low-side

system components.

2. Turn unit ON and run until condenser is warm. Leak

test high-side system components.

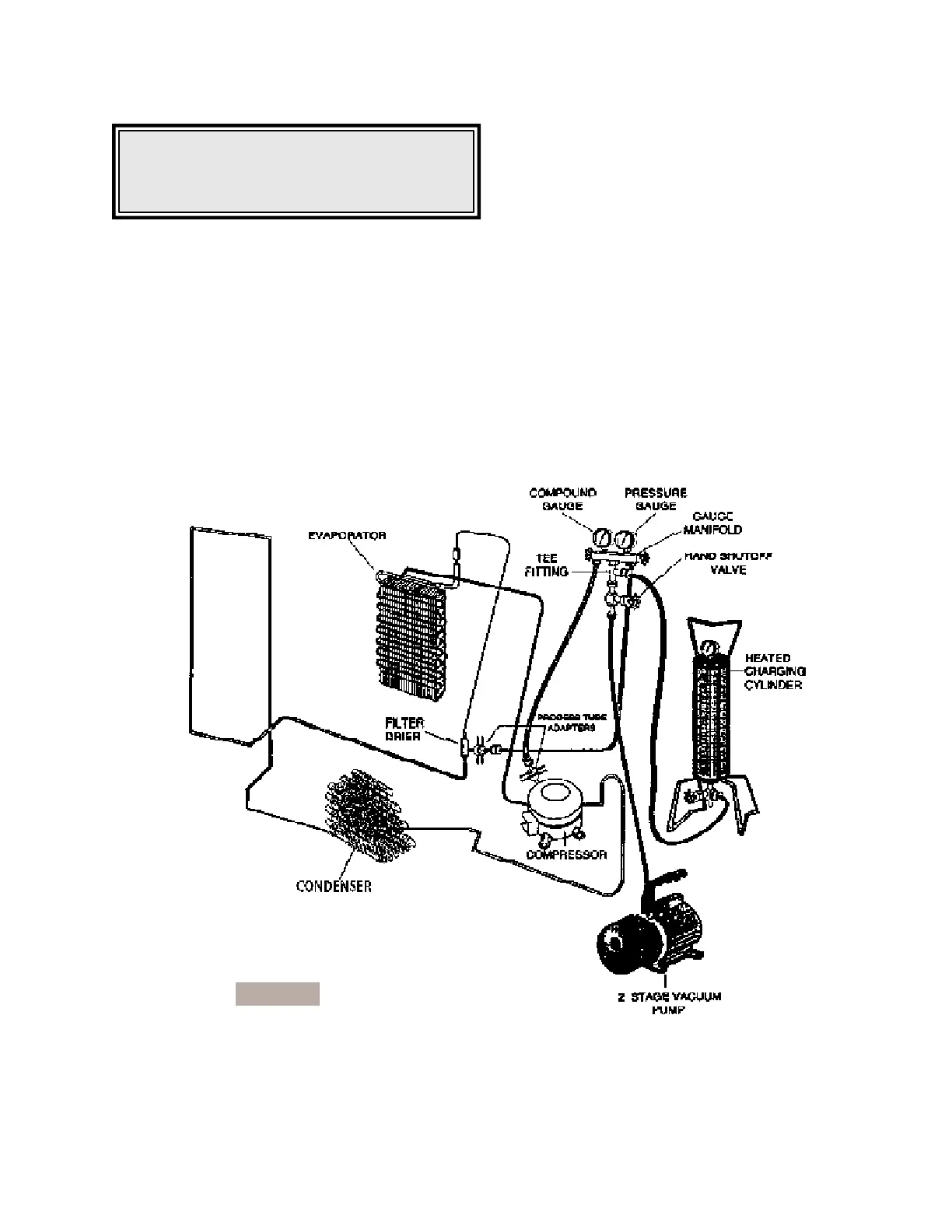

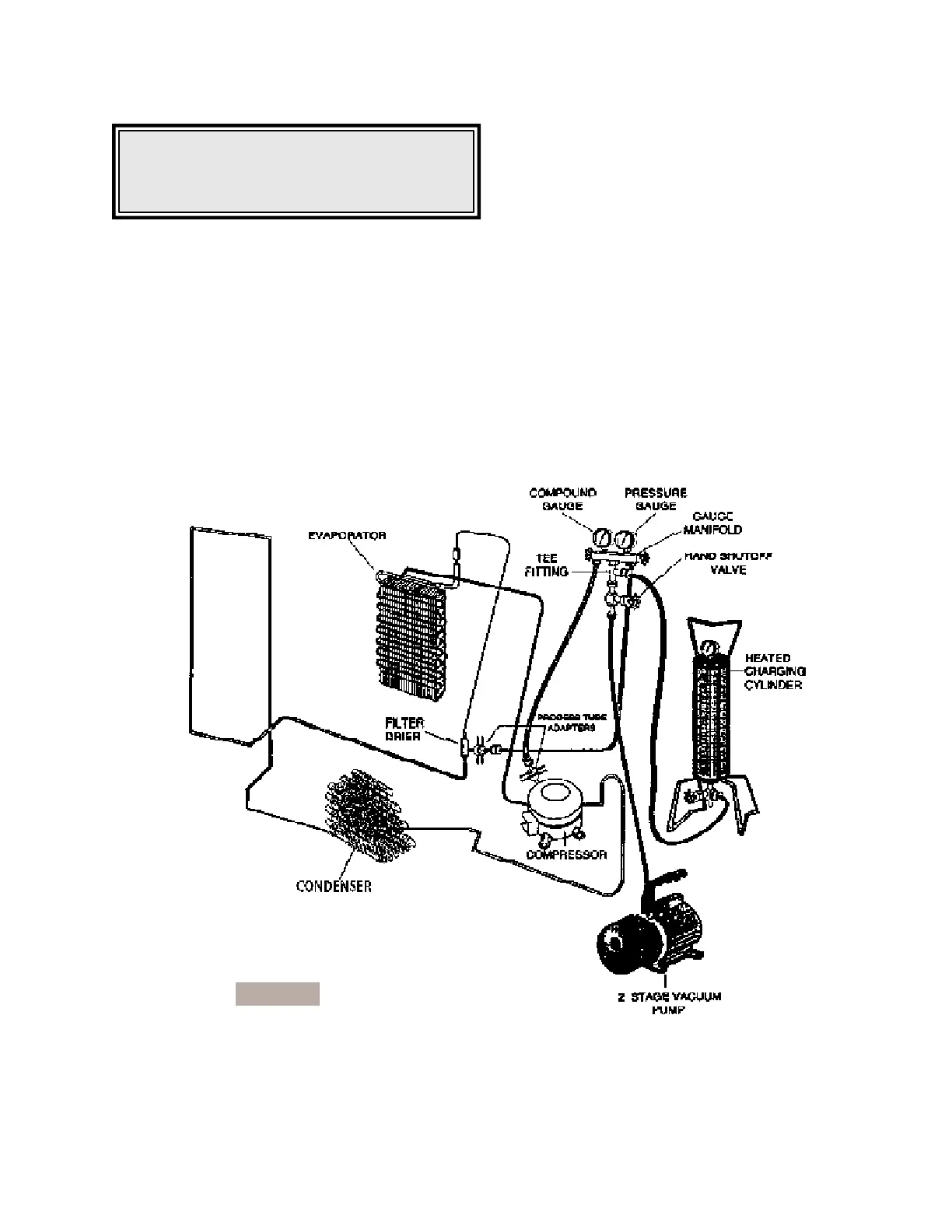

Figure E2

Loading...

Loading...