IMPORTANT

Afterservicing,completetherelevantService•

IntervalRecordsectionoftheBenchmark

Checklistlocatedonpage22and23ofthis

document.

Servicingshouldonlybecarriedoutby•

competent persons in the installation and

maintenanceofunventedwaterheating

systems.

AnysparepartsusedMUSTbeauthorised•

parts.

Disconnecttheelectricalsupplybeforeremoving•

anyelectricalequipmentcovers.

NEVERbypassanythermalcontrolsoroperate•

systemwithoutthenecessarysafetyvalves.

Watercontainedinthecylindermaybevery•

hot,especiallyfollowingathermalcontrolfailure.

Cautionmustbetakenwhendrawingwaterfrom

theunit.

SPAREPARTS

Afullrangeofsparepartsareavailableforthe

cylinderrange(Table5Page18).Refertothe

technicaldatalabelontheunittoidentifythemodel

installedandensurethecorrectpartisordered.You

willneedtoquotetheserialnumber,whichisprinted

onthedatalabel.

FAULT FINDING

Thefaultndingchart(Table4Page17)willenable

operational faults to be identied and their possible

causesrectied.Anyworkcarriedoutonthecylinder

unvented water heater and its associated controls

MUST be carried out by a competent installer for

unvented water heating systems. In case of doubt

contact servicesupport(seecontactdetailsonback

page).

WARNING

DO NOT TAMPER WITH ANY OF THE SAFETY VALVES

OR CONTROLS SUPPLIED WITH THE CYLINDER AS

THIS WILL INVALIDATE ANY GUARANTEE.

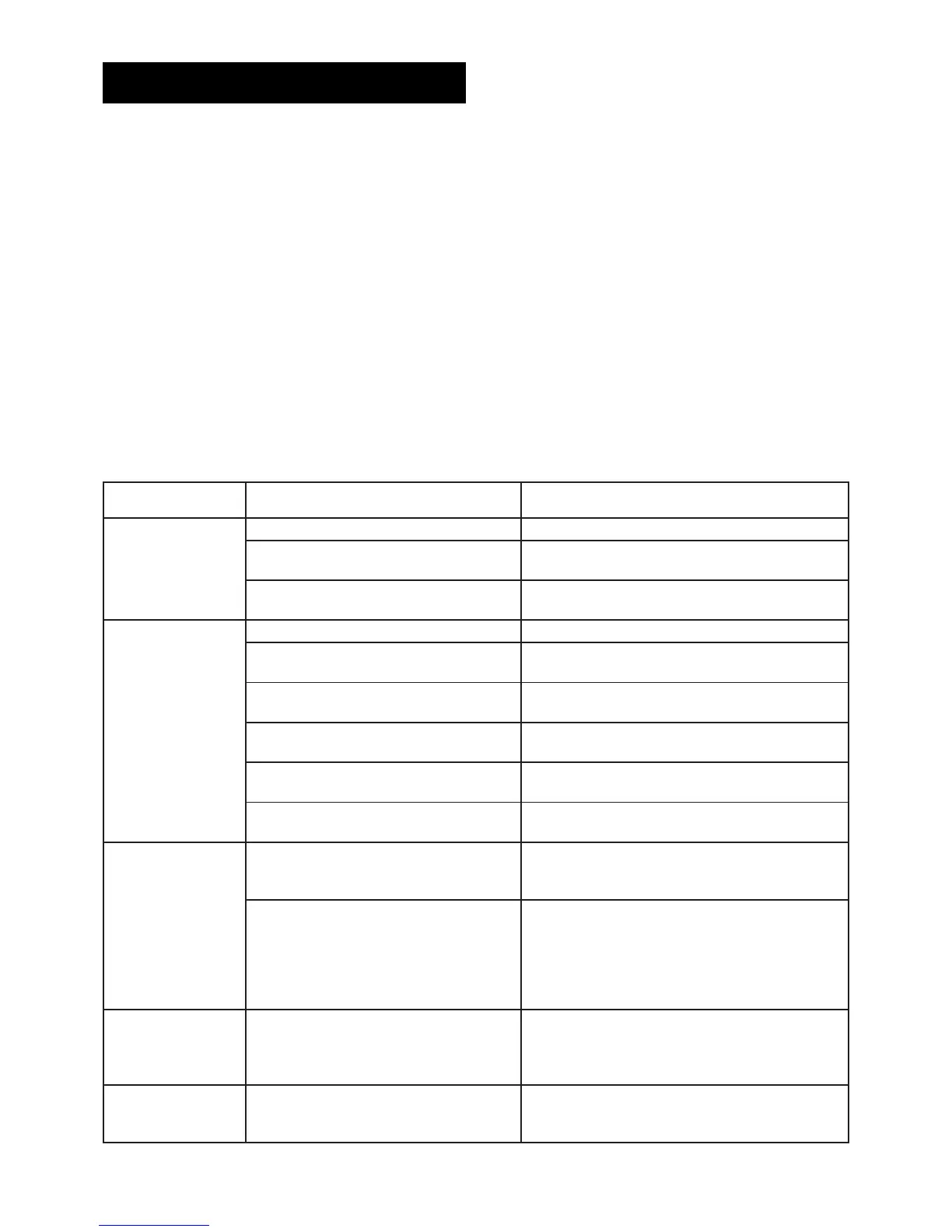

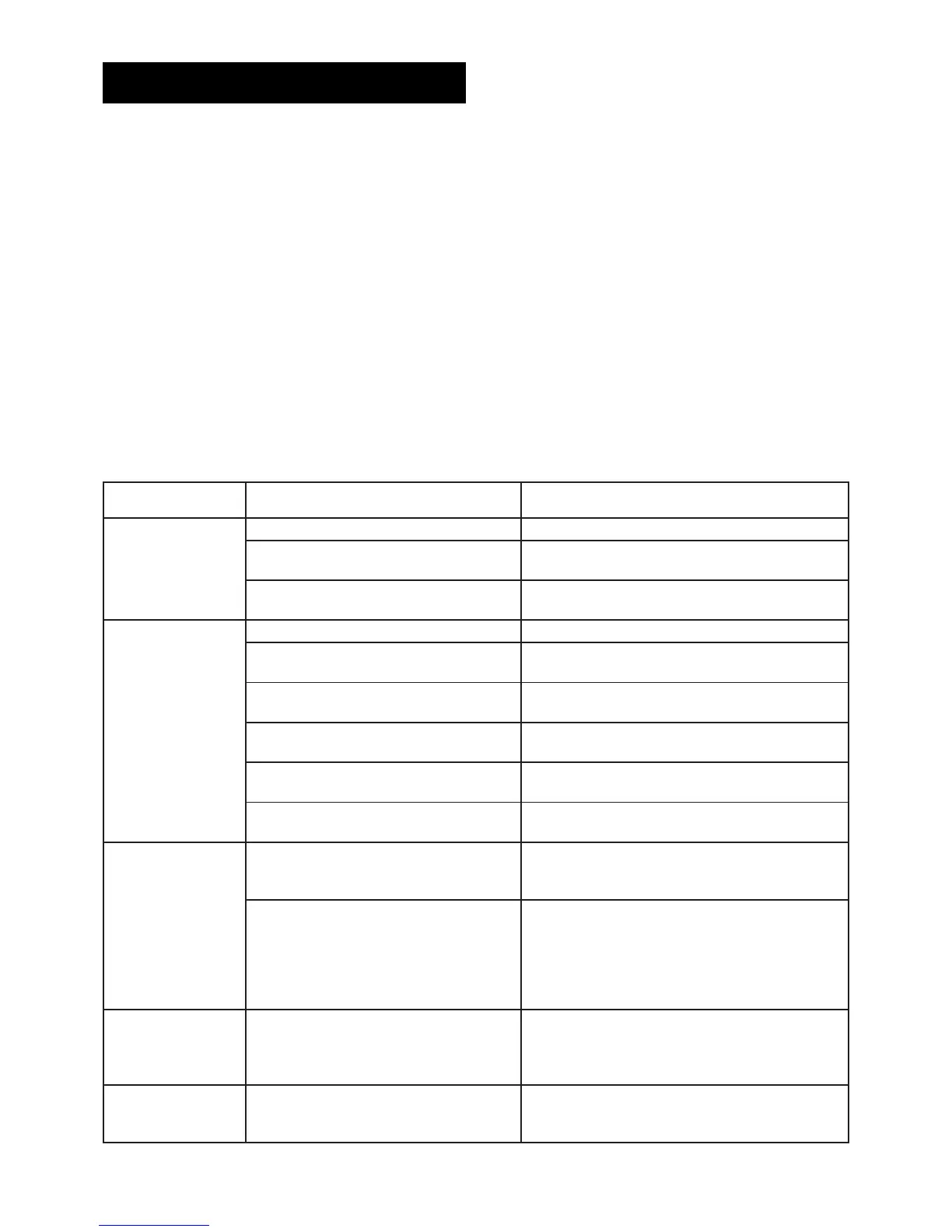

FAULT FINDING & SERVICING

Table4:FaultFindingChart

Fault Possible Cause Remedy

Nohotwaterow

Mainssupplyoff Checkandopenstopcock

Strainerblocked Turnoffwatersupply.Removestrainerand

clean

Coldwatercombinationvalveincorrectly

tted

Checkandretasrequired

Waterfromhottap

is cold

Direct immersion heater not switched on Checkandswitchon

Directimmersionheaterthermalcut-out

has operated

Check,resetbypushingbuttononthermostat

Indirect programmer set to central heat-

ing only

Check,settodomestichotwaterprogramme

Indirectboilernotworking Checkboileroperation.Iffaultissuspected

consultboilermanufacturer’sinstructions

Indirectthermalcut-outhasoperated Check,resetbypushingbuttononthermostat

Checkoperationofindirectthermostat

Indirect motorised valve not connected

correctly

Checkwiringand/orplumbingconnectionsto

motorised valve

Waterdischarges

fromexpansion

valve

INTERMITTENTLY

Expansion vessel charge pressure has

reducedbelow3.5bar,orsettohigh

SeeMaintenancesectionforre-chargingof

expansion vessel procedure

CONTINUALLY

coldwatercombinationvalvepressure

reducernotworkingcorrectly.

Expansion valve seat damaged

Checkpressurefromcoldwatercombination

valve.Ifgreaterthan3.5barreplacepressure

reducing valve

Removeexpansionvalvecartridge,check

conditionofseat.Ifnecessarytnewexpansion

valve

Waterdischarges

fromT&Prelief

valve

Thermalcontrolfailure

NOTE: water will be very hot

Switchoffpowertoimmersionheater(s)and

shutdownboiler.

DO NOTturnoffwatersupply.Whendischarge

stopscheckallthermalcontrols,replaceiffaulty

Milkywater

Oxygenated water Waterfromapressurisedsystemreleases

oxygenbubbleswhenowing.Themilkinesswill

disappearafterashortwhile

Loading...

Loading...