4

6

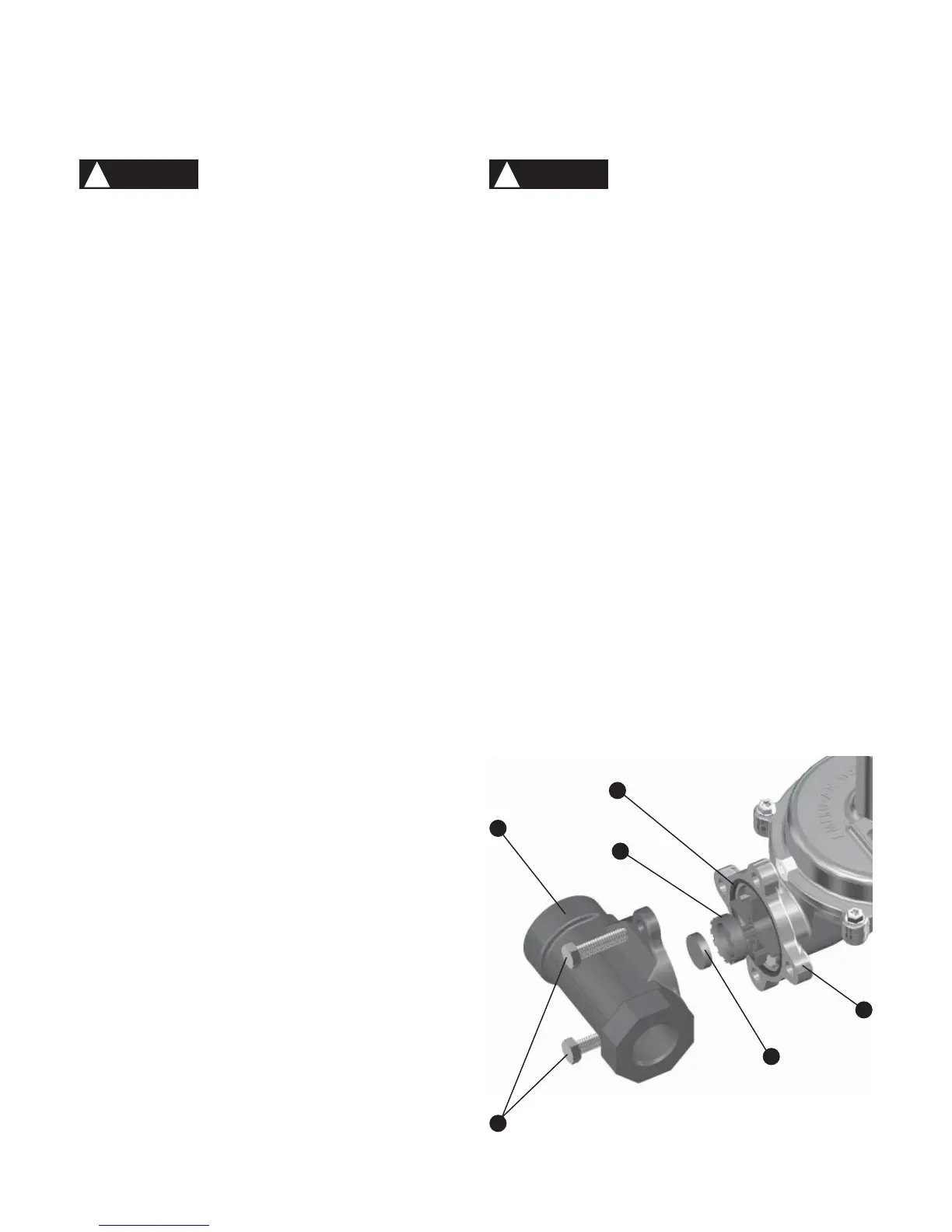

Figure 3

2

3

1

5

As a knowledgeable user of Elster American

Meter Company products, you should be

aware that parts in the Company's meters

and regulators contain, or are coated with,

heavy metals such as cadmium, zinc, lead

and chromium. Repair or refurbishment

of this equipment should take into account

the presence of these materials and should

comply with all state and federal requirements

concerning worker protection, proper disposal,

and safety including protection against exposure

to dust and fumes.

SR100 Series Service Regulators 05 Elster American Meter

Inspection of Valve Seat Disc and Orifice

(Numbers in parentheses refer to Figure 3.)

Shut off gas supply and depressurize the system.1.

Remove two valve body bolts (2) securing the diaphragm 2.

case (3) to the valve body (1) with a 1/2" wrench. Separate

the diaphragm case from the valve body.

Visually check the seating edge of the orifice inside the 3.

valve body (1) . If it is nicked or damaged, it should be

replaced with a new orifice to provide positive shut off. See

Maintenance instructions for replacing orifice on page 6.

Inspect the surface of the valve seat disc (4). If it is scored 4.

or uneven, replace it as outlined in the Maintenance

instructions for replacing the seat disc on page 5.

Install new seal ring (5) in the diaphragm case groove.5.

Inspect unit for cleanliness and proper positioning of the 6.

parts. Pay particular attention to the proper positioning of

the seal ring (5) in the groove.

Install the diaphragm case (3) on the valve body (1). Make 7.

sure the vent is positioned so that it cannot become plugged

or allow water to enter. Replace and tighten the two valve

body bolts (2) to 100 ±25 in. lbs.

Proceed to Steps 4, 5 and 6 of the Installation instructions.8.

Regulators are pressure-control mechanisms

having numerous moving parts which can

wear. In addition, regulator damage may occur

from external sources. For these reasons, the

regulator should be periodically inspected and

checked for proper operation. The frequency

of inspection depends on the severity of the

service conditions and the requirements of

applicable local, state, and federal codes and

regulations.

Follow the procedure below for field inspection

of the orifice and seat disc. Repair parts are

available through Elster American Meter if parts

are worn or damaged. Exercise care to prevent

foreign material from entering the regulator

during any inspection or maintenance activities.

Inspection Maintenance

!

CAUTION

Replacing Seat Disc

(Numbers in parentheses refer to Figure 3.)

Follow steps 1 and 2 of the Inspection instructions on page 5 1.

to access seat disc.

Carefully insert the tip of a knife along the edge of the seat 2.

disc (4) and the lift the seat disc out of the plunger (6).

Install a new seat disc (4) into the plunger (6) by pressing 3.

into place. Make sure that the disc is pressed completely

into the plunger (6).

Proceed to Steps 5, 6, 7, and 8 of the Inspection instructions 4.

on page 5.

!

CAUTION

Loading...

Loading...