EM TEST VDS 200 Series

Manual for Operation V 5.19 30 / 57

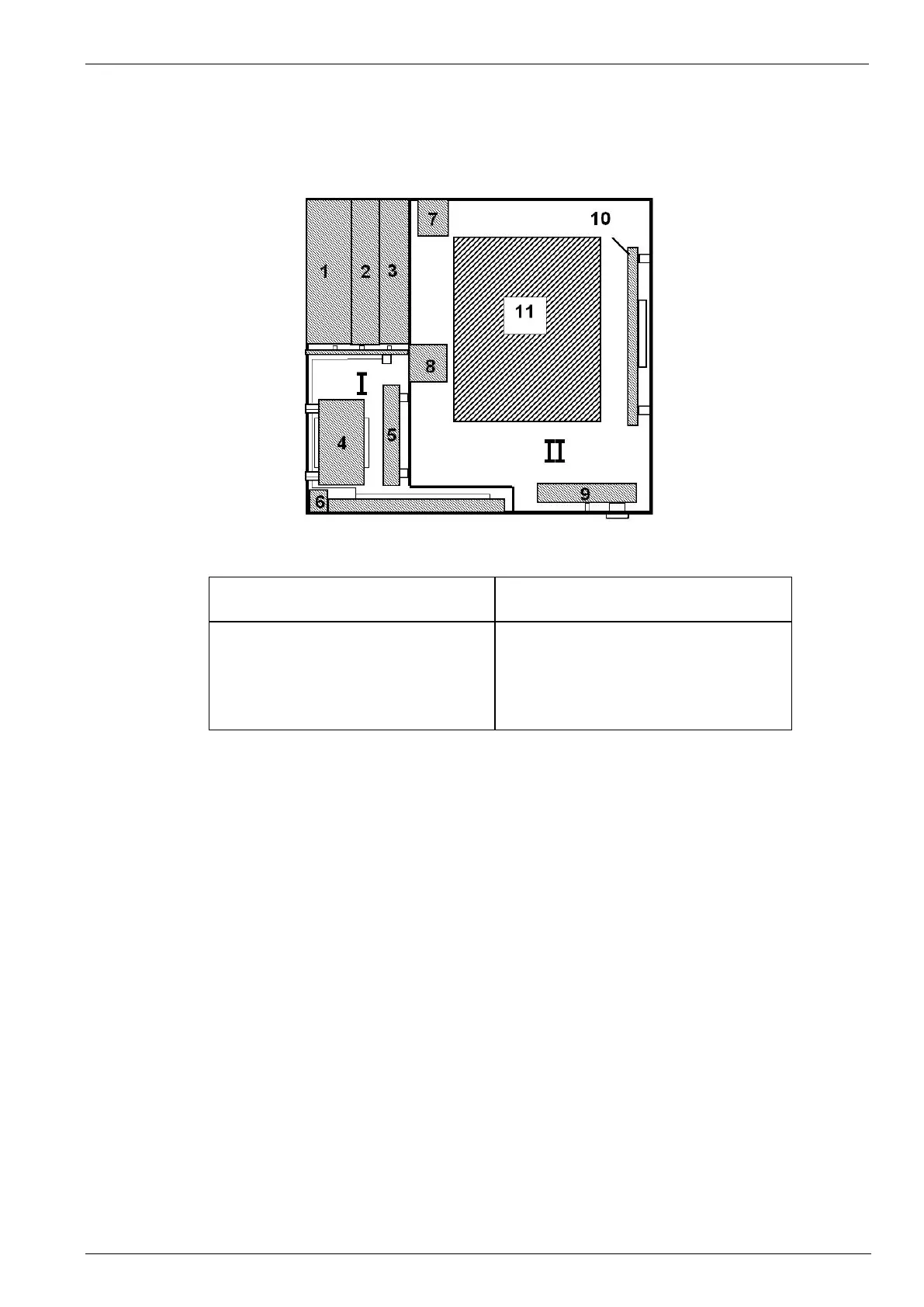

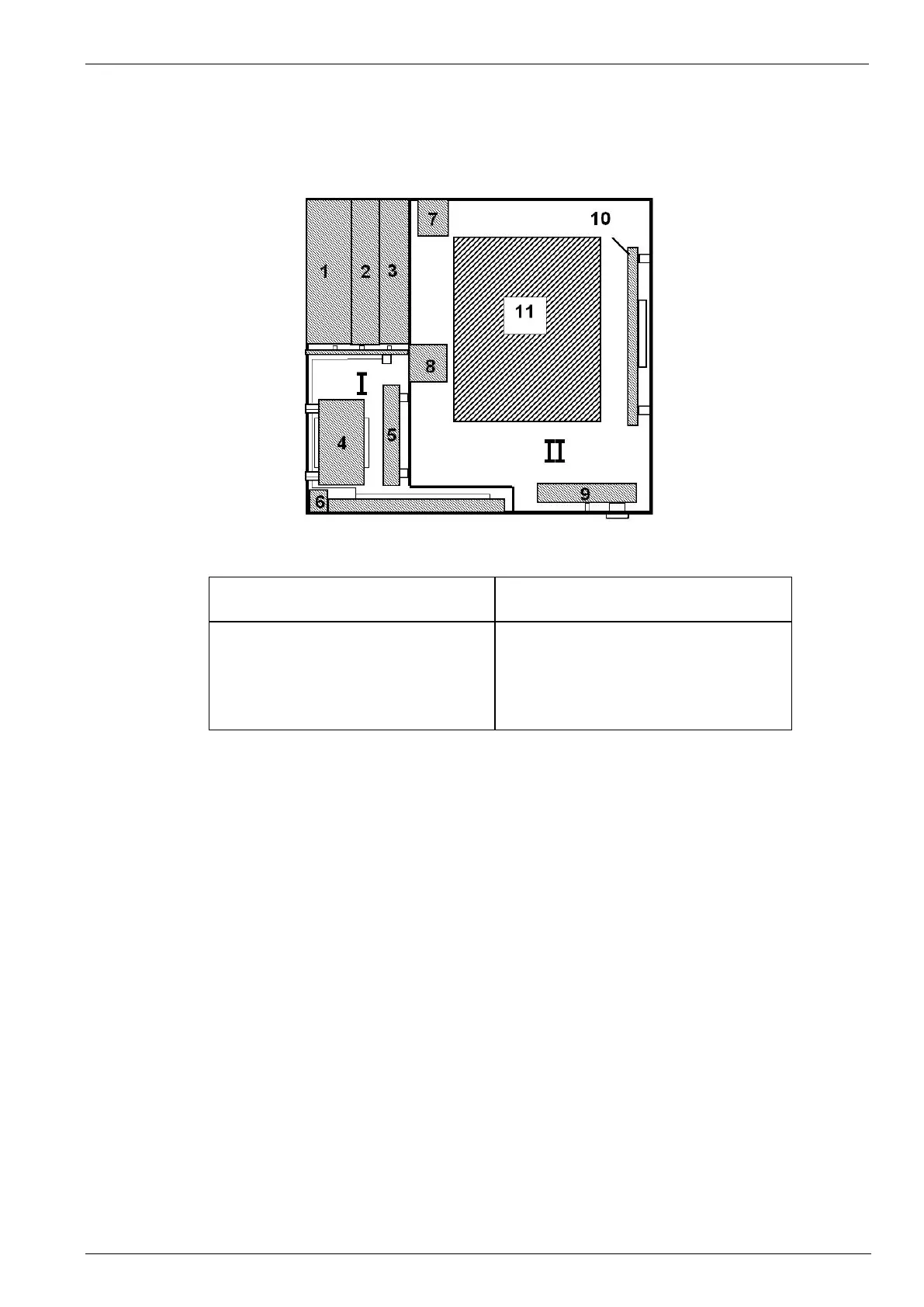

Test Equipment

Construction

The Voltage Drop Simulator VDS 200 is built in a 19" housing and is divided into two parts, the control unit and the

power electronics. The 100A type is designed in a small rack on wheels.

1 Power supply

2 Interface board

3 Processor board

4 Transformer

5 Filter board

6 Keyboard / LCD display

7 Power supply

8 Current sensor

9 Front-panel board

10 Control for Amplifier

11 Amplifier design depends on model

Control unit

The control unit is based on a microprocessor system and a driver board which includes a galvanic decoupling

between the control unit and the power electronics. The firmware for controlling the system is stored in two

EPROM’s. The control unit is built up by 3 boards, the power supply, the micro-controller board and the interface

board.

Power supply unit

The power supply unit supplies voltages of +/- 15V, + 5V, + 24V for all other modules of the simulator. The unit is

fused on the back of the device in the power supply socket.

Micro-controller unit

This unit controls the entire functions of the power supply simulator and simultaneously organizes the data

transfer via the serial RS 232 or parallel IEEE interface.

The desired test parameters are preselected via the function keys or the knob (incr./decr).

I / O Controller

All control parameters entered via the keyboard or the interfaces are interpreted by the I/O controller. In addition

this print contains the control of the power electronics as well as the optical separation between control circuits

and power electronic.

LED

Two LED’s mounted on the front panel show if a channel is active or not. The LED of an active channel is lighted.

During mode V the LED display switches from one channel to the other.

Loading...

Loading...