December 2016

26

Quick Start Guide

9. Special conditions of use

a. If the enclosure is made of an alloy or plastic material, the following

precautions must be observed:

(i) The metallic alloy used for the enclosure material may be at the

accessible surface of this equipment; in the event of rare accidents, ignition

sources due to impact and friction sparks could occur. This shall be

considered when the Rosemount 2120 is being installed in locations that

specifically require Equipment Protection Level Ga or Da [ATEX: group II,

category 1G equipment] [

IECEx: in Zone 0 and 20 locations].

(ii) Under certain extreme circumstances, the non-metallic parts

incorporated in the enclosure of the Rosemount 2120 may generate an

ignition-capable level of electrostatic charge. Therefore, when they are

used for applications that specifically require Equipment Protection Level

Ga or Da [ATEX: group II, category 1G equipment] [IECEx: in Zone 0 and 20

locations], the Rosemount 2120 shall not be installed in a location where

the external conditions are conducive to the build-up of electrostatic

charge on such surfaces. Additionally, the Rosemount 2120 shall only be

cleaned with a damp cloth.

b. Ensure the ambient air temperature (Ta) and the process temperature (Tp)

are within the range detailed above for the T class of the specific explosive

gases or vapors present.

c. Ensure the ambient air temperature (Ta) and the process temperature (Tp)

are within the range detailed above for the maximum surface temperature

of the specific explosive dusts present.

10.15 Instructions for hygienic installations

The following instructions are for a Rosemount 2120 Level Switch (“level switch”)

with 38 mm or 51 mm Tri Clamp fitting covered by 3-A authorization 3496 and

EHEDG certificate 102016, and ASME-BPE and FDA compliance:

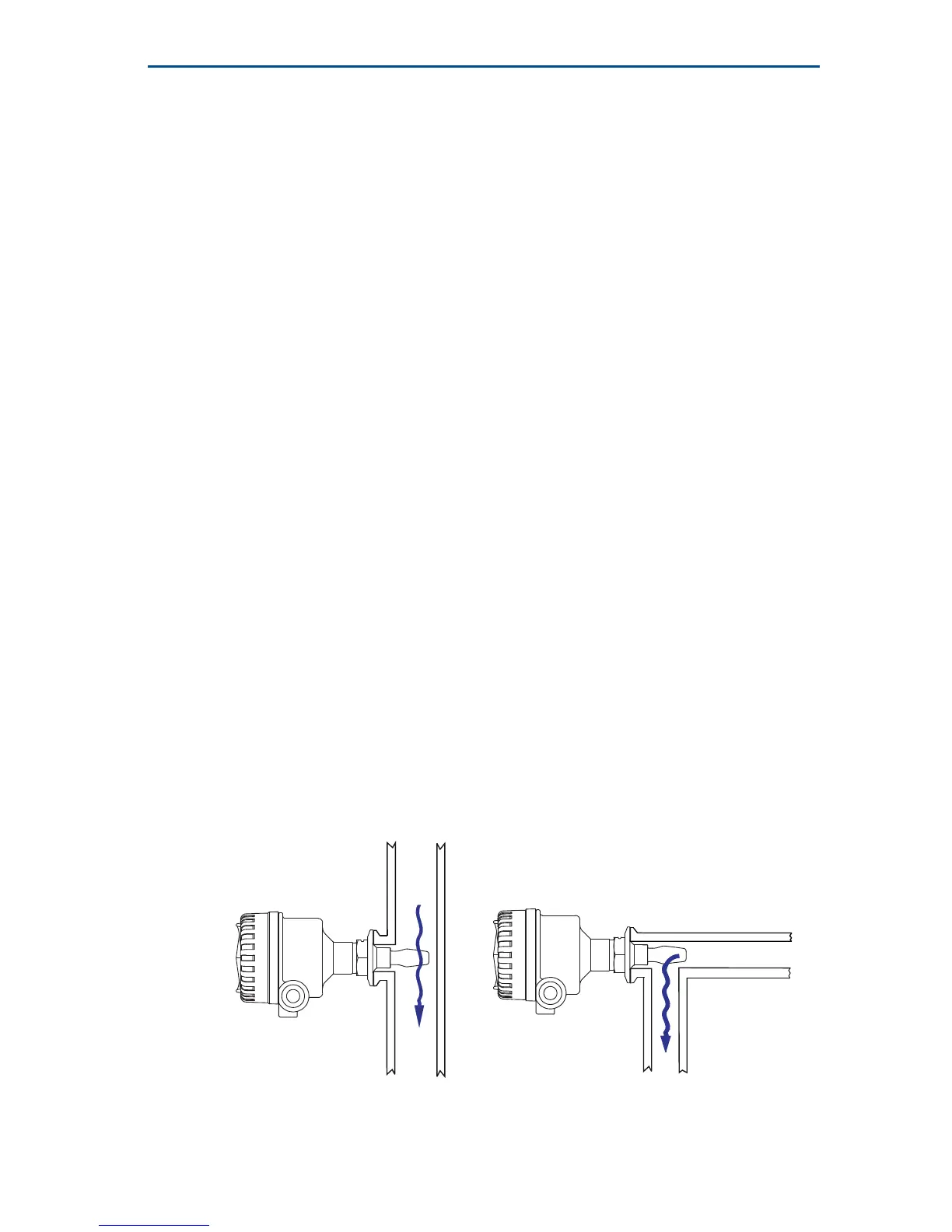

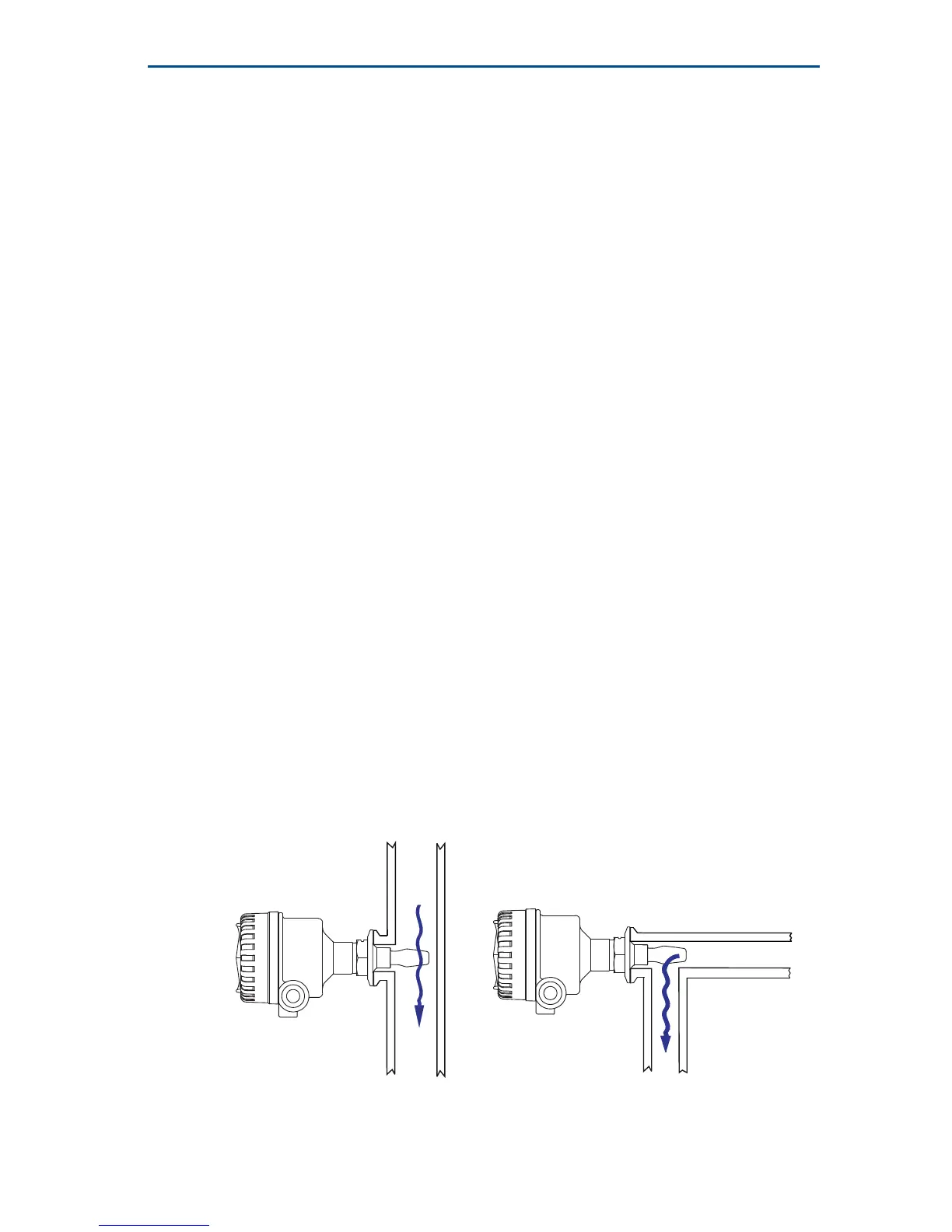

1. The level switch is suitable for installation on pipeline (with fork gap in line

with the flow) and on closed vessels (with the fork gap vertical).

EHEDG only recommend horizontal stub mounting in pipelines:

2. Installation of the level switch shall be carried out by suitably trained

personnel, in accordance with the applicable standards and code of practice.

O

Loading...

Loading...