Quick Start Guide

3

December 2016

1.0 Introduction

1.1 Rosemount 2120 overview

The Rosemount 2120 Level Switch (“level switch”) uses vibrating short fork

technology, and is suitable for virtually all liquid applications.

The level switch is designed to use the principle of a tuning fork. A piezo-electric

crystal oscillates the forks at their natural frequency (~1400 Hz). Changes to this

frequency are continuously monitored. The frequency of the vibrating fork sensor

changes depending on the medium in which it is immersed. The denser the

liquid, the lower the frequency.

When used as a low level alarm, the liquid in the tank or pipe drains down past the

fork, causing a change of natural frequency that is detected by the electronics

and switches the output state to a dry condition. When the level switch is used as

a high level alarm, the liquid rises in the tank or pipe, making contact with the fork

which then causes the output state to switch to a wet condition.

The level switch has a ‘heartbeat’ LED that indicates its operating state. The LED

flashes when the switch output is ‘off’ and is constantly lit when 'on'.

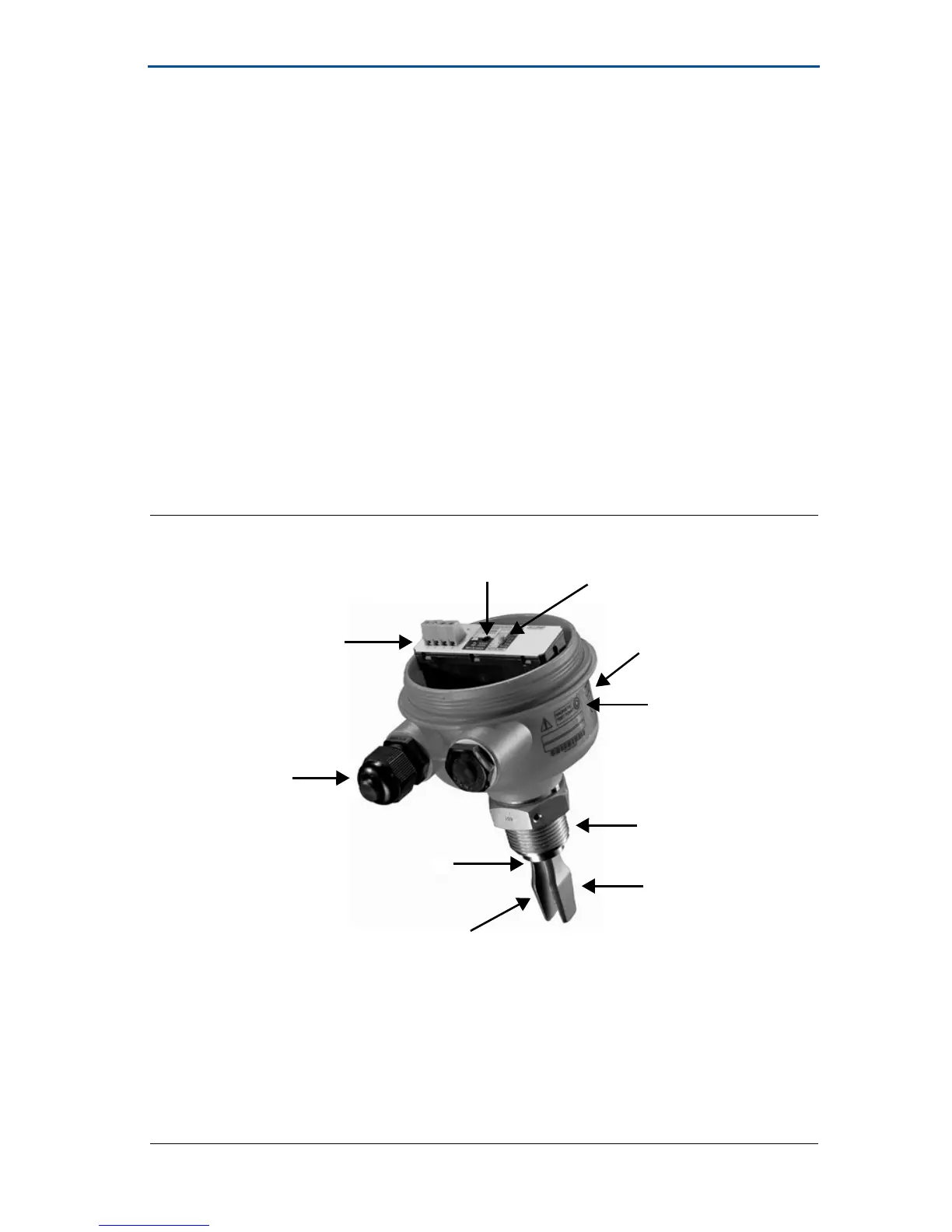

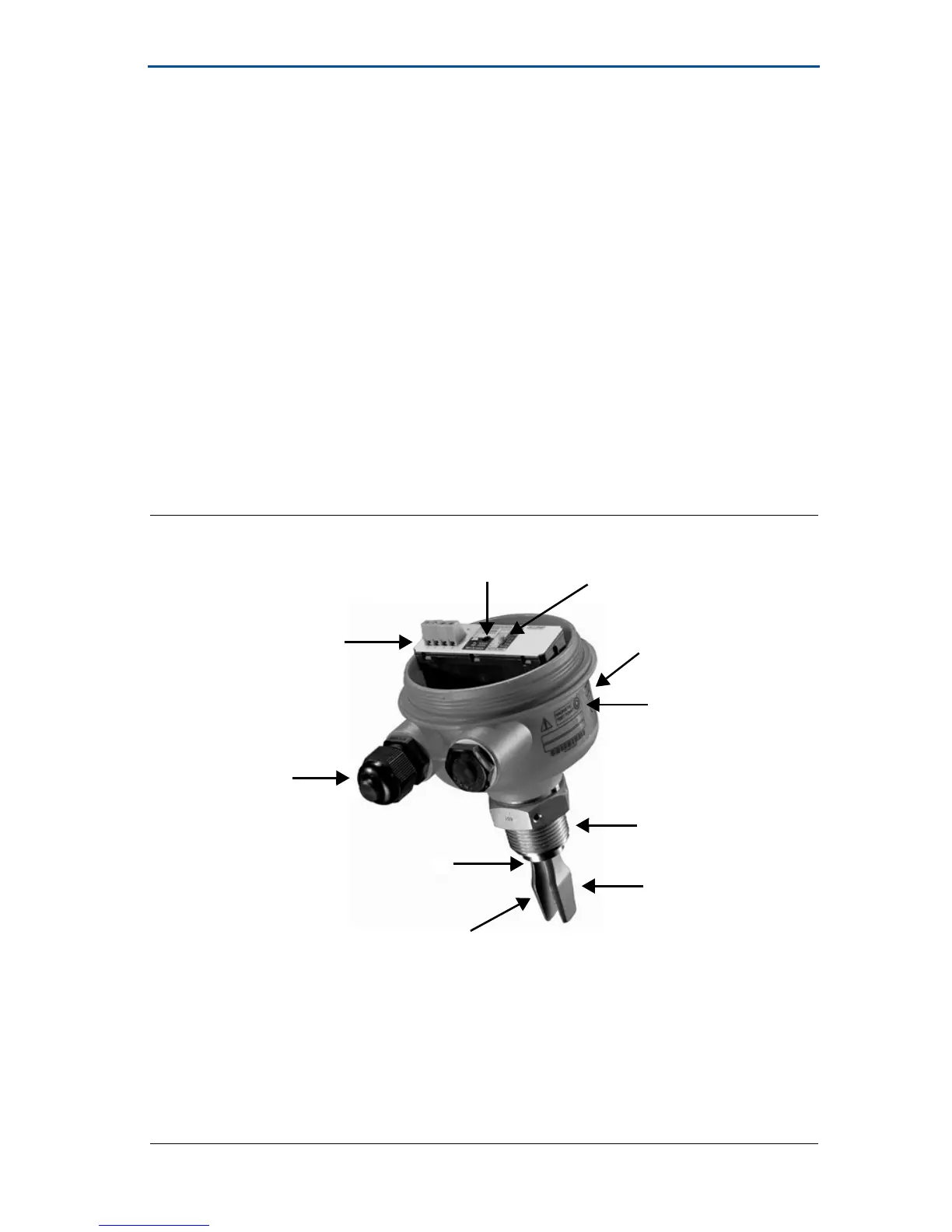

Figure 1. Rosemount 2120 Features

A. Visible ‘heartbeat’ LED G. Wetted material in 316/316L SST, solid

B. Mode switch and adjustable time delay Alloy C and Alloy C-276, or

C. Housings in glass-filled nylon, ECTFE-coated 316/316L SST

aluminum, or 316 SST H. Short fork length or extensions up to

D. Magnetic test point 157.5-in. (4 m)

E. Threaded, flanged, or hygienic connections. I. Two cable/conduit entries

F. ‘Fast drip’ fork design J. Direct Load, Relay DPCO, PLC/PNP,

NAMUR, or 8/16 mA electronics

Loading...

Loading...