13

15°

45°

D 3.453 3.453 3.453 3.453 3.453 3.675 3.675 3.675 4.796

E 3.453 3.453 3.453 3.453 3.453 3.675 3.675 3.675 4.796

F 4.013 4.013 4.013 4.013 4.013 4.013 4.013 4.013 4.633

G 3.763 3.763 3.763 3.763 3.763 3.763 3.763 4.763 4.763

H 3.889 3.889 3.889 3.889 4.826 4.826 4.826 4.826 -

2J3 4.326 4.326 - - - - - - -

2½J4 - - 4.357 4.357 5.107 5.107 - - -

3J4 - - 6.232 6.232 6.232 6.232 6.441 6.441 -

K 4.701 4.701 4.701 4.701 5.826 5.826 7.013 7.013 -

L 5.045 5.045 5.263 5.263 5.263 6.236 6.236 6.236 -

M 5.576 5.576 5.576 5.576 5.576 6.389 6.389 - -

N 6.117 6.117 6.117 6.117 6.117 - - - -

P 5.857 5.857 7.607 7.607 7.607 - - - -

Q 7.732 7.732 7.732 7.732 7.732 - - - -

R 8.117 8.117 8.117 8.117 8.117 - - - -

T, T2 9.576 9.576 9.576 - *9.576 - - - -

'A'

0.332 0.370 0.369 0.398 0.429 0.531 0.546 0.605 0.632 0.692 0.783 0.781 0.839

'B'

0.021 0.025 0.030 0.036 0.044 0.051 0.063 0.070 0.076 0.091 0.118 0.139 0.176

0.023 0.027 0.032 0.038 0.046 0.053 0.065 0.072 0.078 0.093 0.120 0.141 0.178

CROSBY STYLE JOS-E, JBS-E, JLT*-JBS-E, JLT*-JOS-E VALVES

InstallatIon and MaIntenance InstructIons

6.5.2

Machining of nozzle seats

If machining of the nozzle seat or

other major repairs are necessary, it is

recommended that the valve be returned

to a Emerson facility for repair. All

parts must be machined accurately per

Emerson specifications.

No pressure relief valve will be tight,

nor will it operate properly unless all

parts are machined correctly. The most

satisfactory way to machine a nozzle is to

remove it from the valve body. However,

it may also be machined while assembled

within the valve body. In any event, it is

vitally important that the seating surfaces

run absolutely true before machining.

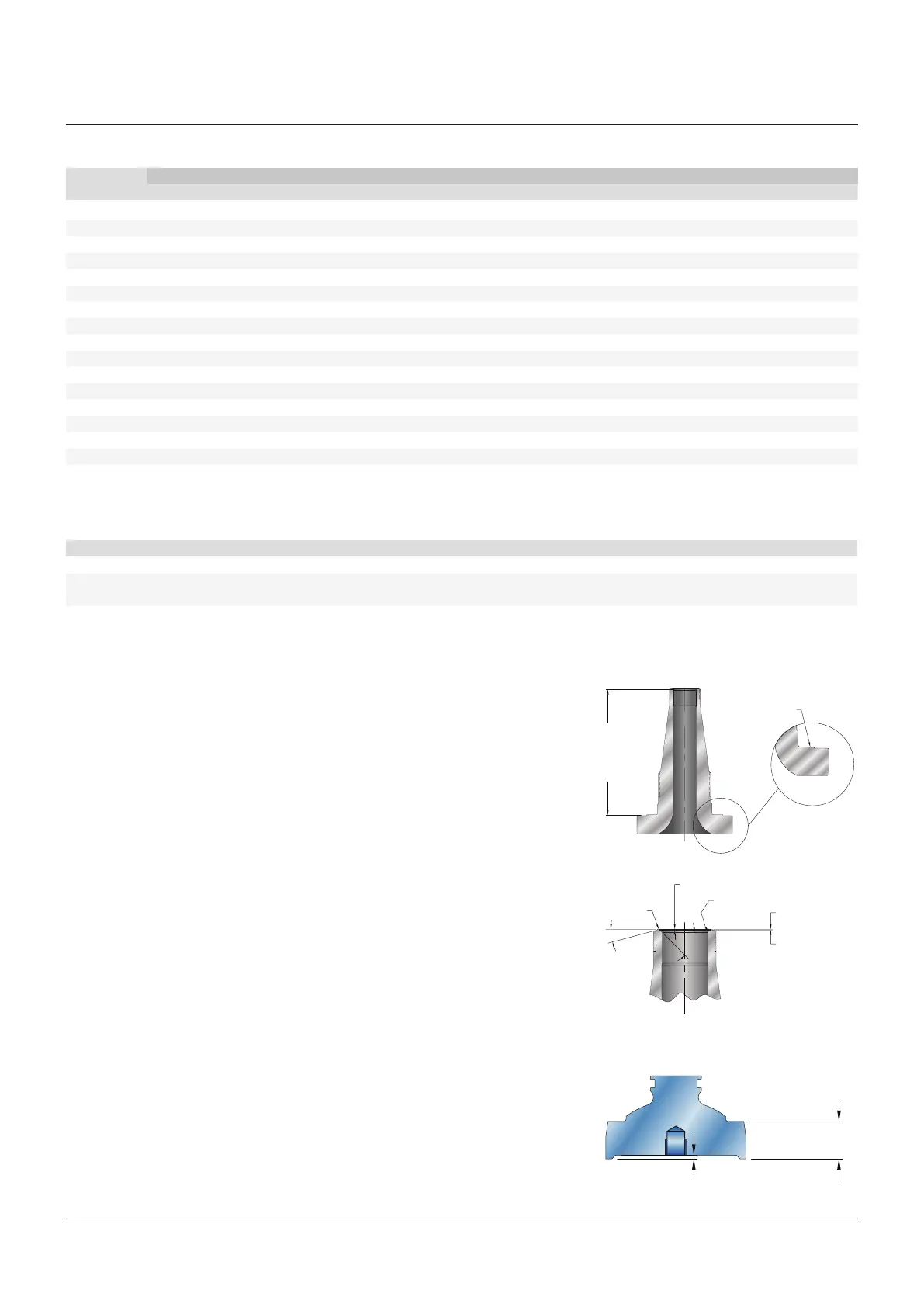

FIGURE 10

Nozzle seat critical dimensions

Minimum

face to

seat dim,

refer to

Table 8

Raised seal face

Related

surfaces

Seat

0.010-0.014

machined

0.008 min after

lapping

0.004 after lapping

* Type 42, 44 not available

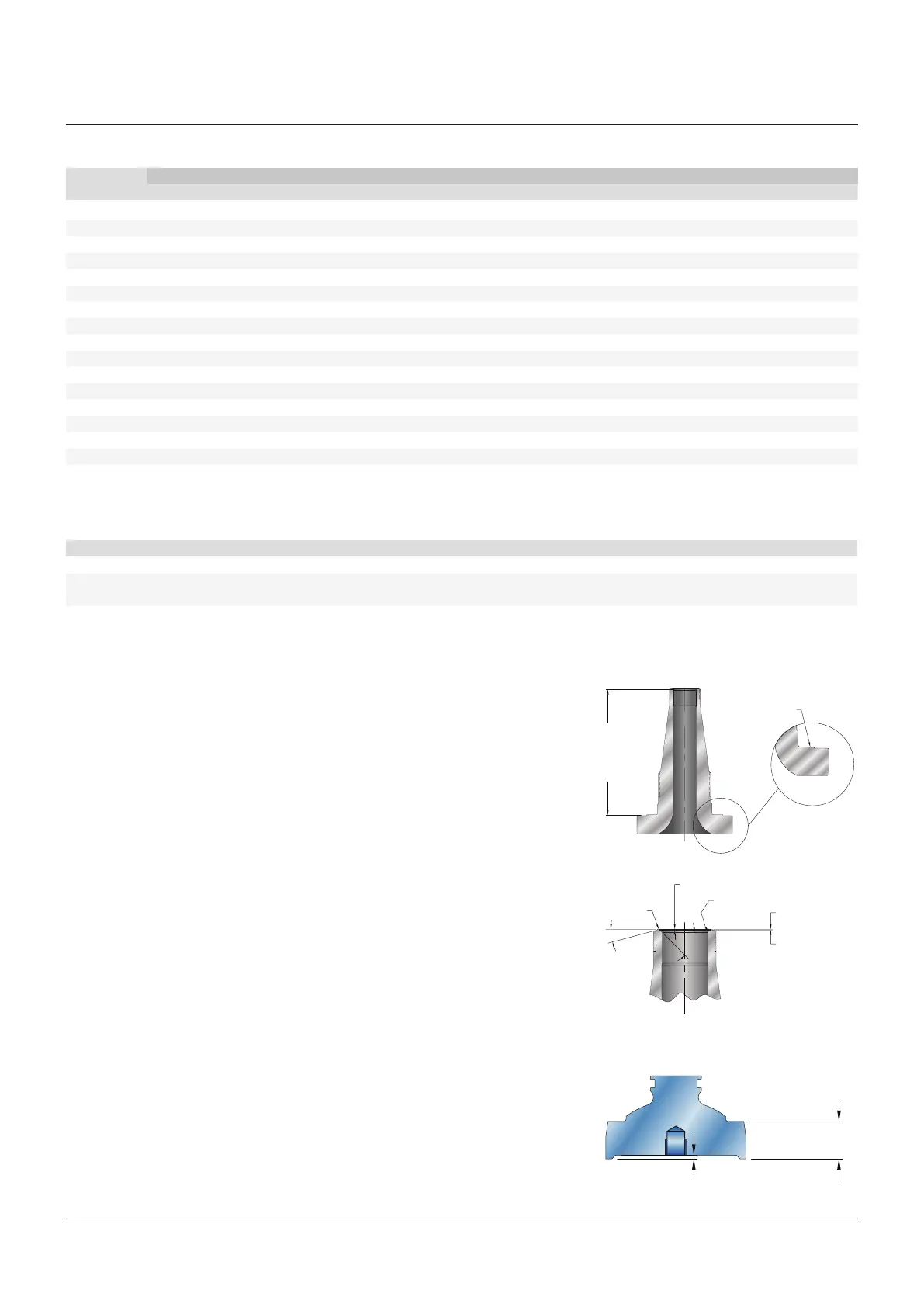

6.5.3 Machining of disc insert seats

When the damage to the disc insert seat

is too severe to be removed by lapping,

the disc insert may be machined and

lapped provided that minimum seat height

is maintained (Figure 11 and Table 9).

FIGURE 11

Disc insert minimum seat height (Table 9)

'B' mach.

'A' min.

after lapping

TABLE 9 - Disc insert minimum seat heights

Orifice

D and E

F G H J K L M N P Q R T

TABLE 8 - Minimum nozzle face to seat dimensions (see Figure 10)

Valve type

Orifice 12, 14, 15, 16 22, 24, 25, 26 32, 34, 35, 36, 37 47 42, 44, 45, 46 57 55, 56 64, 65, 66, 67 75, 76, 77

Machining dimensions for Crosby Style

JOS-E/JBS-E valves with metal-to-metal

nozzle seats are shown in Figure 10

and Table 8. Remove only enough metal

to restore the surface to its original

condition. Turning to the smoothest

possible finish will facilitate lapping.

The nozzle must be replaced when

minimum face to seat dimension is

reached. This critical dimension is shown

in Table 8.

Loading...

Loading...