Instruction Manual

D100394X012

EH (1-1/2x1 through 8x6)

July 2017

12

When all nuts are tightened to that torque value, increase the torque by one fourth of the specified nominal torque

and repeat the crisscross pattern. Repeat this procedure until all nuts are tightened to the specified nominal value.

Apply the final torque value again and, if any nut still turns, tighten every nut again.

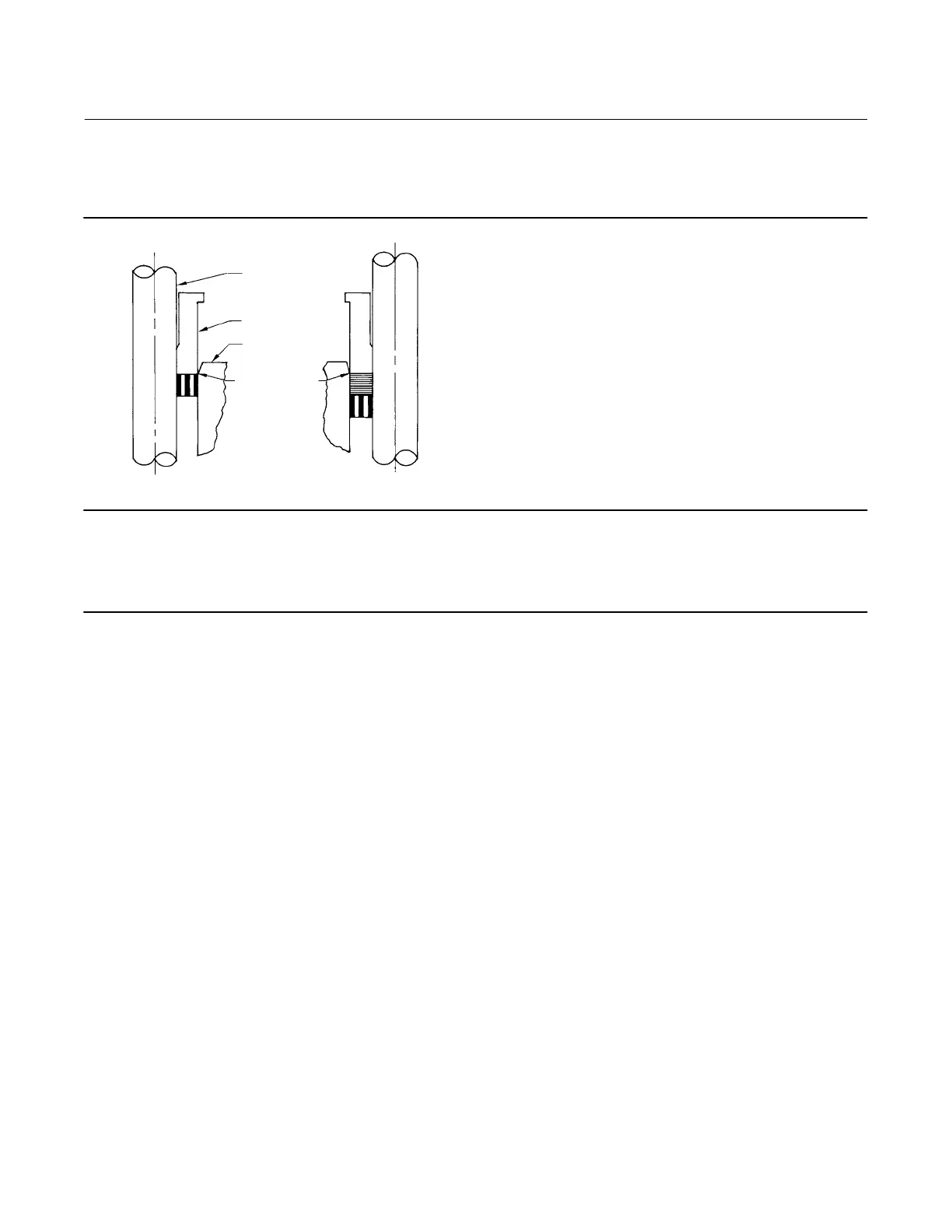

Figure 5. Installing Graphite Ribbon/Filament Packing Rings One at a Time

VALVE STEM

PACKING FOLLOWER

BONNET

TOP OF PACKING

RING EVEN WITH

BOTTOM OF

ENTRANCE

CHAMFER

INSTALLING

SECOND PACKING RING

A2207‐2

INSTALLING

FIRST PACKING RING

Note

If graphite ribbon/filament packing rings are used, special procedures must be observed to prevent entrapping air between the

rings. Add the rings one at a time without forcing them below the chamfer of the packing box entrance chamber. As each

successive ring is added, the stack should not be pushed down more than the thickness of the added ring (figure 5).

13. Install new packing and the metal packing box parts according to the appropriate arrangement in figure 4. If

desired, packing parts may be pre‐lubricated with a silicon base grease for easier installation. Slip a smooth‐edged

pipe over the valve stem, and gently tamp each soft packing part into the packing box, being sure that air is not

trapped between adjacent soft parts. For a valve with extension bonnet, also install the baffle and retaining rings

(keys 2 and 35).

14. Slide the packing follower, wiper, and packing flange into position. Lubricate the packing flange studs (key 4) and

the faces of the packing flange nuts (key 5). Replace the packing flange nuts.

For spring‐loaded PTFE V‐ring packing, tighten the packing flange nuts until the shoulder on the packing follower (key

13) contacts the bonnet.

For other packing types, tighten the packing flange nuts to the maximum recommended torque shown in table 7.

Then, loosen the packing flange nuts, and retighten them to the recommended minimum torque shown in table 7.

For ENVIRO‐SEAL or HIGH‐SEAL live‐loaded packing, refer to the note at the beginning of the Maintenance section.

15. Mount the actuator on the valve body assembly, and reconnect the actuator and valve plug stems according to

the procedures in the appropriate actuator instruction manual.

Trim Removal

For C‐seal construction, see the appropriate C‐seal sections in this instruction manual.

Trim removal and replacement requires the use of a seat ring retainer tool (key 25). If specifically ordered, a tool is

supplied with a valve; but, the tool can also be ordered separately by referencing the tool part number in the Parts List.

If desired, a tool can also be machined for a valve of specific size and valve class using the dimensions shown in figure

9. Machine the tool from a material listed in figure 9 or from a material with a yield strength of at least 827 MPa

(120,000 psi). Using a tool of lower strength material may result in damage to the seat ring retainer or valve body

threads.

Loading...

Loading...