Type 99

3

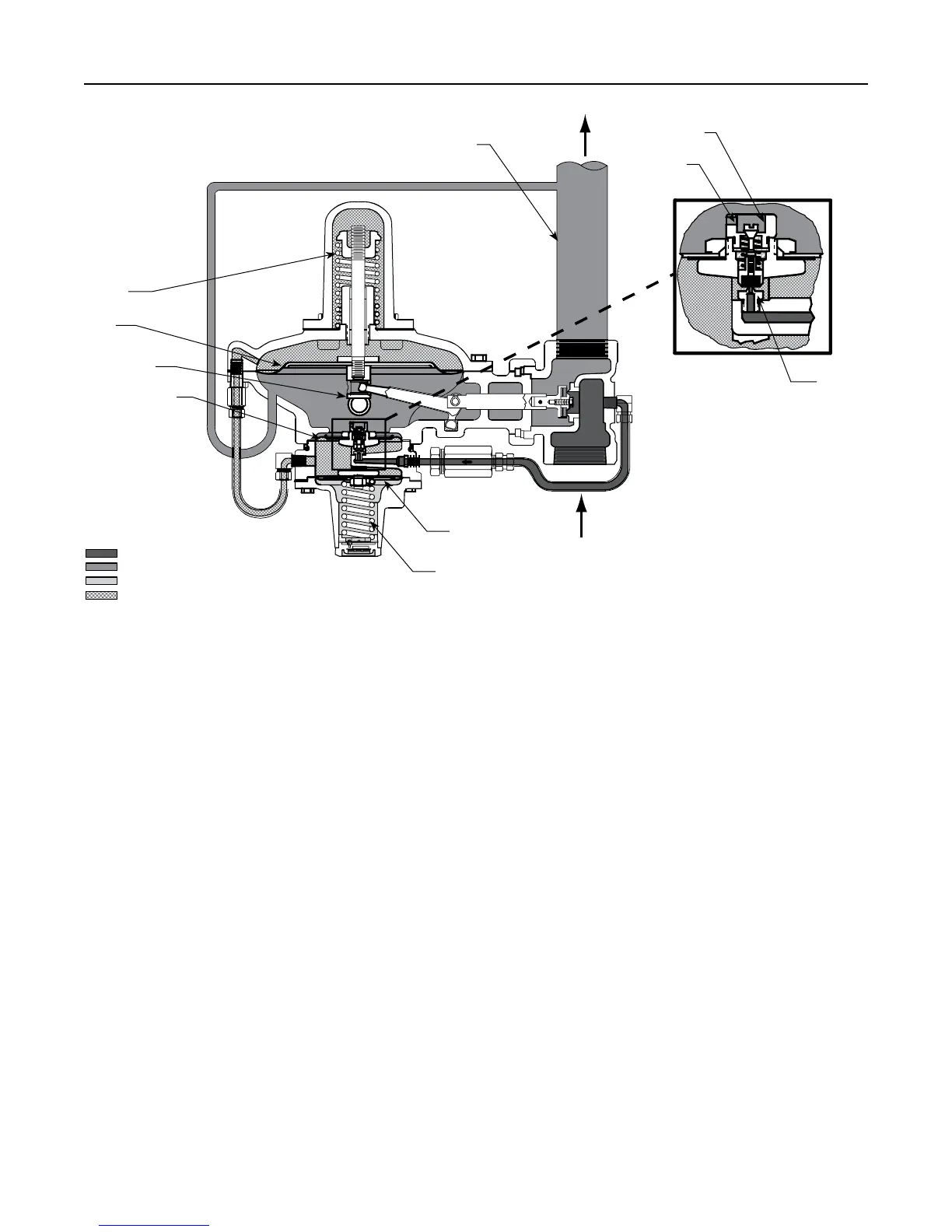

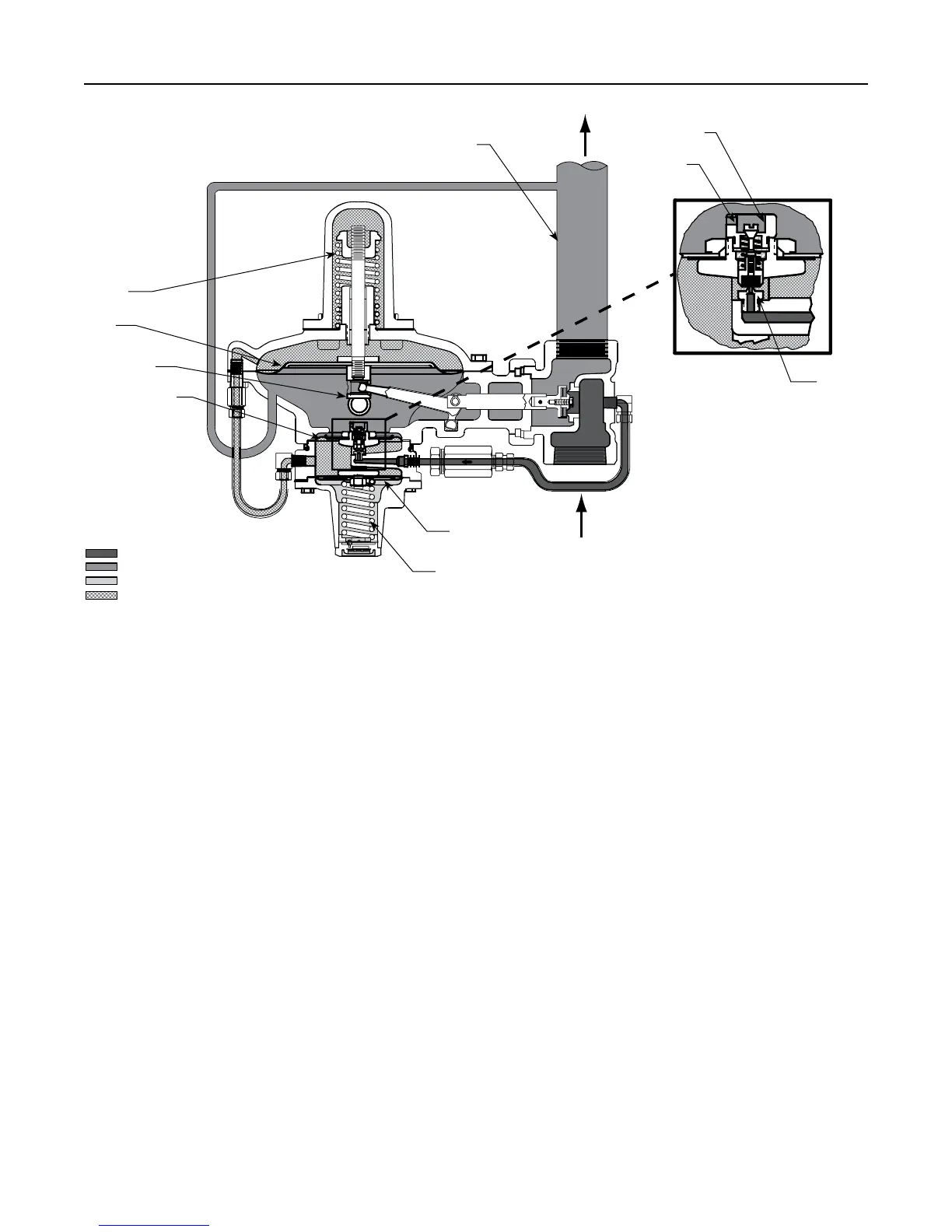

Figure 2. Schematic of Type 99 Regulator with Type 61L (Low Pressure) Pilot

A6814

OUTLET PIPE

PILOT

ORIFICE

BLEED

ORIFICE

BLEED VALVE

PILOT DIAPHRAGM

ASSEMBLY

PUSHER POST

ASSEMBLY

MAIN

DIAPHRAGM

MAIN VALVE

SPRING

PILOT CONTROL SPRING

PILOT DIAPHRAGM

INLET

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

Principle of Operation

The key to the operation of a Type 99 regulator is the

yoked double-diaphragm pilot. Fast response and

accuracy are made possible by the amplifying effect

of the pressure-balanced pilot and by the two-path

control system. The function of the pilot is to sense

change in the controlled pressure and amplify it into a

larger change in the loading pressure. Any changes

in outlet pressure act quickly on both the actuator

diaphragm and the loading pilot, thus providing the

precise pressure control that is a characteristic of a

two-path system.

A typical pilot has an approximate gain of 20, which

means the outlet pressure needs to droop only 1/20

as much as a direct-operated regulator in order to

obtain the same pressure differences across the main

diaphragm. Advantages of a pilot-operated regulator are

high accuracy and high capacity.

Upstream or inlet pressure is utilized as the operating

medium, which is reduced through pilot operation to

load the main diaphragm chamber. Tubing connects

the inlet pressure to the pilot through a lter assembly.

Downstream or outlet pressure registers underneath the

main diaphragm through the downstream control line.

In operation, assume the outlet pressure is less than

the setting of the pilot control spring. The top side

of the pilot diaphragm assembly will have a lower

pressure than the setting of the spring. Spring forces

the diaphragm head assembly upward, opening the

relay or inlet orice. Additional loading pressure is

supplied to the pilot body and to the top side of the

main diaphragm.

This creates a higher pressure on the top side of the

main diaphragm than on the bottom side, forcing the

diaphragm downward. This motion is transmitted

through a lever, which pulls the valve disk open,

allowing more gas to ow through the valve.

When the gas demand in the downstream system

has been satised, the outlet pressure increases.

The increased pressure is transmitted through the

downstream control line and acts on top of the pilot

diaphragm head assembly. This pressure exceeds

the pilot spring setting and forces the head assembly

down, closing the orice. The loading pressure acting

on the main diaphragm bleeds to the downstream

system through a small slot between the pilot bleed

valve and the bleed orice.

Loading...

Loading...