13

002 M5 3.2 4.3

003 M5 3.2 4.3

006 M5 3.2 4.3

012 M8 13.1 17.7

024 M10 26.2 35.5

036 M10 26.2 35.5

065 M12 45.2 61.3

090 M12 45.2 61.3

180 M16 108.5 147.1

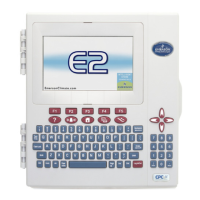

KEYSTONE FIGURE 79 PNEUMATIC ACTUATOR

OPERATING AND MAINTENANCE INSTRUCTIONS

MAINTENANCE

If basic pneumatic system procedures are

maintained, the Figure 79 actuators will require

minimum maintenance for many thousands of

cycles.

TROUBLESHOOTING

If loss or reduction of power (in output torque)

occurs, take the following steps:-

1. Check air supply.

2. Check for o’ring leakage at the following

‘A’ Top and Bottom Bearing Seals

Apply pressure to PORT A and check with

soap/water solution for leaks at the top and

bottom bearing seals.

‘B’ Endcap Seals

Apply air pressure to PORT B and check

endcap joints for leakage.

‘C’ Piston Seals

Apply air pressure to PORT B and check

PORT A for leakage.

For access to ‘O’-ring seals in order to

replace, refer to Disassembly procedures

for appropriate models i.e. single or double

acting.

Note: Reduced stroke i.e. valve to which

actuator is fitted not travelling the required

stroke or “backlash” may be caused by an

incorrect fit between output bore and valve

stem.

GENERAL INFORMATION

As standard, clockwise to close rotation, air to

PORT A will rotate the actuator to the OPEN

position. Air to PORT B will rotate the actuator

to the close position.

Warning - for safety reasons DO NOT ‘Air

Assist’ single acting pneumatic actuators.

RECOMMENDED TIGHTENING TORQUES FOR END CAPS

Torque

Models Bolt Diameter (Nm) (lbs-ft)

STANDARD SPRING COLOR CODES

Spring Rating

Models 003S to 180S

End 1 End 2

40psi - 2.8bar Light Blue Light Blue

50psi - 3.5bar Light Blue White

60psi - 4.2bar White White

70psi - 4.8bar Light Blue/Dark Blue* White

80psi - 5.5bar Light Blue/Dark Blue* Light Blue/Dark Blue*

90psi - 6.2bar Light Blue/White* Light Blue/Dark Blue*

100psi - 6.9bar Light Blue/White* Light Blue/White*

* Nested (double) springs

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Keystone is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson

and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by

our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without

notice.

Emerson.com/FinalControl

Loading...

Loading...