5

KTM POWDER DISCHARGE SYSTEM (PDS) METALTITE

®

BALL VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

CAUTION

1. Ensure that there are no solid objects such as

pieces of wood, plastic or packing materials

within the valve or on the valve seat. It is

recommended to flush pipes before installing

the valve. If this is not possible, the installed

valve must be in its open position before

flushing takes place.

2. Unless otherwise recommended by KTM, the

valves should be installed with the ball in open

position to ensure that the seat rings are not

damaged during installation.

3. Use appropriate gaskets which comply with

standards or specifications.

4. Tighten the flange bolts with a closed wrench,

using a “crisscross” pattern that alternately

tightens the bolts located 180 degrees apart

(see Figure 1). Unequal partial tightening

places stress on lined pipes which may

damage the flange or produce excessive

operation torque.

5. Failure to fabricate pipes without excessive

stress will result in leakage, poor operation

or failure of the valves.

6. When conducting a pressure test of the pipe

system, the valves should be in a partially open

position. Testing at closed position will impose

too much load and will cause leakage from

seats. Check for any leakage from the joint

flange and gland portion during the pressure

test. After conducting the pressure test, return

to fully open/closed position at once.

7. If the piping system is pressurized with water

for testing, and if the piping system has been

shut down for a long time after testing, the

following measures should be taken:

• Use corrosion inhibitor with water to

pressurize the piping system.

• After testing, the piping system should be

depressurized and the test water completely

drained.

• Ensure that the corrosion inhibitor does not

leave a residue within the system as the

particulates may damage the valve sealing

surfaces.

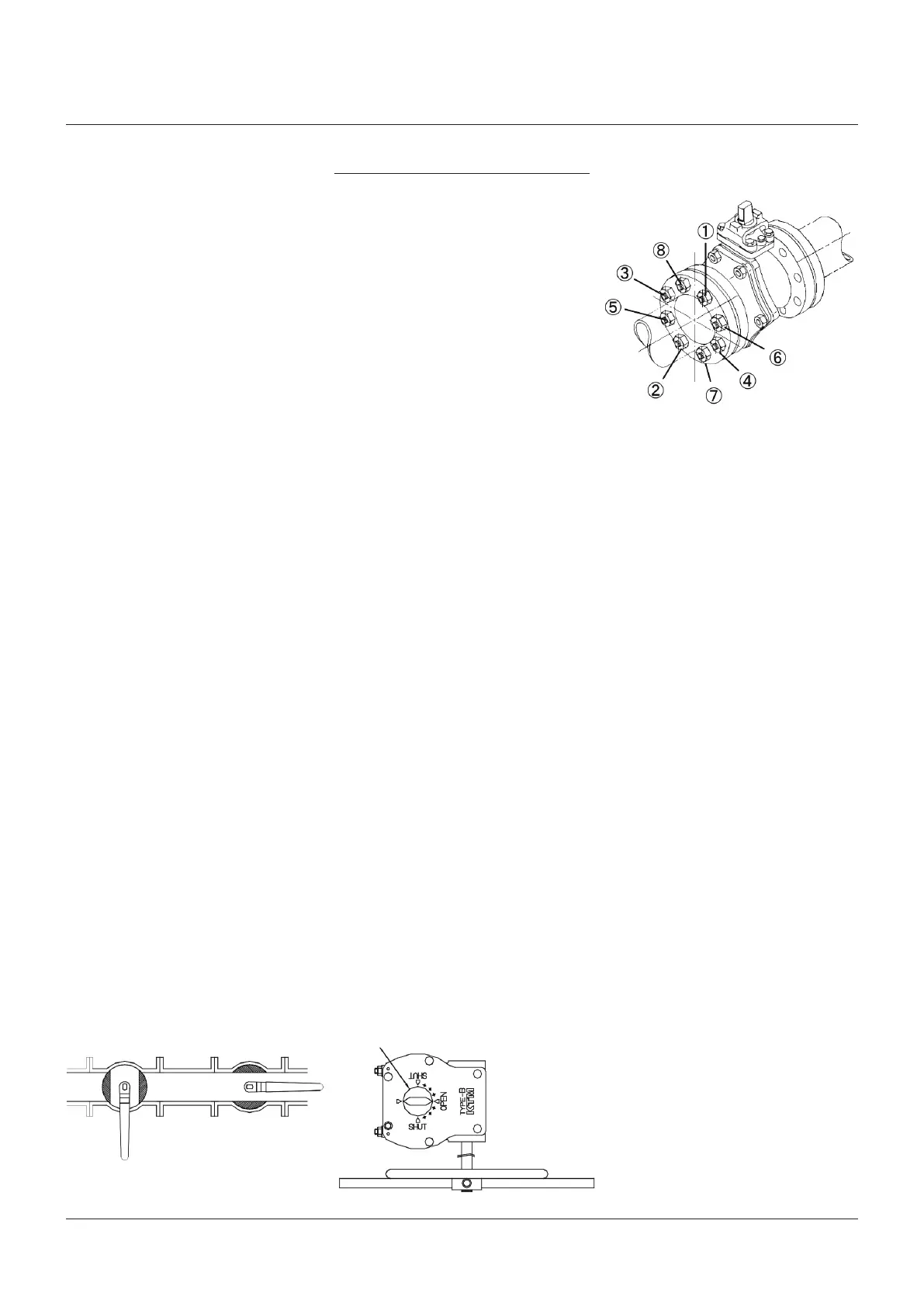

FIGURE 1

Tightening of bolts

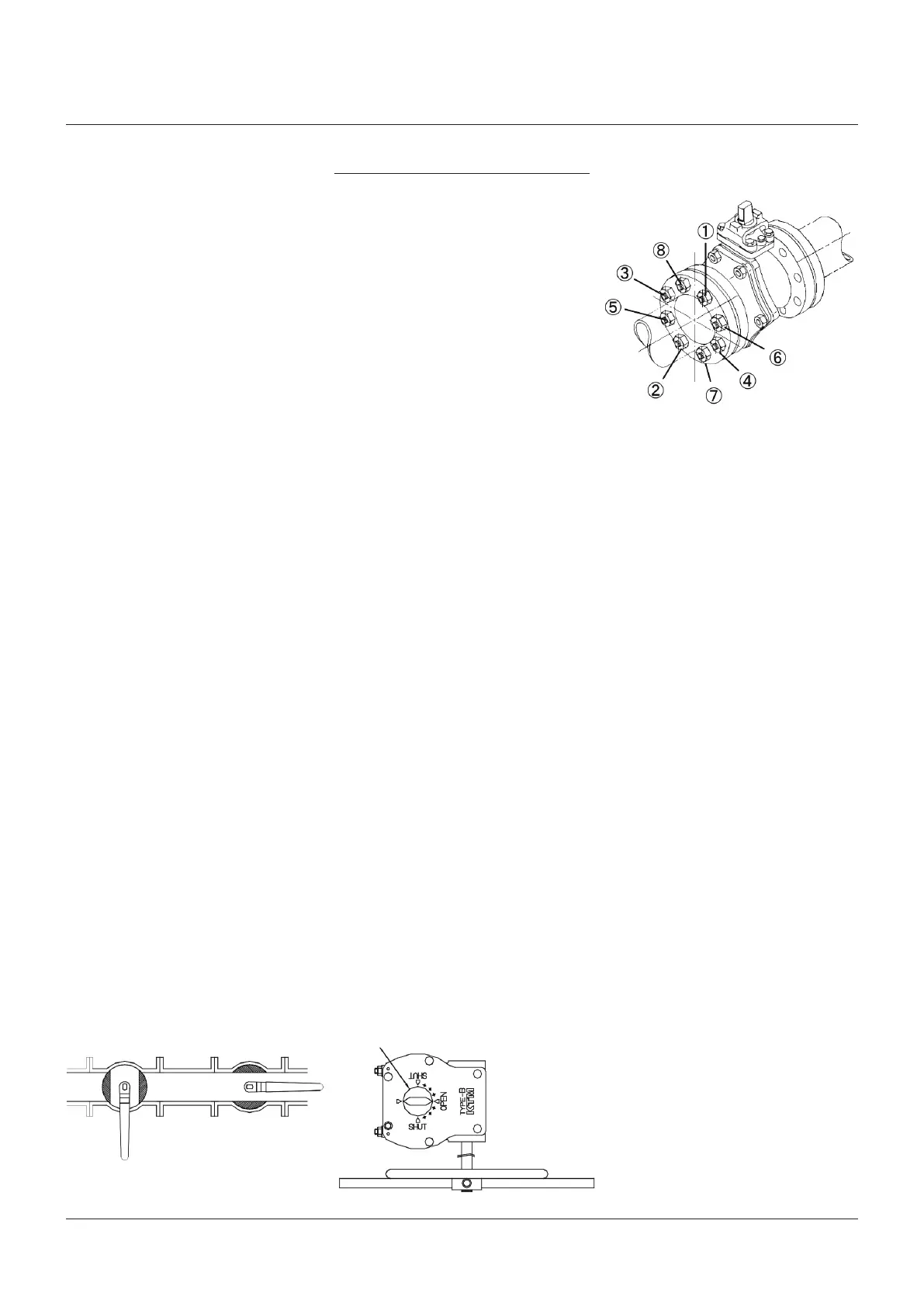

FIGURE 2

Lever handling valve

FIGURE 3

Gear operated valve

7 OPERATION

7.1 Operation instruction

Valve adjustment is performed through lever

handle/gear operation. Turning the stem

clockwise shuts the valve. Check the operation

of the valve by stroking it to “fully open” and

“fully closed”. Either the hand lever or the

direction of the parallel flats on the top of the

stem indicate the open or close position of the

KTM ball valves (Figure 2). For gear operated

valves, the position is indicated by the arrow-

indicator (Figure 3).

WARNING

1. Operate the valve taking up a stable posture,

after checking that the specified handle

is fastened by bolts/nuts or snap ring/set

screw. Also, when operating the valve with

a spare handle, please make sure that the

handle is reliably inserted into the stem’s end.

Insufficient insertion and forced operation of

the handle may result in damage or injury if

the handle slips out.

2. Excessive handle operation may break the

lever, injure the operator, and/ or deform the

stopper or the stem, which may also result in

seat leakage.

3. Be careful in handling the valve where high

temperature fluid flows in the pipeline. The

heated valve may cause burn injury of bare

hands.

7.2 Gear operated valve adjustment

If the gear-operated mechanism indicator

does not correctly indicate whether the valve

is completely open or shut, adjust the opening

with the adjustment screw. For details, refer to

document No. C325-330, “Instruction Manual of

A, B, C and D typed Gear Operational Valves”.

Valve closed Valve opened

Indicator

Loading...

Loading...