8

KTM POWDER DISCHARGE SYSTEM (PDS) METALTITE

®

BALL VALVES

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

ASME CLASS 150 MODEL E0105MK, E0125MK / ASME CLASS 300 MODEL E0106MK, E0126MK

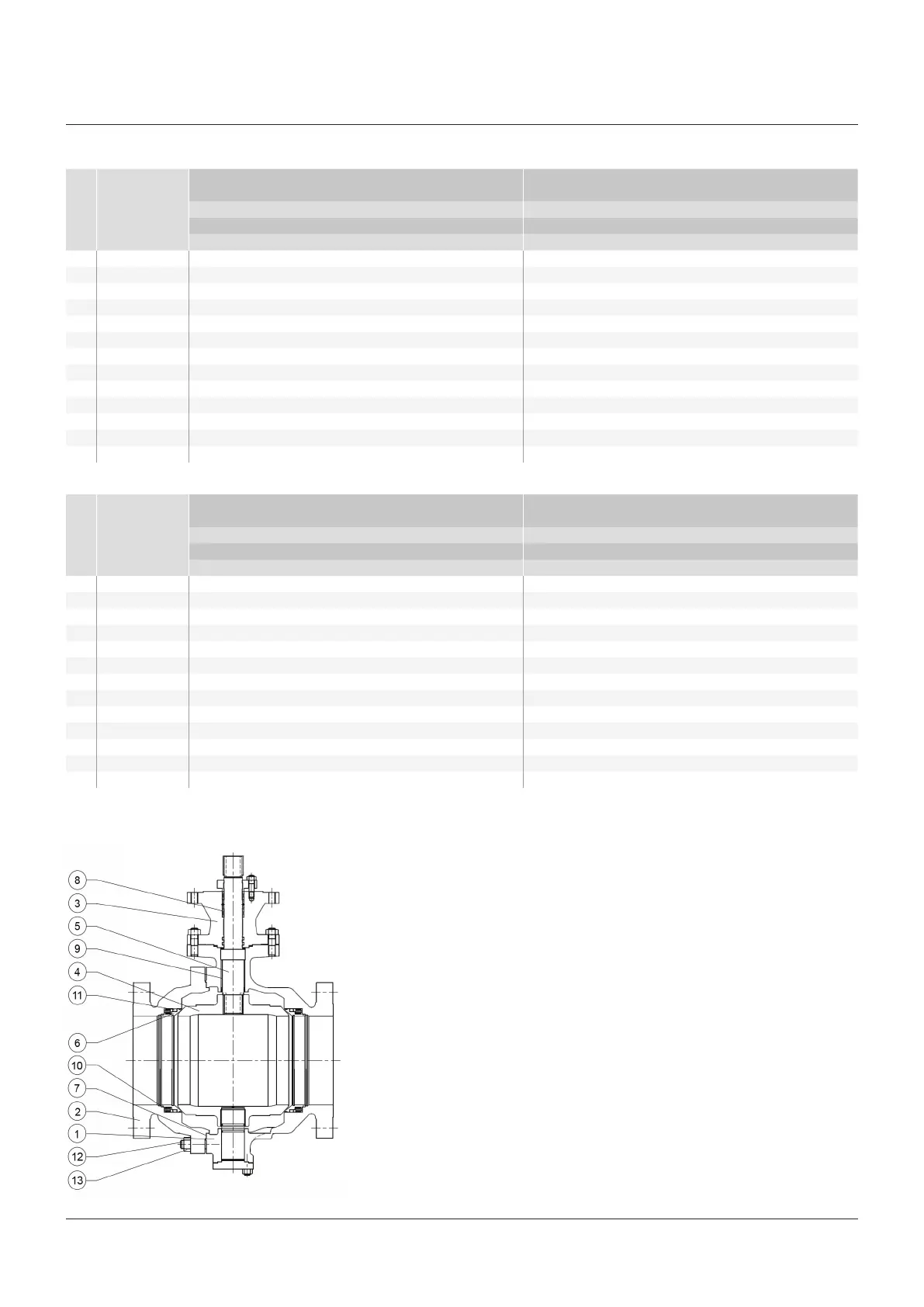

No. Parts name

Body material: carbon steel Body material: stainless steel

Material code Material code

62BY 62BG 62WY 62WG 32BY 32BG 32WY 32WG

Temperature range Temperature range

-29° to 150°

[1]

-29° to 150°

1 Body WCB (SCPH2) CF8M (SCS14A)

2 Body cap WCB (SCPH2) CF8M (SCS14A)

3 Extended bonnet WCB (SCPH2) CF8M (SCS14A)

4 Ball CF8M (SCS14A) + SFNi CF8M (SCS14A) + WC CF8M (SCS14A) + SFNi CF8M (SCS14A) + WC

5 Stem SCM435H + ENP SCM435H + ENP

6 Seat 316SS + Stellited 316SS + WC 316SS + Stellited 316SS + WC

7 Gasket RPTFE Graphite RPTFE Graphite RPTFE Graphite RPTFE Graphite

8 Gland packing RPTFE Graphite RPTFE Graphite RPTFE Graphite RPTFE Graphite

9 Stem bearing PEEK PEEK

10 Spring 316SS 316SS

11 Seal ring FKM

[2]

FKM

[2]

12 Stud bolt A193 G B7 A193 G B7 + Zn

13 Nut A194 G 2H A194 G 2H + Zn

ASME CLASS 600 MODEL E0108MK

No. Parts name

Body material: carbon steel Body material: stainless steel

Material code Material code

62BY 62BG 62WY 62WG 32BY 32BG 32WY 32WG

Temperature range Temperature range

-29° to 150°

[1]

-29° to 150°

1 Body WCB (SCPH2) CF8M (SCS14A)

2 Body cap WCB (SCPH2) CF8M (SCS14A)

3 Extended bonnet WCB (SCPH2) CF8M (SCS14A)

4 Ball CF8M (SCS14A) + SFNi CF8M (SCS14A) + WC CF8M (SCS14A) + SFNi CF8M (SCS14A) + WC

5 Stem SCM435H + ENP SCM435H + ENP

6 Seat 316SS + Stellited 316SS + WC 316SS + Stellited 316SS + WC

7 Gasket Spiral wound gasket Spiral wound gasket

8 Gland packing RPTFE Graphite RPTFE Graphite RPTFE Graphite RPTFE Graphite

9 Stem bearing PEEK PEEK

10 Spring 316SS 316SS

11 Seal ring FKM

[2]

FKM

[2]

12 Stud bolt A193 G B7 A193 G B7 + Zn

13 Nut A194 G 2H A194 G 2H + Zn

NOTES

1. Lower limit temperature for SCPH2 is -5°,

WCB is -29°.

2. Will use FVMQ in case of -29°.

Materials in parentheses indicate equivalent JIS

material or generic name.

SFNi Nickel Alloy overlay

WC Tungsten Carbide coating

ENP Electroless Nickel plating

Zn Zn plating

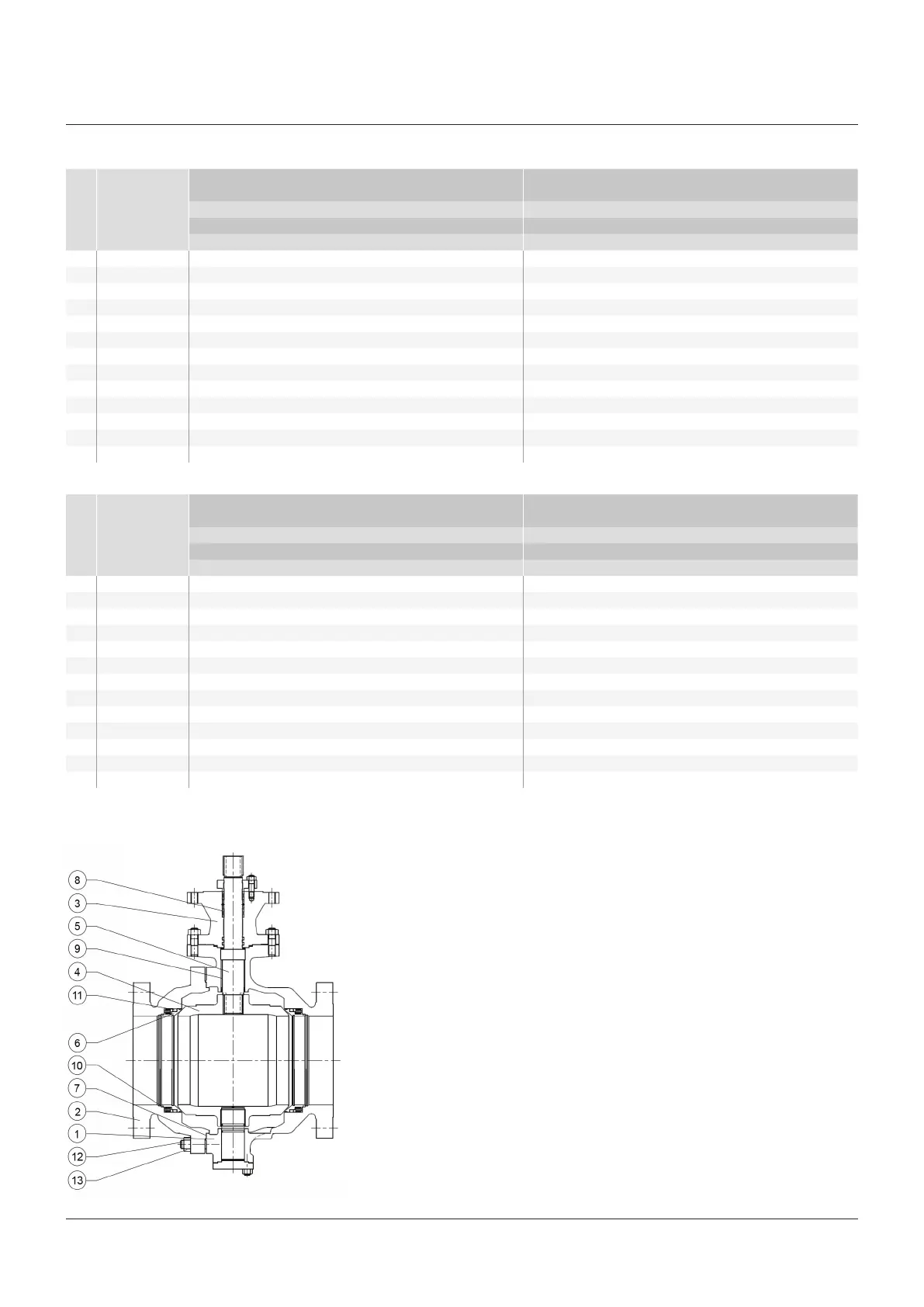

FIGURE 6

Construction drawing

Loading...

Loading...