8 Unidrive M200-201 Quick Start Guide

Issue Number: 6

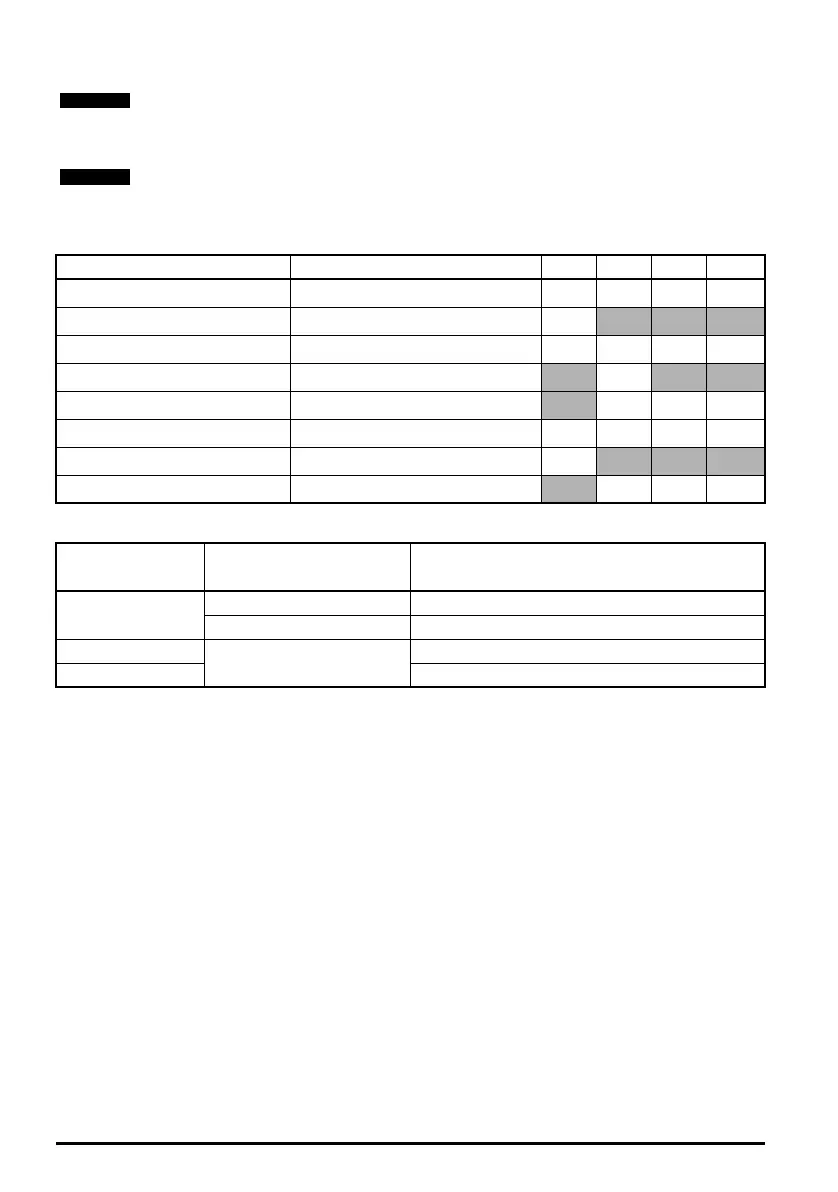

Table 3-1 Tools required

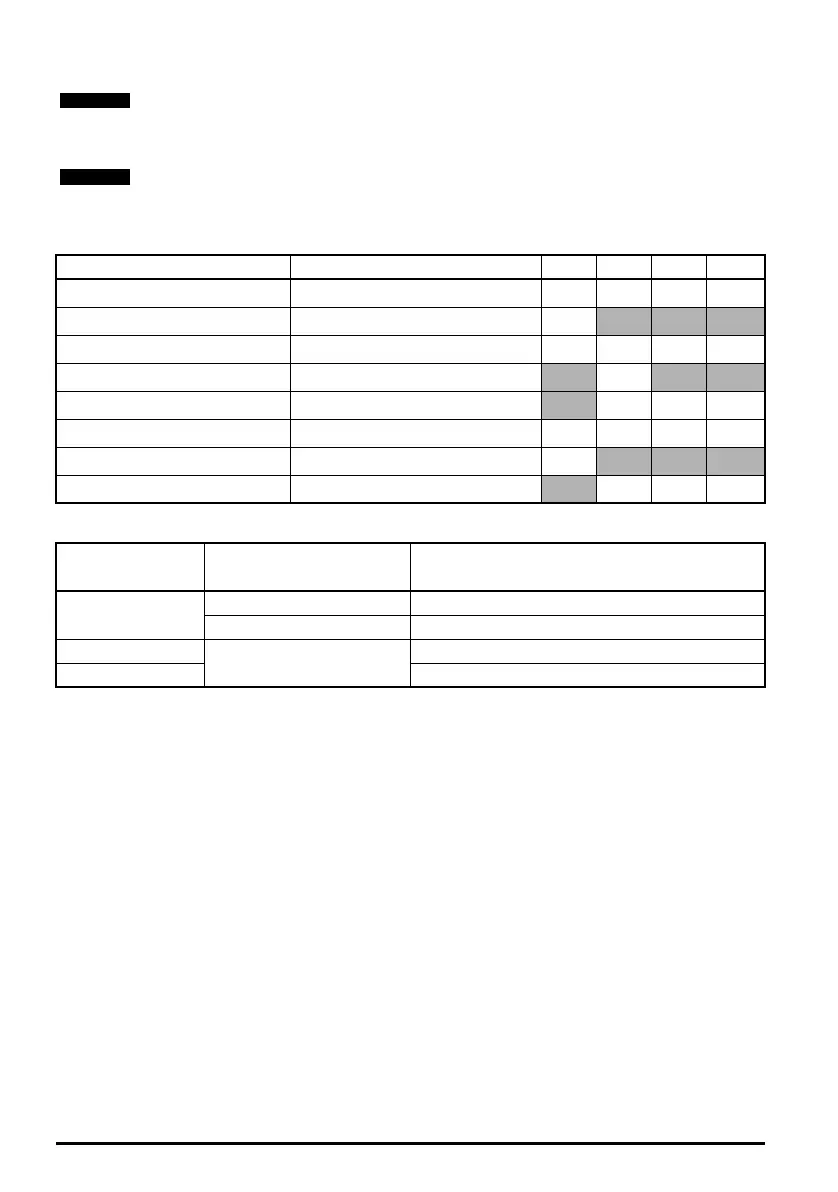

Table 3-2 Recommended torque settings

Derating for reduced clearances is to be applied in addition to the derating for increased

switching frequency if operating above 3 kHz. Refer to the Drive User Guide for the current

derating due to an increase in switching frequency.

If Din rail mounting is used in an installation, then mounting screws should be used to

secure the drive to the back plate.

Tool Location Size 1 Size 2 Size 3 Size 4

Small terminal screwdriver Control, relay terminals

9999

3 mm Flat-bladed screwdriver Power terminals

9

5 mm Flat-bladed screwdriver Terminal cover

9999

4 mm Flat-bladed screwdriver AC power terminals

9

Philips screwdriver Power terminals

999

Torx 10 driver EMC & MOV screws

9999

Torx 15 driver Fan screw

9

Torx 20 driver Fan screw

999

Model size

Terminal block

description

Torque settings

All

Control terminals 0.2 N m (0.15 Ib ft)

Relay terminals 0.5 N m (0.37 Ib ft)

1

Power terminals

0.5 N m (0.37 Ib ft)

2, 3, 4 1.4 N m (1.03 Ib ft)

Unidrive M200 201 Quick Start Guide English Iss6.book Page 8 Thursday, September 10, 2015 1:48 PM

Loading...

Loading...