9. Install supplied O-ring in the O-ring groove of the new control.

Remove "knockout plugs" from the junction box or electrical

enclosure of the new control.

Onscrollcompressors,installinjectiontubeperdiagram–notethatit

installs at a slight angle (Figure 2). Thread tube in handtight and tighten

½ turn with a wrench or pliers.

10. With the solenoid off, mount and level the new control to existing

adapter using 1/4 - 20 UNC-2A x 3/4" long bolts:

A.IfreplacinganOMBoranOMC,turntheringedadapterange

approximately 1/4 turn counterclockwise to provide the correct three

(3) hole alignment since the holes are not equidistant.

(Important: If the current adapter has an O-ring groove, replace with

the correct adapter for the application - see catalog.)

B. If replacing an OMC CO

2

,allve(5)holesbetweentheadapterand

control should be alligned correctly.

Be sure that the O-ring has not fallen out of the groove and tighten

bolts evenly to 40 in.-lbs.

11. Reconnect the oil inlet line.

12. With pressure valved off, remove gauge manifold, cap ports, open

service valves and check for leaks.

13. If reconnecting an OMB refer to step A, if connecting an OMC refer to

step B

A. (OMB) Reconnect electrical power following color code and install

solenoid coil and power plugs. Note: Do not energize solenoid coil

before replacing on enclosing tube.

B. (OMC) Remove cover and refer to wiring schematic below to

reconnect power following color codes. Replace cover and assemble

screws to hand tight using #1 Phillips screwdriver. Note: Do not use

electronic screwdriver.

14. Check that the green LED is on. Yellow LED should come on after

about 10 seconds.

15.Checkthatthesolenoidisenergizedandthatthecontrolislling.

(Note:Ifcrankcasedoesnotllin2minutes,theredLEDshouldcome

on.)(Solenoidremainsontocontinuelling.)Ifthealarmtripsbefore

thecrankcaseislledto½sightglass,removepowertooilcontrolfor

several seconds and reinstall to reset alarm. If OMB, disconnect power

by removing power plug. If OMC, refer to wiring schematic below.

Compressorshouldthenllto1/2sightglassandyellow"ll"LED

should go out.

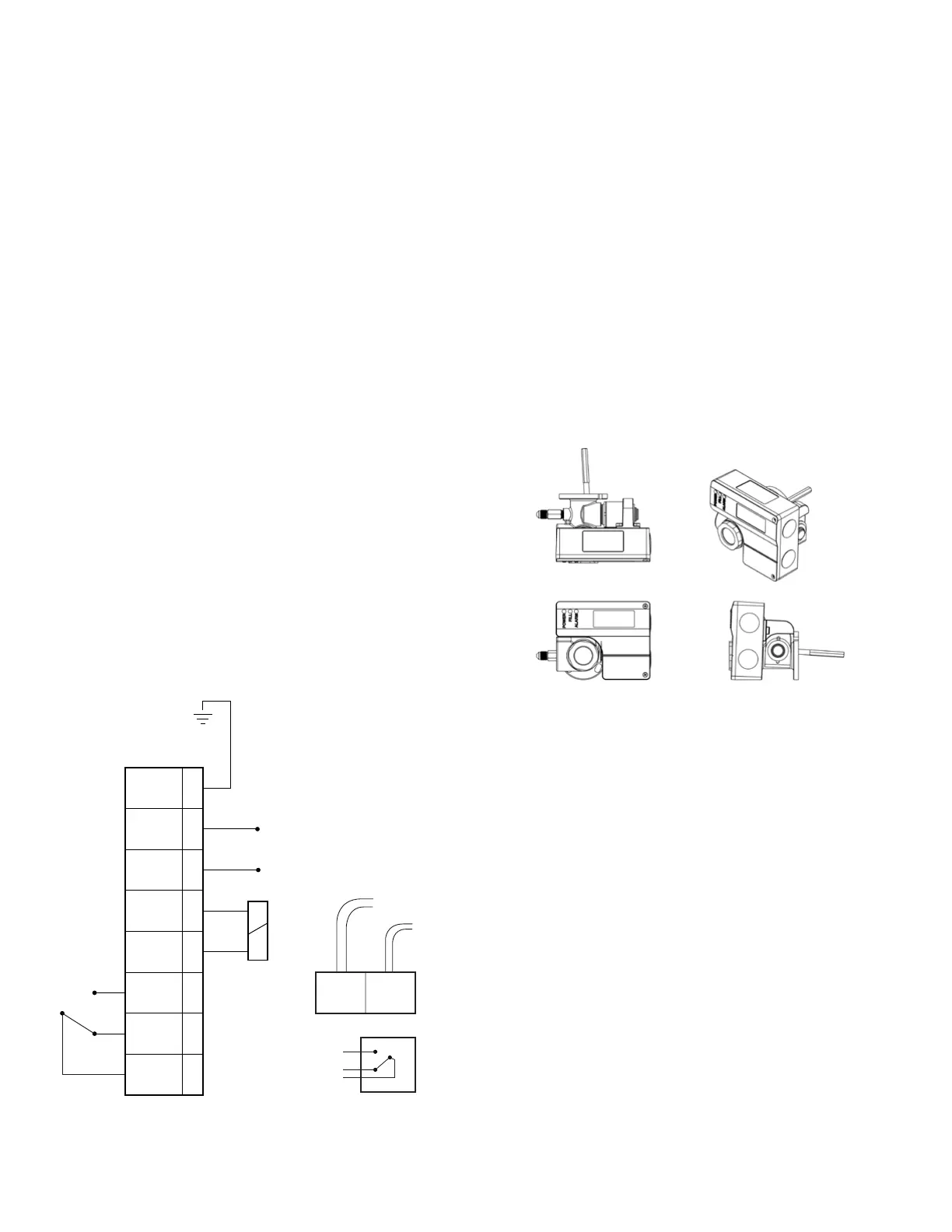

OMC

FIGURE 2

Note: Use of crimp type wiring connectors is highly recommended. If

wire nuts must be used, taping joint after assembly with electrical tape is

required.

Technical Support: 1 888 725 9797

PA-00388 (4/18) Emerson is a trademark of Emerson Electric Co. ©2018 All rights reserved. Emerson.com/White-Rodgers

16. Restart the compressor using the reverse procedure to shutting

it down.

17. Recheck for leaks and repair if necessary.

Important: Injection tube is not used on reciprocating compressors

where the control is mounted directly to the crankcase.

LED Codes When Lit:

Green –PowerissuppliedtoOMB/C.

Yellow –Floatsensordeterminedthattheoillevelhasbeenbelow

½ sight glass for over 10 seconds. Fill solenoid has been activated.

Red (continually lit)–Oillevelhasremainedbelow½sightglassfor

overtwominutesafterllsolenoidhasbeenactivated.Alarmhasbeen

activated and compressor is prevented from operating until oil level

reaches ½ sight glass when alarm automatically resets.

Red (ashing)–Therehavebeenveautoresetalarmsregisteredwithin

a 30 minute period. Alarm circuit is now locked on and compressor locked

off. Fill solenoid is de-energized. Alarm remains locked in until power lead

is manually unplugged and again plugged back into device.

Note: OMB/C units used on scroll compressors require the use of an

injection tube this tube is shipped wired to the unit but not installed.

It is to be screwed into the rear of the unit, and tightened hand tight

plus one half turn. When properly installed, the tube will be at a slight

angle relative to the OMB/C . See gure 2 below.

OMBOMC

FIGURE 1

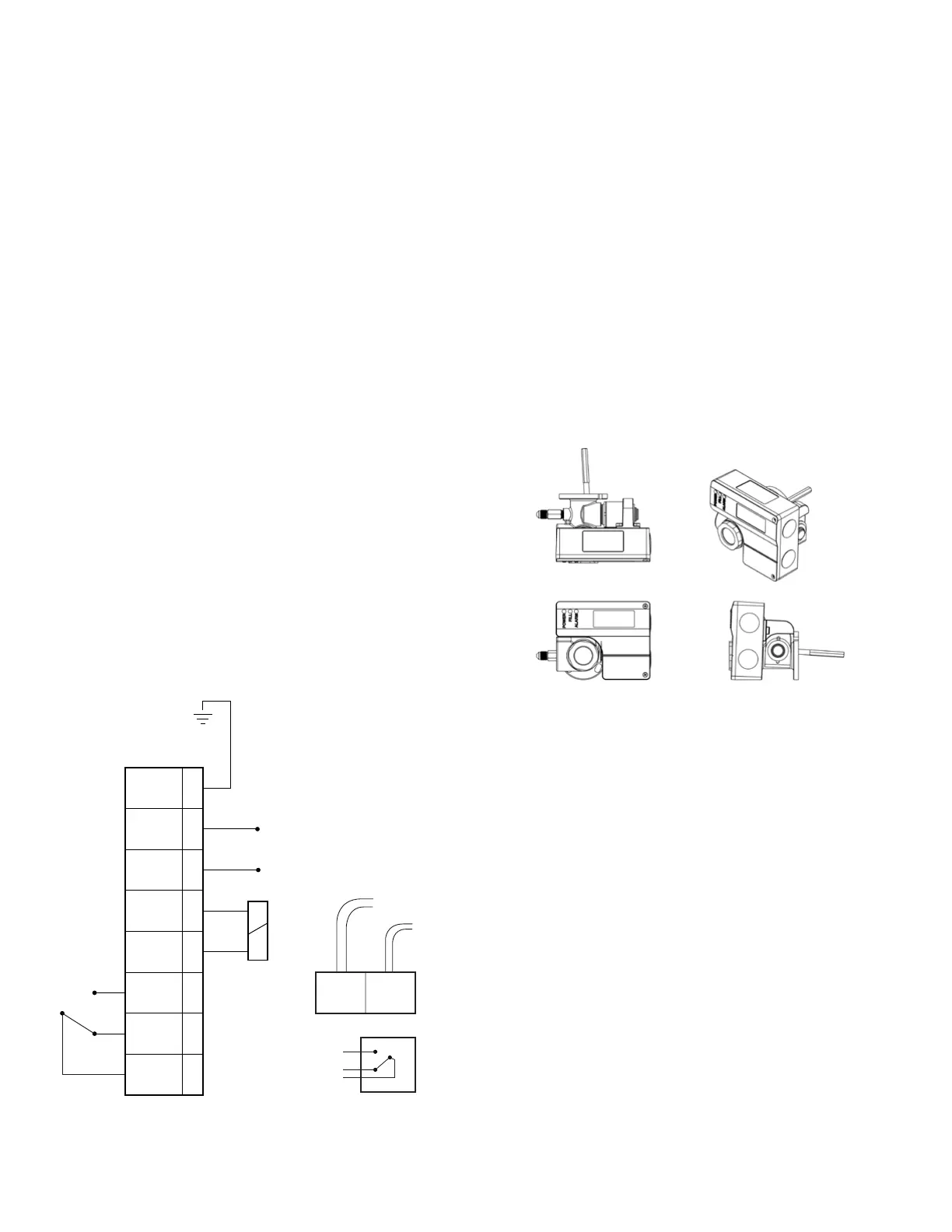

Electrical Wiring Diagram

8

7

6

5

4

3

2

1

Relay

Common

Closed in Alarm

Open in Alarm

Factory

Wired

Norm

Closed

Norm

Open

PE

GND

Solenoid

Solenoid

L2 L2

L1 L1

Supply

Voltage

Solenoid

Alarm Contacts

Factory Wired

to Coil

To Transformer

24 VAC

Orange - Common

Brown - Open in Alarm

Red - Closed in Alarm

Loading...

Loading...