PCD (Pitch Circle Diameter) / Bolt-Hole

The EM250 PCD calculator operates on the work-to-zero principle for the machining of a regular series of holes

around a datum. This datum is entered as the centre of the circle to be machined. Complex hole patterns can be

achieved easily without the need of detailed trigonometric calculations as these are all performed by the DRO.

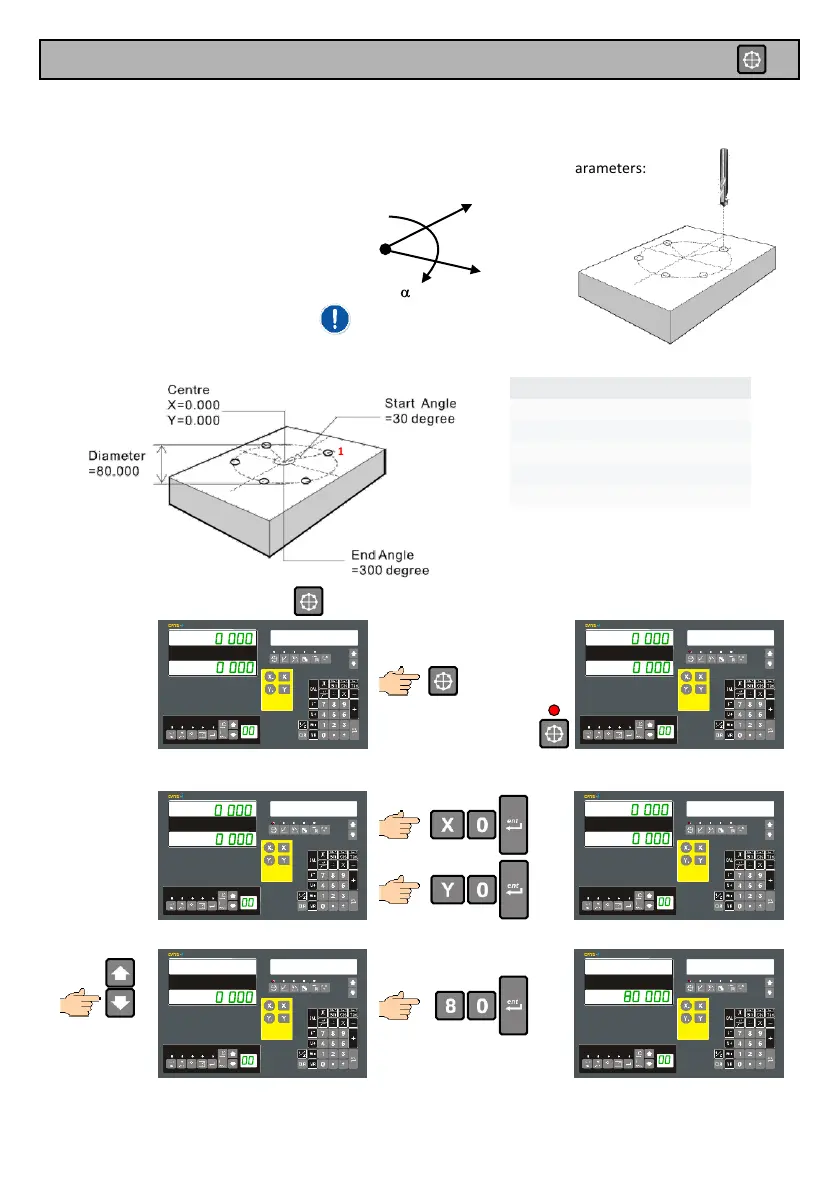

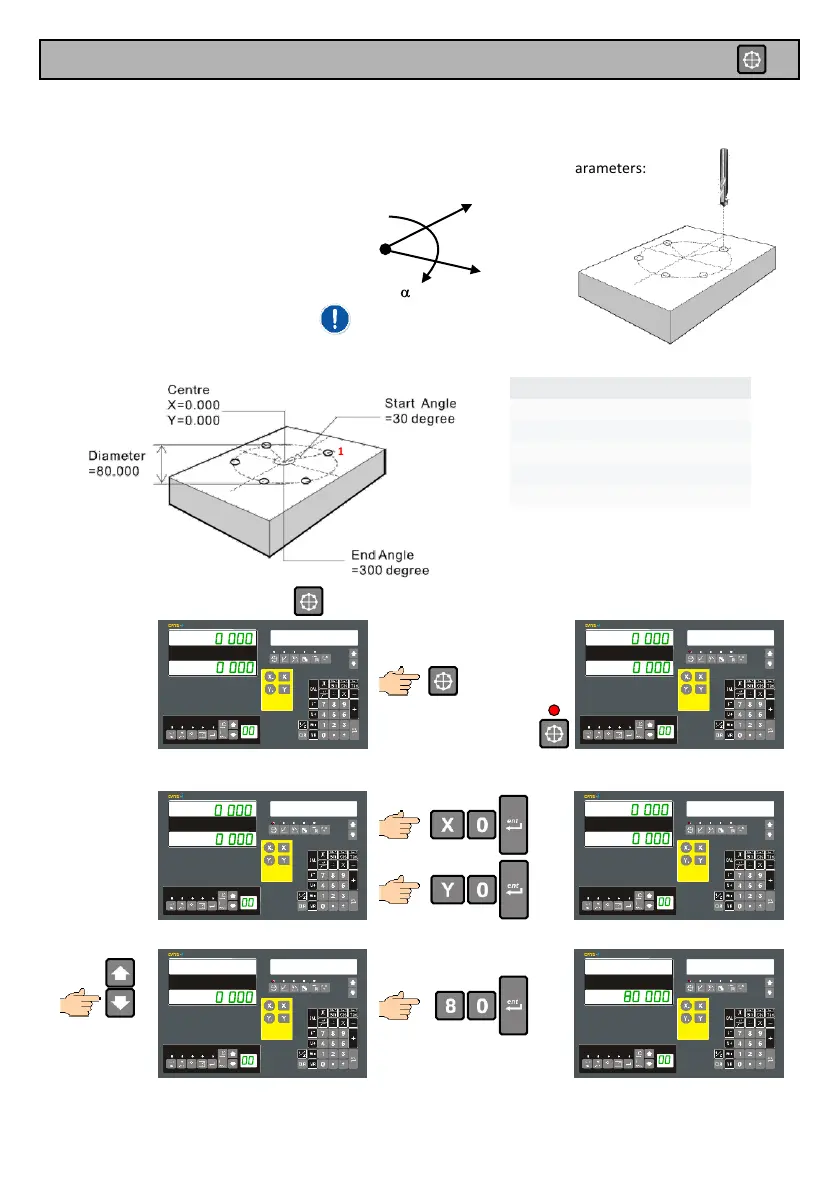

To achieve these calculations the DRO needs to be configured with the following parameters:

● Centre of the circle

● Diameter of the circle

● Number of holes required

● Start angle of the first hole

● End angle of the last hole

X+

Y+

+

Angles are positive clockwise

1

To best demonstrate these methods let us consider the part below as by way of example.

Parameter Value

Centre co-ordinates 0.000, 0.000

Diameter 80mm

Number of Holes 5

Start Angle 30o

End Angle 300o

If a full circle is needed:

●

Start Angle = 0o

●

End Angle = 360o

ABS

CENTRE

Enter the PCD function by pressing the key. The key LED will be illuminated showing the function is active.

CENTRE

Enter the co-ordinates of the centre of the PCD circle.

CENTRE

Use the Message

Navigation keys

DIA

Move to Diameter entry and enter value.

DIA

- 21 -

Loading...

Loading...