- -

11

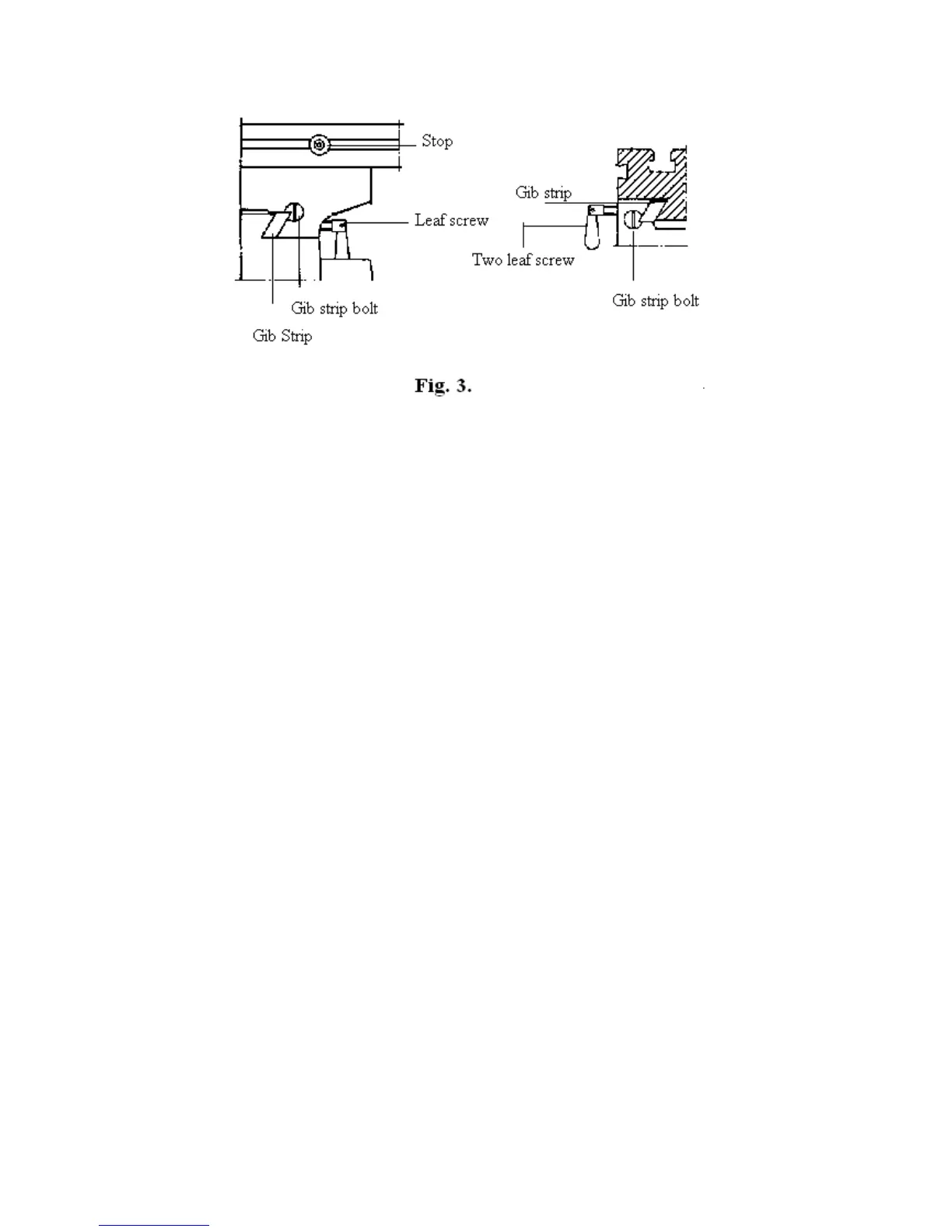

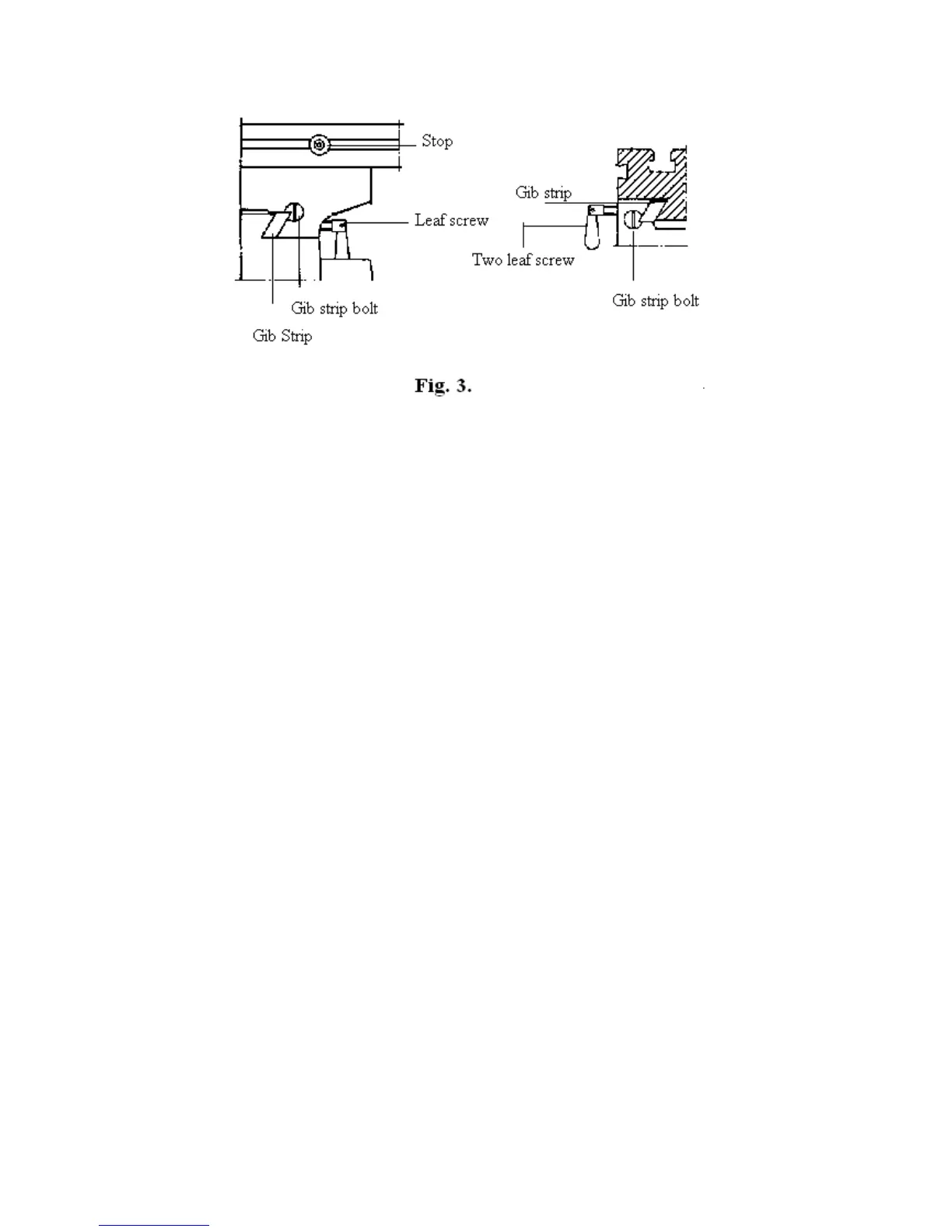

8. CLAMPING, TABLE BASE, AND MACHINE BASE (see Fig. 3)

(1) When milling longitudinal feed, it is advisable to lock the cross feed table travel to insure the

accuracy of your work. To do this, tighten the small leaf screw located on the right side of the

table base.

(2) To tighten the longitudinal feed travel of the table for cross feed milling, tighten the two small

leaf screw on the front of the table base

(3) Adjustable travel stops are provided on the front of the table for control of cross travel and the

desired milling length.

9. SPEED CHANGING AND ADJUST BELT (Step See Fig. 4)

(1) Turn power off.

(2) Open belt cover by releasing side latches step see(a)(b)(c).

(3) Loosen motor mount leaf screw.

(4) Push motor in order to loosen belts(head side of motor mount is set fixed, two motor's ear side

with motor screw to tighten or loosen of belts.)

(5) Loosen two screws for base of speed change inter pulley that also adjust the location of base for

speed change inter pulley.

(6) Select the suitable R.P.M. from speed charts of table 1. Then place the belts on the desired

pulley steps.

(7) Tighten two screws of base for speed change pulley and the bolt of motor mount lock.

(8) Cover the belt cover before turnning power on.

Loading...

Loading...