- -

14

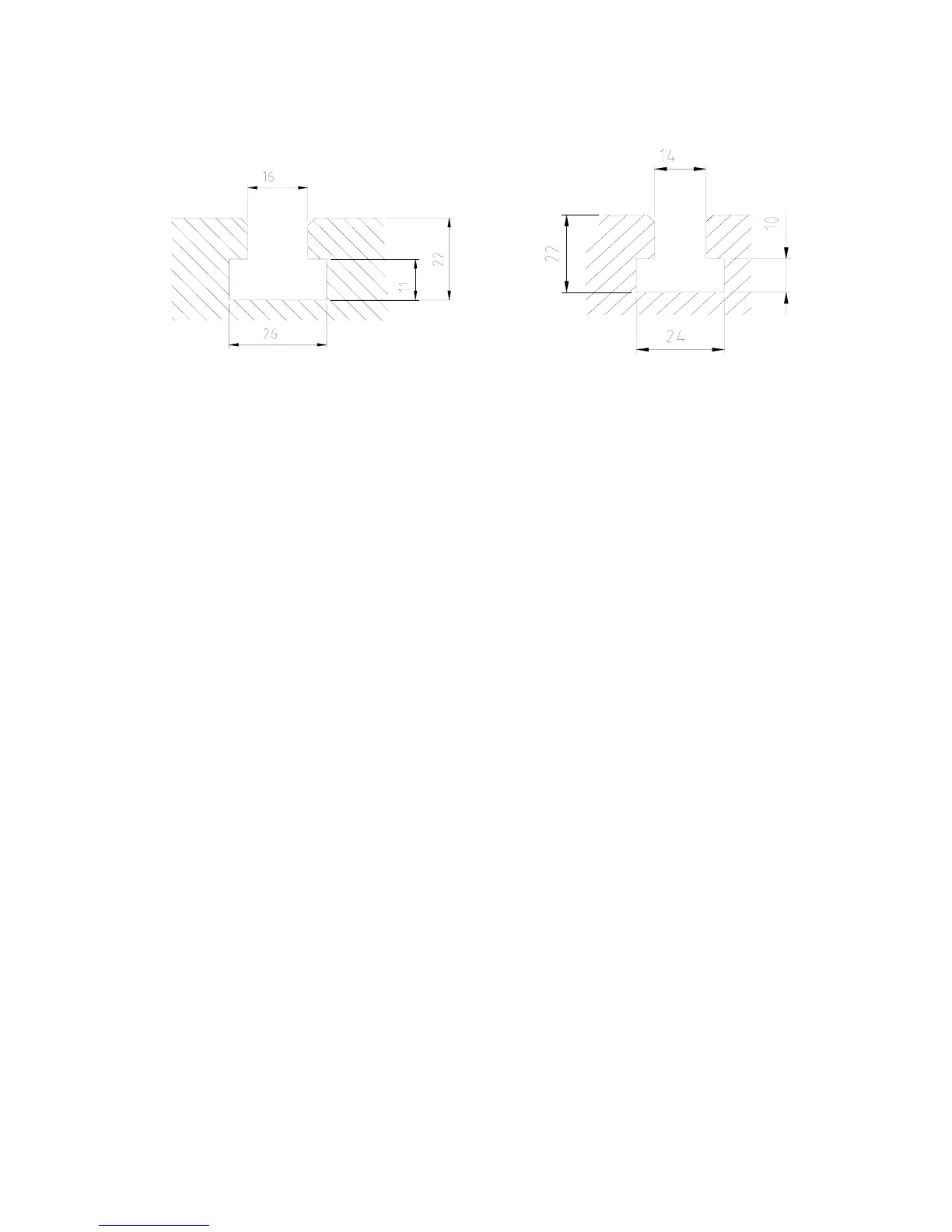

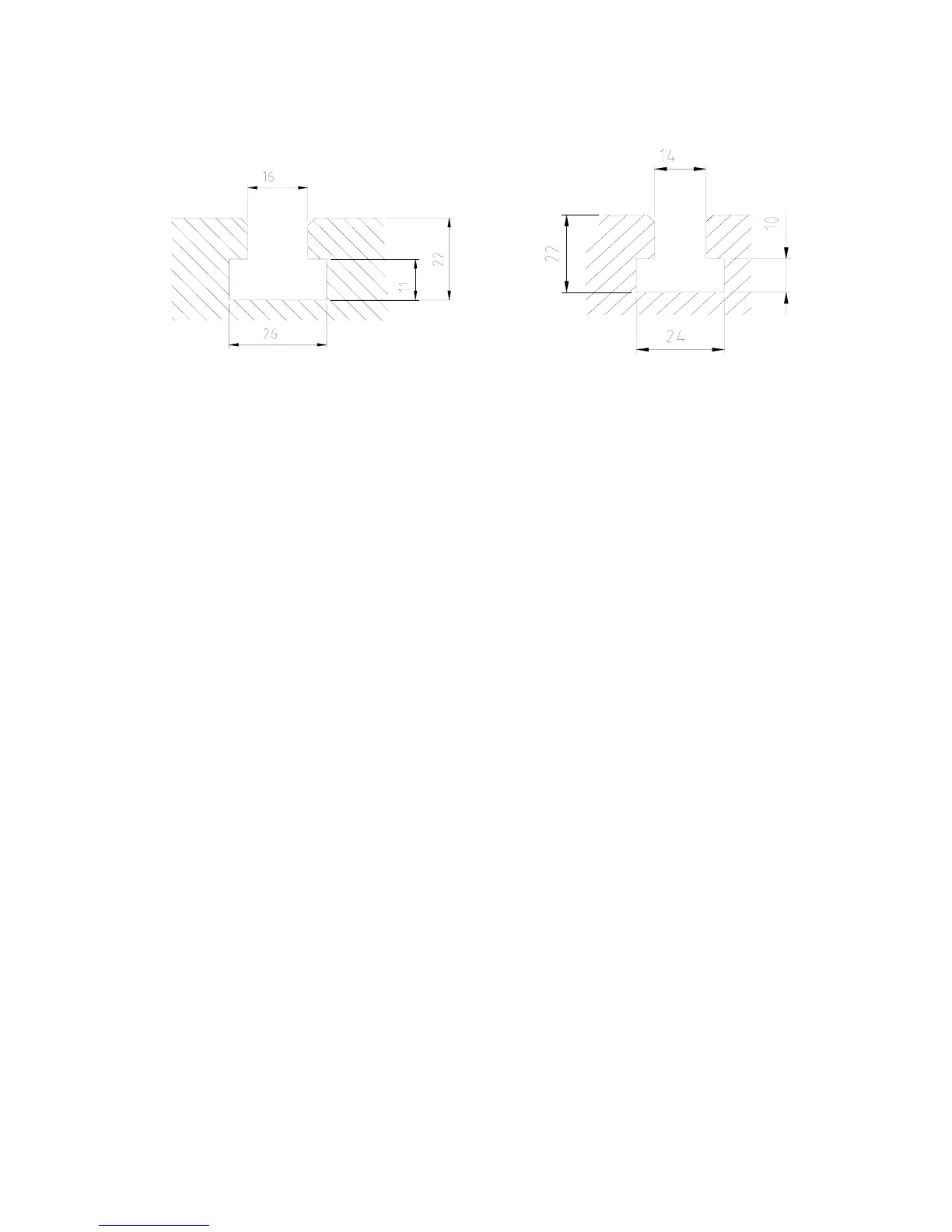

15. SPECIFICATION OF T-SOLT

The size of T-Solt on table as Fig 6:

For 31/31N2F For 25

16. MAINTAINING

That's easier to keep machine in good condition or best performance by means of maintaining it at

any time than remedy it after it is out of order.

(1) Daily Maintenance (by operator)

(a) Fill the lubricant before starting machine everyday.

(b) If the temperature of spindle caused over-heating or strange noise, stop machine immediately

to cheek it for keeping accurate performance.

(c) Keep work area clean; release vise, cutter, work-piece from table; switch off power source;

take chip or dust away from machine and follow instructions lubrication or coating rust proof

oil before leaving.

(2) Weekly Maintenance

(a) Clean and coat the cross leading screw with oil.

(b) Check to see if sliding surface and turning parts lack of lubricant. If the lubricant is

insufficant, fill it.

(3) Monthly Maintenance

(a) Adjust the accurate gap of slide both on cross and longitudinal feed.

(b) Lubricate bearing, worm, and worm shaft to avoid wear.

(4) Yearly Maintenance

(a) Adjust table to horizontal position for maintenance of accuracy.

(b) Check electric cord, plugs, switches at least once a year to avoid loosening or wearing.

17. CLEANING & LUBRICATING

(1) Your machine has been coated with a heavy grease to protect it in shipping. This coating should

be completely removed before operating the machine. Commercial degreaser, kerosene or

similar solvent may be used to remove the grease from the machine, but avoid getting solvent

Loading...

Loading...