3

OPERATING INSTRUCTIONS

PARTS REPLACEMENT

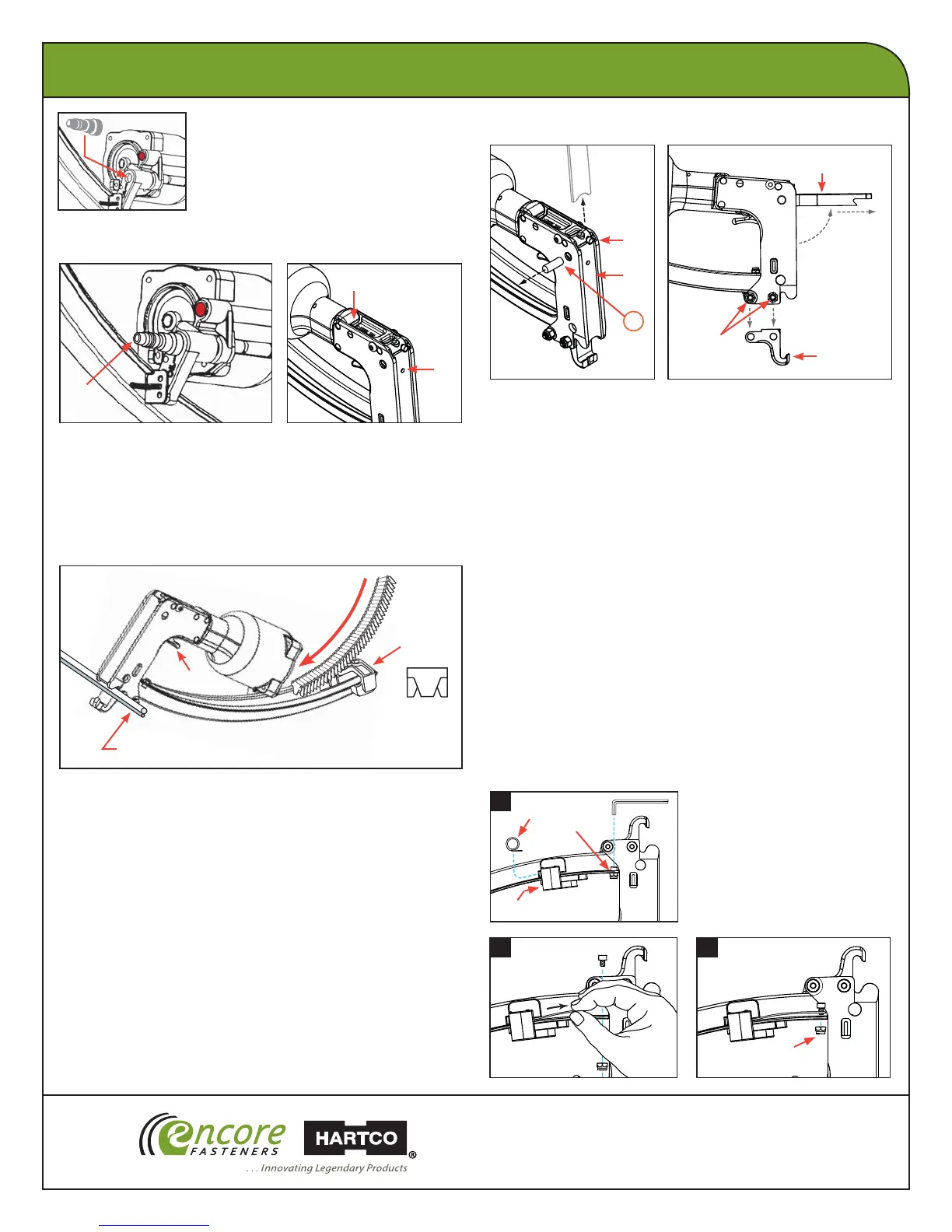

BLADE: Disconnect air. Remove clips from tool.

1. Depress pin

(F) at top of front plate (G); slide plate up and remove.

2. Swing blade

(H) from tool and align link pin (I) with holes in side

plates. Remove pin through holes and take out old blade.

3. Lubricate new blade.

4. With new blade at 90° angle, align blade hole with links and side plate

holes on either side. Insert link pin through aligned holes to secure

blade. Firmly strike blade face to swing back into original position.

5. Re-lubricate front plate. Depress pin

(F) and slide front plate down

until pin

is released, securing plate in place.

ANVIL: Disconnect air. Remove clips from tool.

1. Remove lower shoulder screws

(J) or pins/e-clips if tool is

a “T” model.

2. Remove old anvil

(K) and replace.

PUSHER SPRING: Disconnect air. Remove clips from tool.

For better access, turn tool upside down.

1. Loosen screw

(L) with a 9/64" hex key (allen wrench) and remove

damaged pusher spring from magazine. Insert new spring

(M) into

back of pusher

(P).

TO GET STARTED

Install a ¼” NPT tting (not included) into air

inlet opening in the back of the housing, using

suitable thread sealant. DO NOT REMOVE

RED PLUG LOCATED ABOVE THIS OPENING.

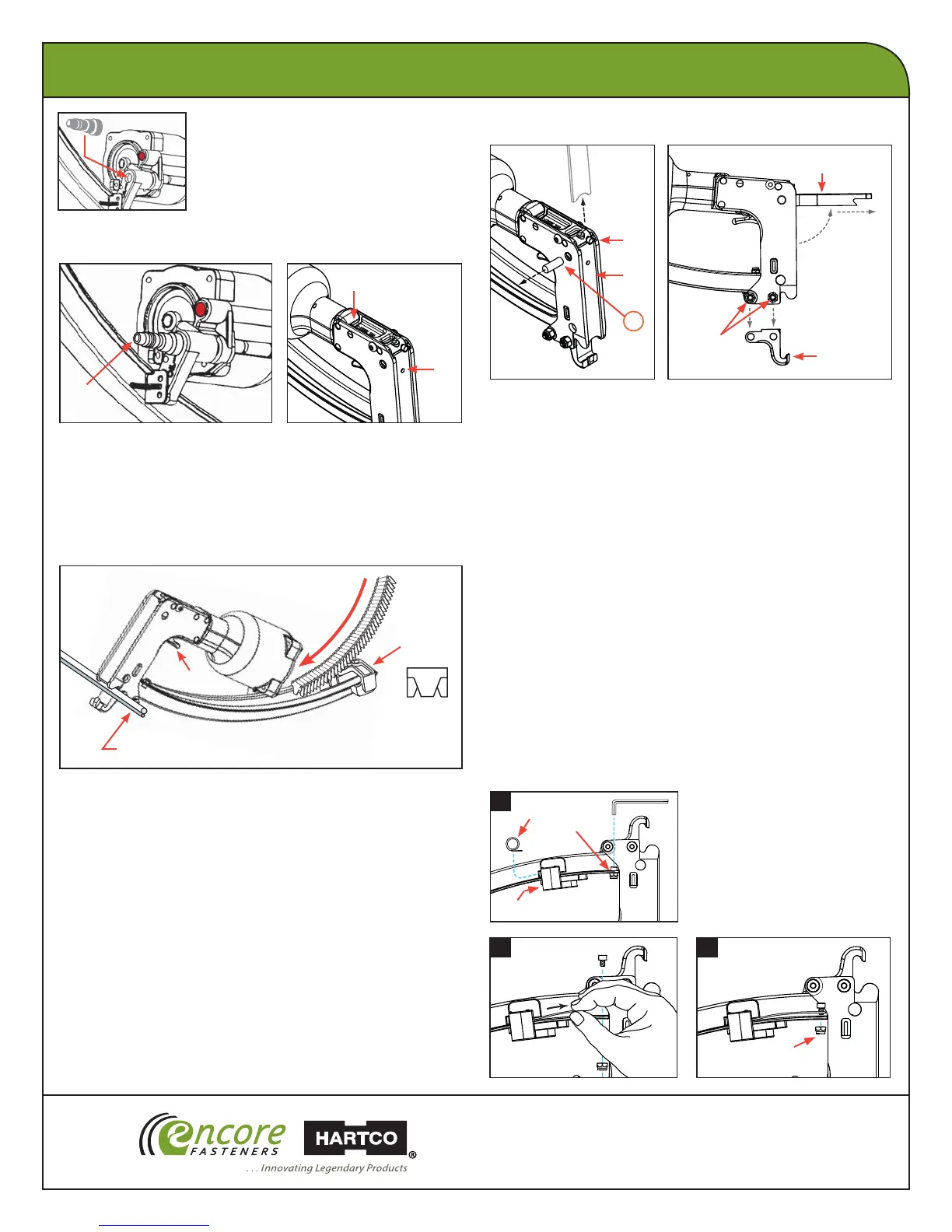

RECOMMENDED DAILY MAINTENANCE

Add 2-3 drops of air tool oil (10-weight recommended) to air inlet hose

tting

(A); and openings between the side plates at these two locations:

• in the gap at the back of the top plate and the housing

(B)

• the opening on the front plate (C), as shown on a xed label

TOOL OPERATION

1. Connect air supply to hose tting, keeping ngers and hands away

from blade and anvil area. Recommended air supply is 80-90 psi

(5.5–6.2 bars) of dry, lubricated air.

Eclipser air consumption (SCFM), assuming 90psi and 1 cycle per

second, is 3.56. Assuming 80psi and 1 cycle per second, SCFM is 3.22.

2. Load clips into magazine.

3. Set wires to be fastened into side plate notches. For best results,

smaller wire should be on the bottom. Squeeze trigger

(D) to

install clip.

LOADING CLIPS:

1. Pull pusher

(E) back until it latches at the end of magazine.

2. Remove strip of clips from box. Load entire strip into magazine with

the single “ear” facing towards the front of the tool.

3. Secure clips in place by depressing pusher latch on underside

of magazine.

www.encorehartco.com • info@encorefasteners.com

Northbrook, Illinois 60062 U.S.A.

Phone: 224-723-5524 • Fax: 224-723-5526

B

A

C

N

E

SINGLE

EAR FACES

FRONT OF

TOOL

SMALLER WIRE ON BOTTOM

D

2. Pull spring out from pusher with

ngers or by using the screw.

Align the spring hole with the

magazine screw hole. Insert

screw and secure with nut

(N).

Be careful not to deform spring.

3. Pull pusher back and latch at

end of magazine.

F

G

I

v. 08-11-16

ANVIL

J

BLADE

H

DIRECTION

SHOWN TO

REMOVE

PART(S).

REVERSE TO

PUT IN NEW

PART

K

1

2

L

M

P

Loading...

Loading...